A kind of preparation method of epoxy phenolic nano anticorrosion coating

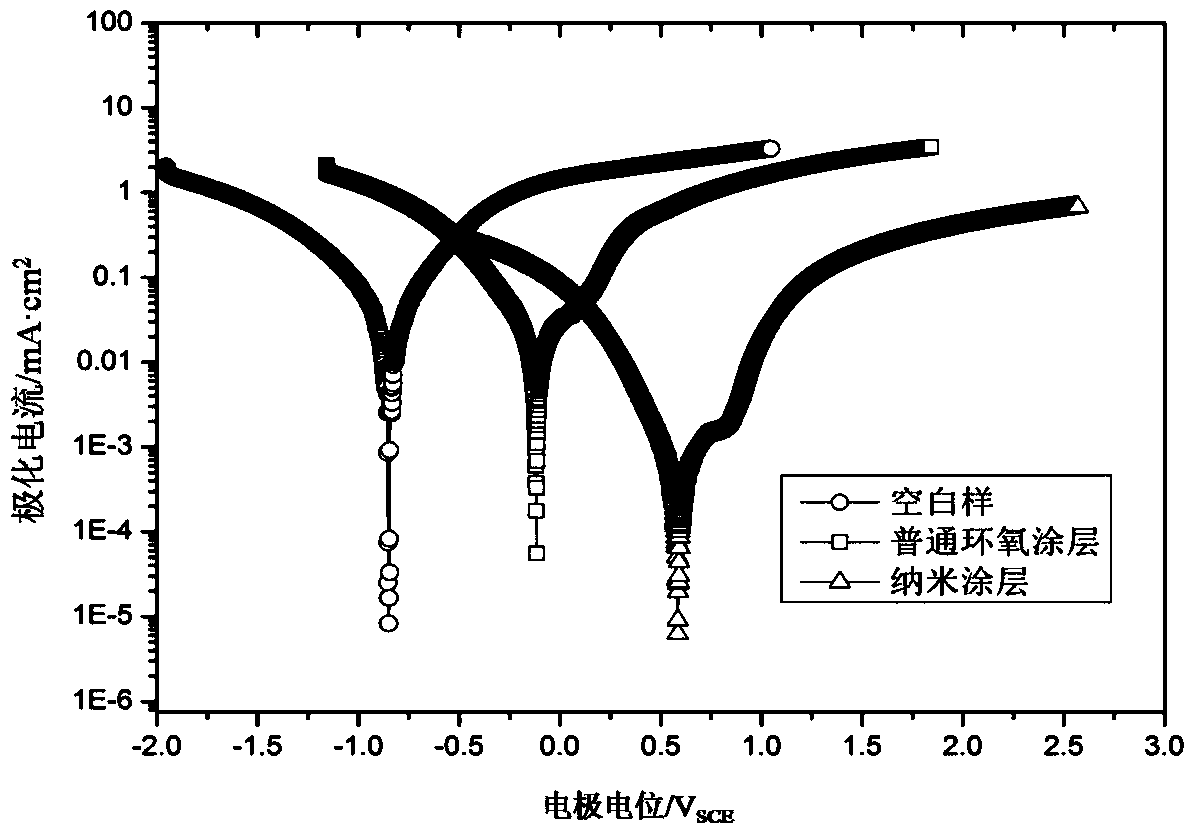

An anti-corrosion coating, epoxy phenolic technology, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of low curing shrinkage, slow curing reaction, low construction efficiency, etc., to achieve tight coating, barrier The effect of penetration and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in combination with specific embodiments.

[0030] The preparation method of a kind of epoxy phenolic nano anticorrosion coating of the present embodiment, comprises the steps:

[0031] Step 1: Prepare Component A:

[0032] ① Weigh the raw materials of component A according to the formula: 8% epoxy resin, 16% phenolic resin, 18% mixed solvent, 1.2% nano particles, 0.3% coupling agent KH-5500.3%, 6% zinc phosphate, 18% talcum powder, Organic bentonite 9%, precipitated barium sulfate 18%, defoamer 2.3%, leveling agent 1.6% and surfactant Triton X-100 1.6%;

[0033] ②Use a muffle furnace to calcinate nanoparticles at 600°C for 3 hours, add them to a three-necked flask after cooling, and disperse them with absolute ethanol to form a nanoparticle suspension with a mass fraction of 4.8%; stir for 10 minutes, and then add the modified coupling agent dropwise KH-550, raise the temperature to 130°C to modify the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com