Full-automatic vehicle washing equipment

A fully automatic and equipment technology, applied to vehicle exterior cleaning devices, brushes, household appliances, etc., can solve problems such as poor self-cleaning ability, easy to hold cloth wheels, and vehicle paint surface wear, etc., to achieve strong self-cleaning ability, Highly dehydrated, soft bristles effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

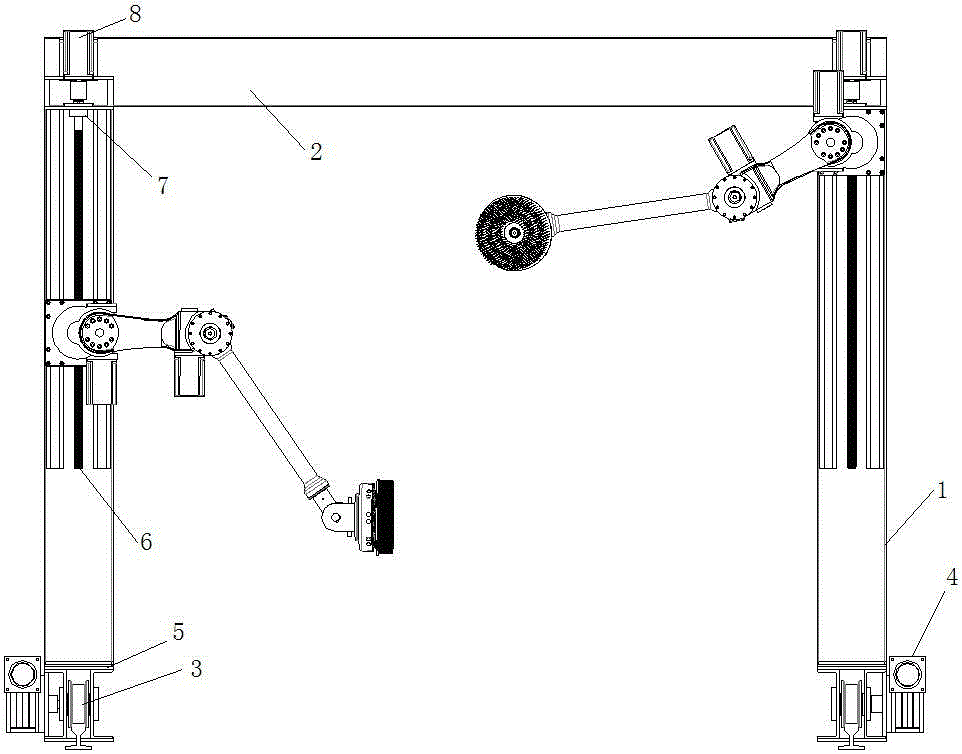

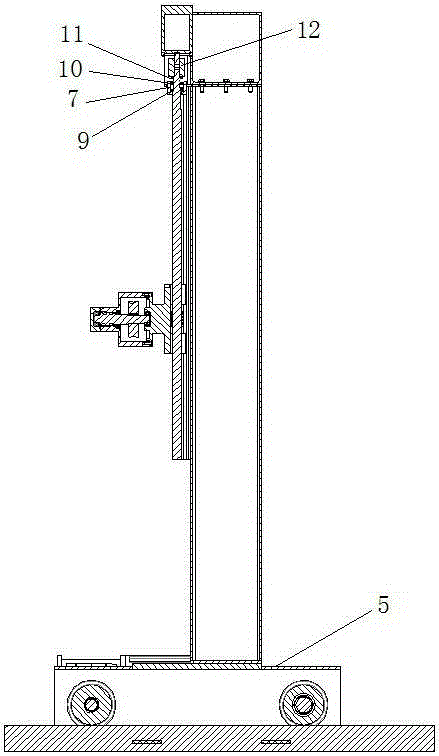

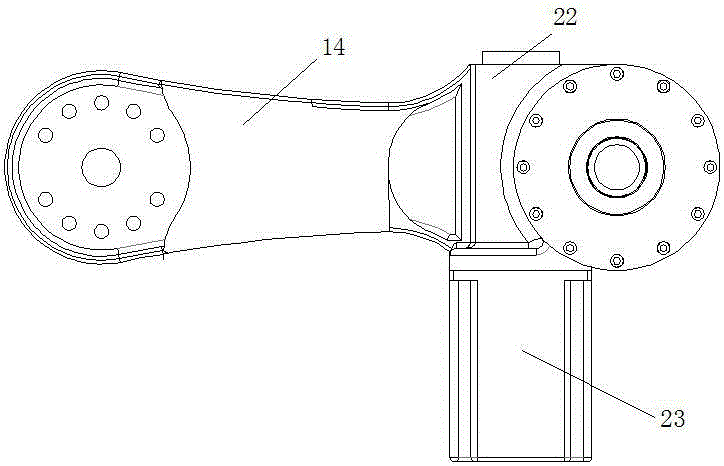

[0031] like Figure 1-2 As shown, the fully automatic car washing equipment is composed of a crane and two mechanical arms symmetrically installed on the crane; 6. The bearing seat 7 and the screw stepping motor 8, two T-shaped guide rails 3 are parallel, the column 1 is installed on the T-shaped guide rail 3 through the base 5, the beam 2 is installed on the top of the column 1, and the screw rod stepping is fixedly installed on the beam 2 Motor 8, ball screw 6 installed in column 1, the top of ball screw 6 is connected to screw stepper motor 8 through bearing seat 7, plane thrust bearing 9, deep groove ball bearing 10, lock nut 11 and coupling 12 , the base 5 is connected to the driving gearbox 4; the mechanical arm is composed of a large arm 14, a small arm 15, a rotating head 16 and a brush head 17, and a cylindrical guide rail 18 is installed in the column 1, and one end of the large arm 14 passes through the guide rail slider 19 and ball nut 20 are installed on the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com