Sulfur-arsenic adsorbent and preparation method thereof

An adsorbent and binder technology, which is applied in the field of sulfur and arsenic adsorbents and its preparation, can solve the problems of low sulfur capacity and arsenic capacity, and high bulk density of sulfur and arsenic adsorbents, so as to improve the arsenic capacity and increase the chance of interfacial contact. , Improve the effect of sulfur capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

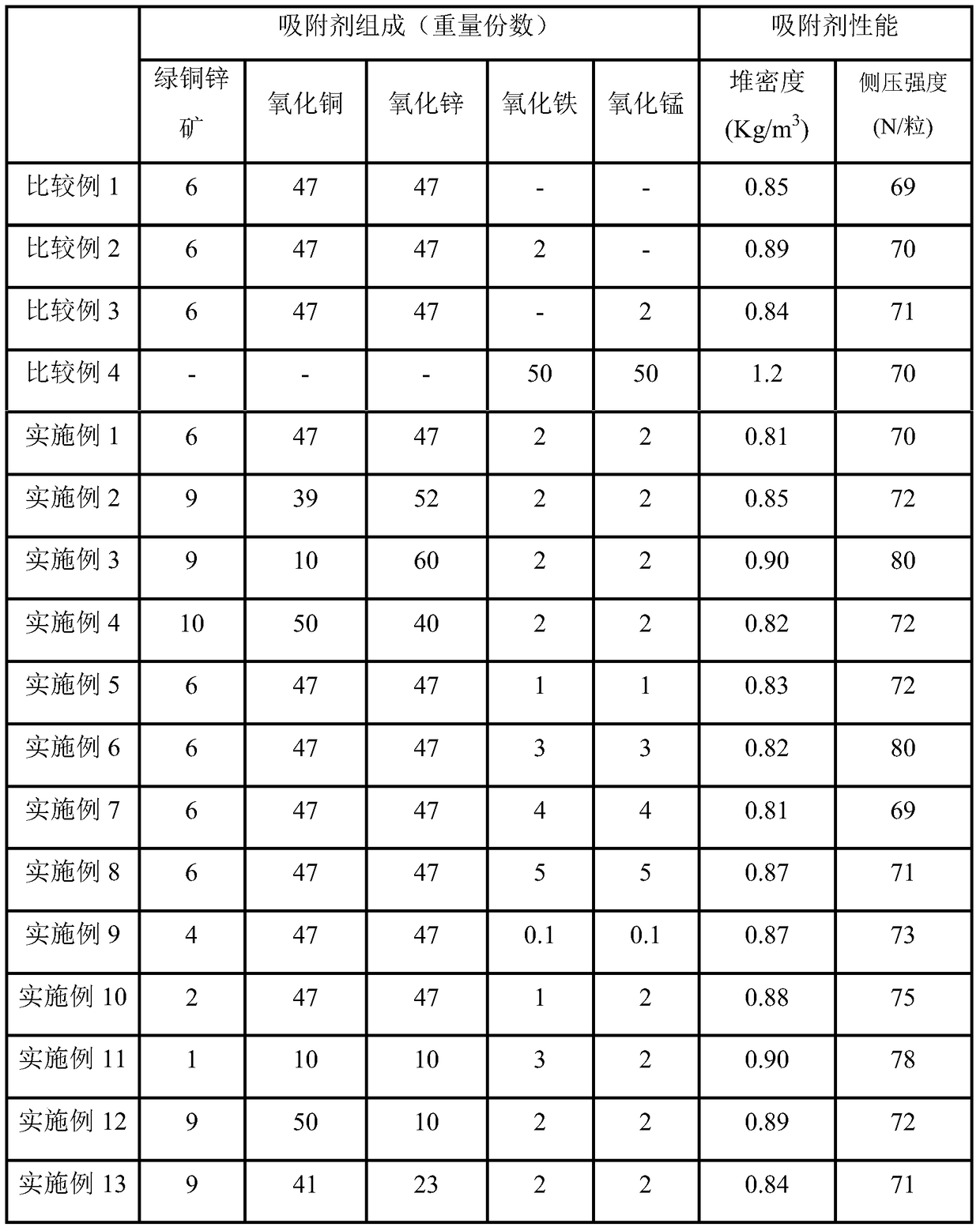

[0031] Mix 30 kilograms of copper nitrate, 40 kilograms of zinc nitrate, 10 kilograms of aluminum nitrate, 2 kilograms of iron nitrate, 1.75 kilograms of manganese nitrate 50% aqueous solution and 500 kilograms of water and mix and stir evenly to obtain a metal salt solution, mix 30 kilograms of sodium carbonate and 550 kilograms of water Uniformly obtain a sodium carbonate solution, mix the sodium carbonate solution and the metal salt solution uniformly, react at 70°C for 1 hour, wash and dry the precipitate, then add 6 kg of alumina, 1 kg of graphite, mix and roll, and then add 30% by weight of Water, granulation, calcination at 270°C for 2 hours, tablet molding, the composition of the obtained sample is shown in Table 1.

Embodiment 2

[0033] Mix 20 kilograms of copper nitrate, 50 kilograms of zinc nitrate, 10 kilograms of aluminum nitrate, 2 kilograms of iron nitrate, 1.75 kilograms of manganese nitrate 50% aqueous solution and 500 kilograms of water to obtain a metal salt solution, mix 30 kilograms of sodium carbonate and 550 kilograms of water Uniformly obtain a sodium carbonate solution, mix the sodium carbonate solution and the metal salt solution uniformly, react at 60°C for 2 hours, wash and dry the precipitate, then add 5 kg of alumina, 1 kg of graphite, mix and roll, and then add 35% by weight of Water, granulation, calcination at 270°C for 2 hours, tablet molding, the composition of the obtained sample is shown in Table 1.

Embodiment 3

[0035]Mix 10 kilograms of copper nitrate, 60 kilograms of zinc nitrate, 10 kilograms of aluminum nitrate, 2 kilograms of iron nitrate, 1.75 kilograms of manganese nitrate 50% aqueous solution and 500 kilograms of water to obtain a metal salt solution, mix 30 kilograms of sodium carbonate and 550 kilograms of water Uniformly obtain a sodium carbonate solution, mix the sodium carbonate solution and the metal salt solution uniformly, react at 60°C for 2 hours, wash and dry the precipitate, then add 6 kg of alumina, 1 kg of graphite, mix and roll, and then add 50% by weight of Water, granulation, calcination at 270°C for 2 hours, tablet molding, the composition of the obtained sample is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com