Branch pruning mechanical arm

A technology of robotic arms and branches, applied in the field of robotic arms for pruning branches, can solve the problems of high labor intensity, low efficiency, and difficult branches, etc., and achieve the effect of high operating efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

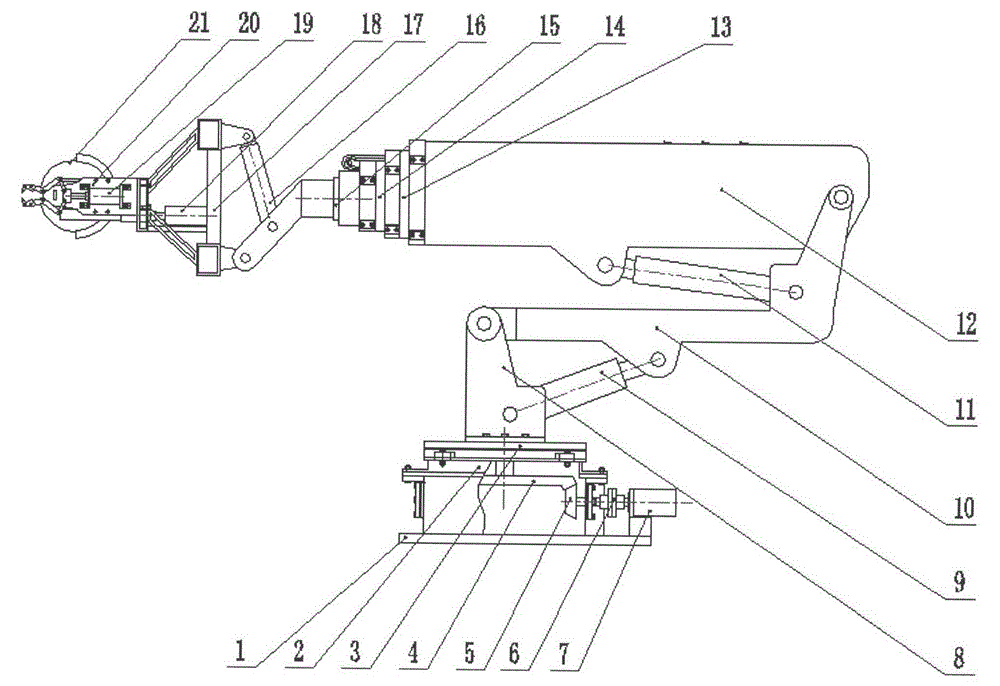

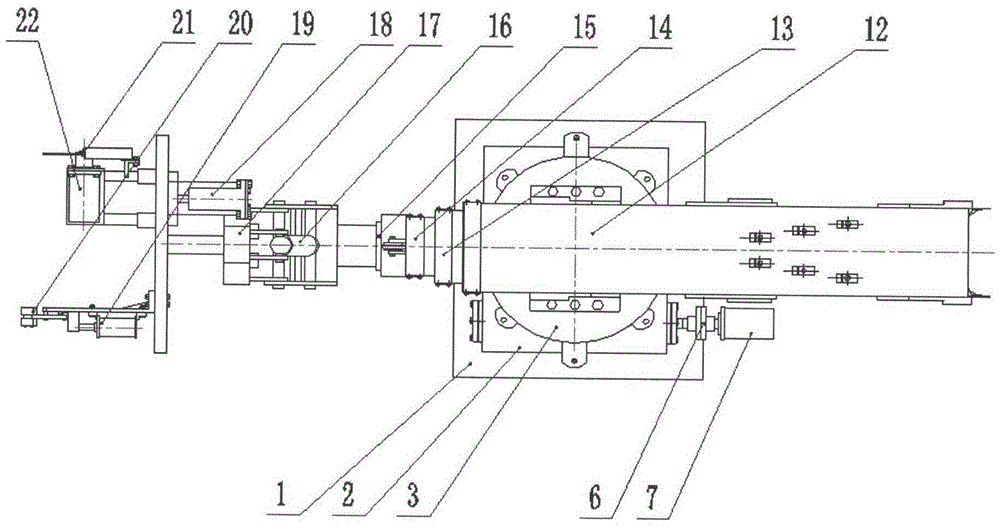

[0009] Such as figure 1 , a mechanical arm for branch pruning is composed of a base 1, a seat cover 2, a rotary table 3, a large bevel gear 4, a small bevel gear 5, a coupling 6, a motor 7, a stand 8, and a lower arm lifting cylinder 9. Lower arm 10, telescopic arm lifting cylinder 11, first section telescopic arm 12, second section telescopic arm 13, third section telescopic arm 14, swivel head 15, working head swing angle oil cylinder 16, working head bracket 17, circle Circular saw telescopic oil cylinder 18, manipulator claw drive oil cylinder 19, manipulator claw 20, circular saw 21, circular saw drive hydraulic motor 22 form. When pruning branches, the hydraulic power system first drives the telescopic arm lifting cylinder 11 to extend, so that the telescopic arm is erected, and the telescopic arm is driven by the traction cable or rack and pinion to stretch out one by one. If the telescopic arm is fully extended, it still cannot reach For the branches to be trimmed, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com