High-voltage discharge unit and air purifier

An air purifier and high-voltage discharge technology, which is applied in the field of air purification, can solve the problems of high maintenance cost, large wind resistance, high-efficiency filter screen and easy saturation of activated carbon adsorption, and achieve the effects of avoiding breakage, improving reliability and improving discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

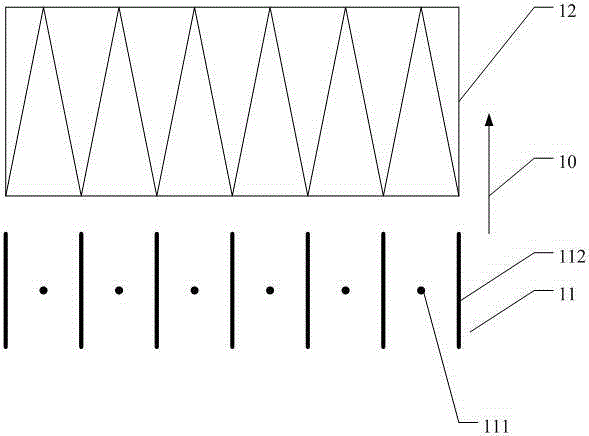

Image

Examples

Embodiment Construction

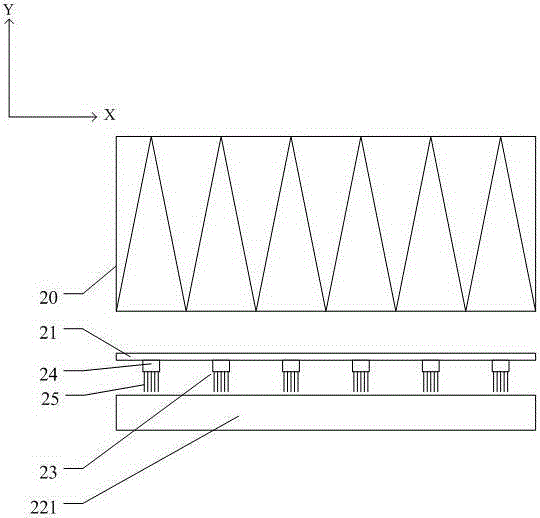

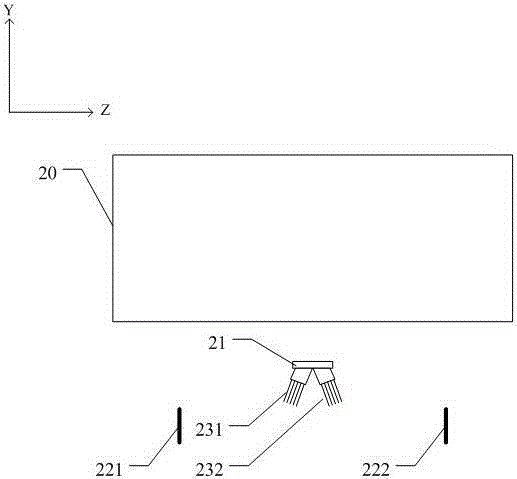

[0017] For the convenience of description, this embodiment establishes a three-dimensional Cartesian coordinate system, such as figure 2 and image 3 As shown, the direction of air flow is the positive direction of the Y axis.

[0018] Such as figure 2 As shown, the high voltage discharge unit of this embodiment includes a circuit board 21 connected to a high potential, a first pole plate 221 and a second pole plate 222 respectively grounded, and a plurality of carbon fiber bundles 23 electrically connected to the circuit board 21 . The first pole plate 21 and the second pole plate 222 are arranged along the Z axis, and the plurality of carbon fiber bundles 23 are arranged along the X axis.

[0019] The carbon fiber bundle 23 includes a fixed end 24, which is welded on the circuit board 21, so that the carbon fiber bundle 23 is connected to a high potential. The carbon fiber bundle includes a plurality of carbon fibers 25, and in order to improve the discharge effect, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com