An assembly jig for opening and closing toggle arms

A technology for assembling jigs and fixtures, which is applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of time-consuming, labor-intensive, high cost, and low device matching efficiency, and achieve the effects of safe and convenient operation, uniform distribution and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The patent is described in detail below in conjunction with the accompanying drawings.

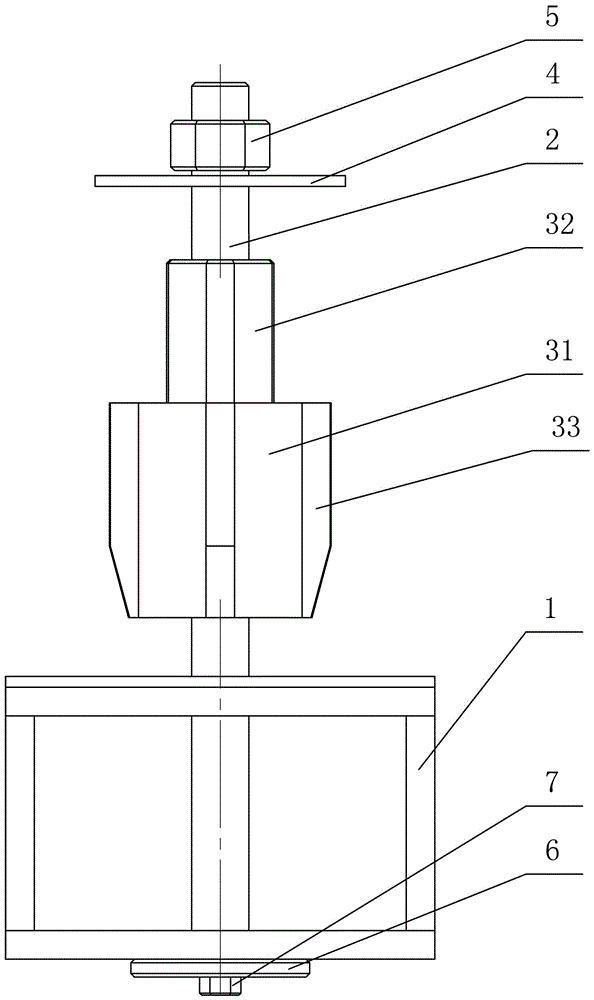

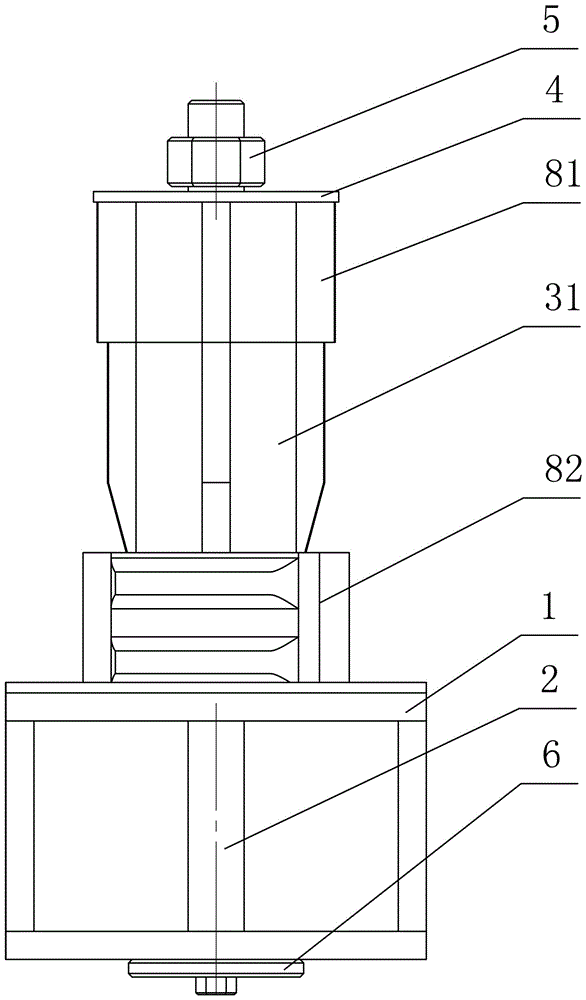

[0013] Such as figure 1 As shown, the present invention is an assembly jig for opening and closing crank arms, which is convenient for assembling the bushing 81 with the bushing hole 811, the crank arm frame 82 and several buffer pieces 83 into the crank arm 8. The clamp includes a bottom frame 1. Screw rod 2, punch 3, pressure plate 4, nut 5, washer 6 and screw 7. in:

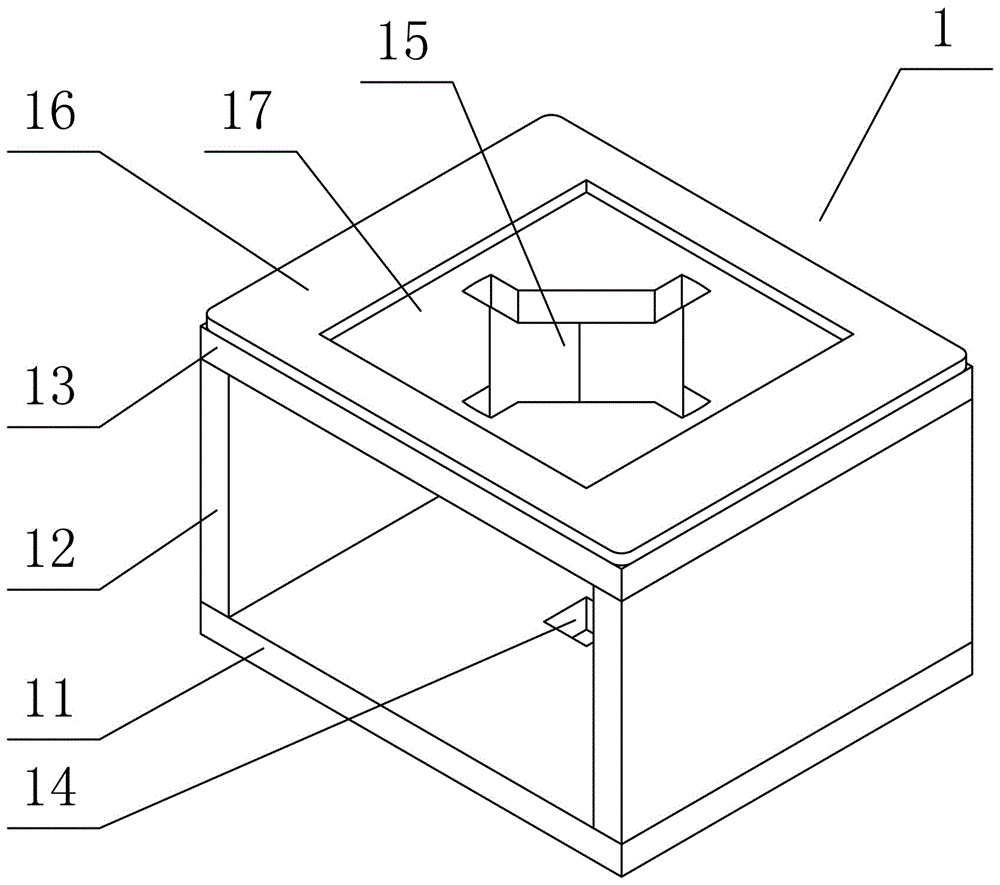

[0014] see in conjunction figure 2 , the underframe 1 is a hollow frame welded by a base plate 11, two side plates 12 and an upper plate 13, a square hole 14 is provided in the center of the base plate 11, and a shaft sleeve 81 with the crank arm 8 is provided in the center of the upper plate 13. The corresponding hollow opening 15 of the outer shape of the upper plate 13, and a positioning plate 16 is fixed above the upper plate 13, and a through hole 17 is provided in the center of the positioning plate 16. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com