Online automatic dynamic buffering system

A technology of dynamic buffering and driving wheels, applied in transportation, packaging, conveyors, etc., can solve the problems of reducing the utilization rate of filling machines and the loss of production line efficiency, and achieve the effect of improving production line efficiency, unique design and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

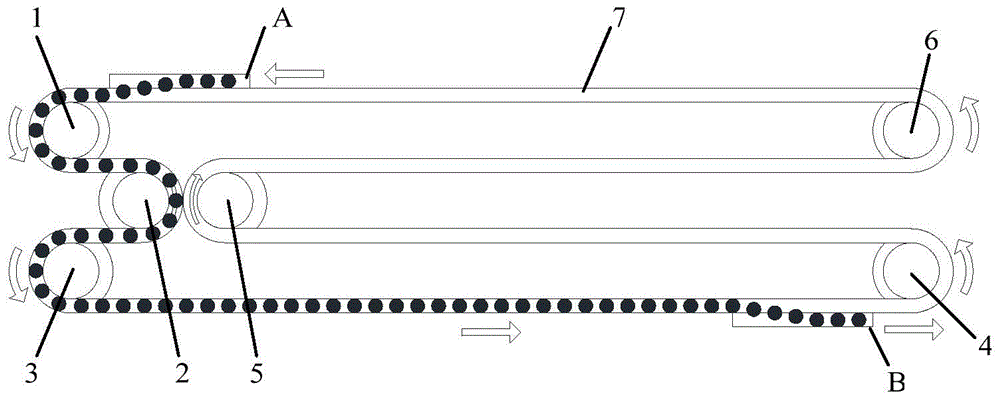

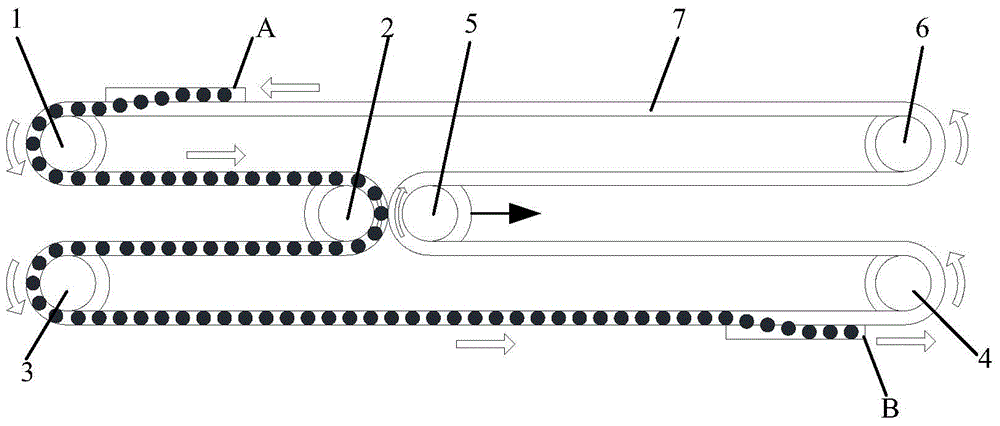

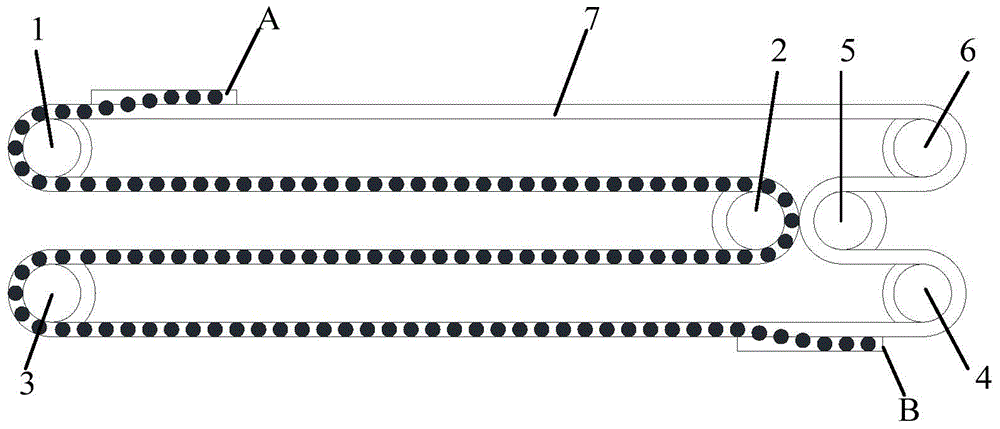

[0018] Below in conjunction with accompanying drawing, technical solution of the present invention will be further described:

[0019] Such as figure 1 As shown, the online automatic dynamic buffer system includes a closed-loop chain 7 and a first drive wheel 1, a first pulley 2, a first idler pulley 3, a second drive wheel 4, a second pulley 5, and a first pulley arranged in sequence along the forward direction of the chain. Two idler wheels 6, between the first driving wheel 1 and the second driving wheel 4 transmit power through the first idler wheel 3, between the second driving wheel 4 and the first driving wheel 1 transmit power through the second idler wheel 6, the second idler wheel 6 The rotation direction of the first pulley 2 and the second pulley 5 is the same, the rotation direction of the first driving wheel 1, the first idler wheel 3, the second driving wheel 4 and the second idler wheel 6 is the same, the first pulley 2 and the second pulley 5 The direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com