Multilayer films prepared from blends of high-impact polyethylene and Ziegler-Natta-catalyzed polyethylene and high-pressure low-density polyethylene

A polyethylene and multi-layer film technology, which is applied in the direction of synthetic resin layered products, layered products, transportation and packaging, etc., can solve the problems of impact strength loss and low impact strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] Polyethylene

[0059] HI polyethylene has a melt index I of 0.65 g / 10 minutes 2 ; Density of 0.916g / cc; and SCBDI greater than 70. It is a trademark of NOVA Chemicals Ethylene-octene copolymer sold by FPS016. The MatWeb Internet website reports a standardized impact strength of 711 / g / mil, which can be considered a typical value for a blown film with a thickness of 1 mil made from the HI polyethylene.

[0060] LD polyethylene is an ethylene homopolymer, which has a melt index of 2.3 and a density of 0.919. LF 0219 A is sold.

[0061] ZN polyethylene is an ethylene-butene copolymer, which has a melt index of 0.8 g / 10 minutes and a density of 0.921 g / cc, sold by NOVA Chemicals under the brand name NOVAPOL PF-Y821-CP. The standardized impact strength of the film prepared from this polyethylene is reported on the MatWeb Internet website as 94 g / mil, which can be considered typical.

[0062] experiment method

[0063] According to ASTM D1709 / A(F 50 Standard) The impact strength ...

Embodiment 1

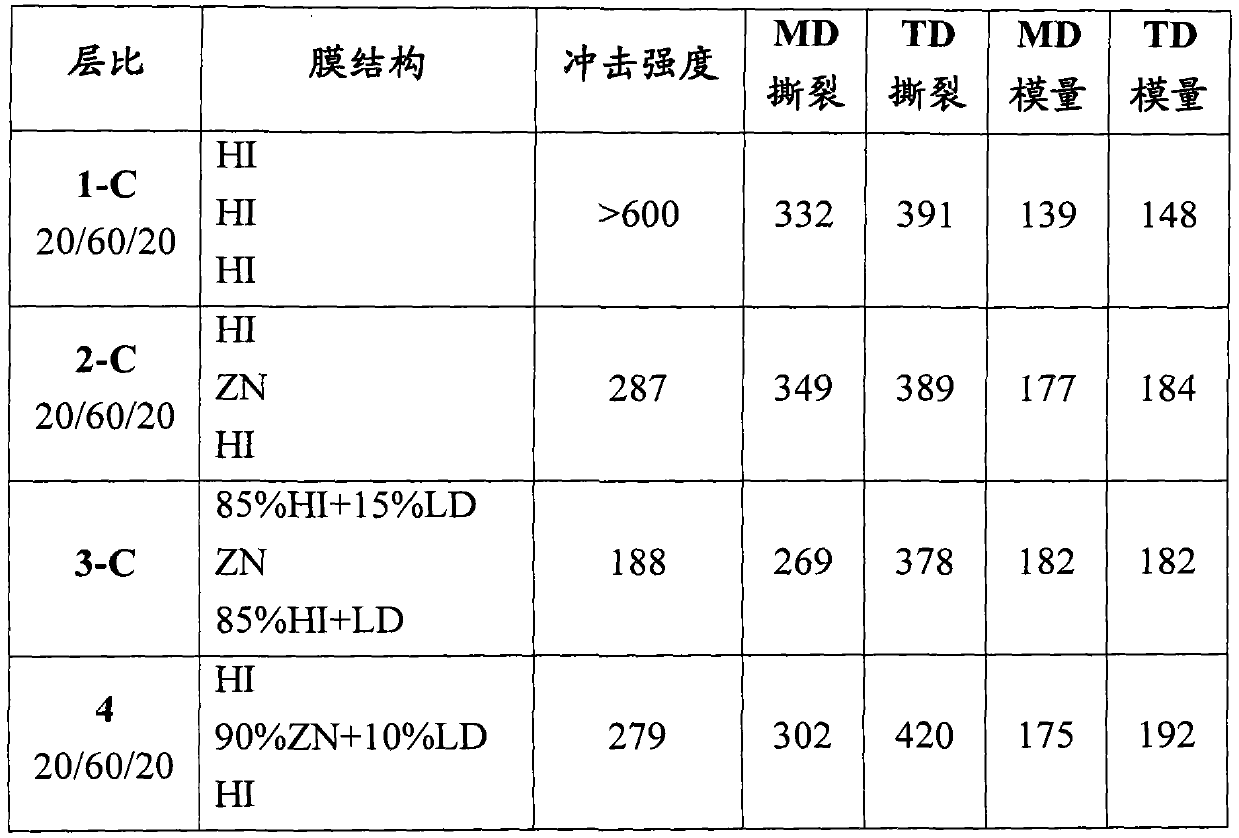

[0068] Example 1 The film was manufactured on a three-layer co-extruded film production line manufactured by Brampton Engineering. A blow up ratio (BUR) of 2.5 / 1 was used to prepare a three-layer film with a total thickness of 3 mils.

[0069] The A-B-C structures of these three-layer films are described in Table 1 in more detail. For the sake of clarity: the film 4 of the present invention has an A / B / C layer with a ratio of 20 / 60 / 20 (meaning that the surface layers A and C each contain 20% by weight of the total polyethylene, and the core layer B contains 60% by weight) . The surface layers (A and C) are each made of HI polyethylene, and the core layer is made of a blend of 90% ZN + 10% LD.

Embodiment 2

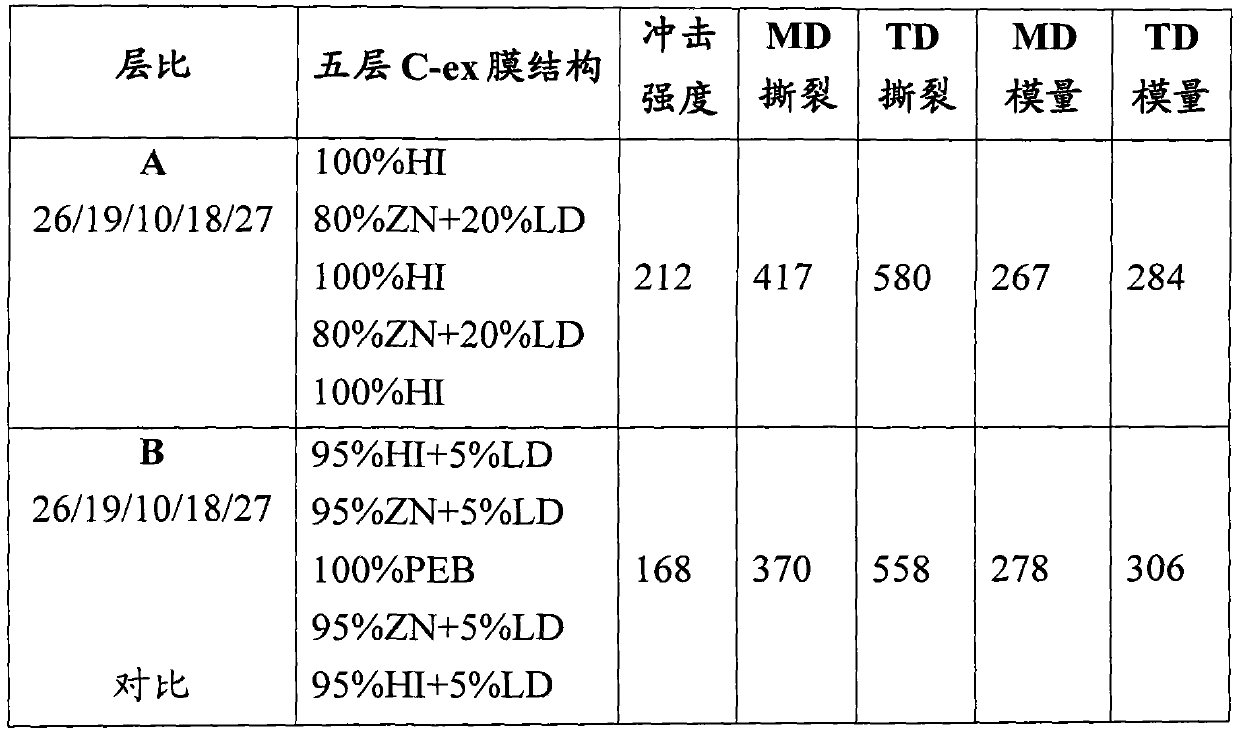

[0070] Example 2 A five-layer film was prepared on a blown film line fed by five extruders. The structure of A / B / C / D / E is clearly defined in Table 2. The film has a thickness of 3.5 mils and is prepared using 2.5 / 1 BUR.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com