A mold for sewing back pocket inserts of different sizes of trousers

A technology of inserting pockets and moulds, which is applied to sewing equipment, sewing machine components, textiles and papermaking, etc. It can solve the problems of complex sewing of inserts, high proficiency of workers and high technical level, and achieve cost saving, uniform width and position, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

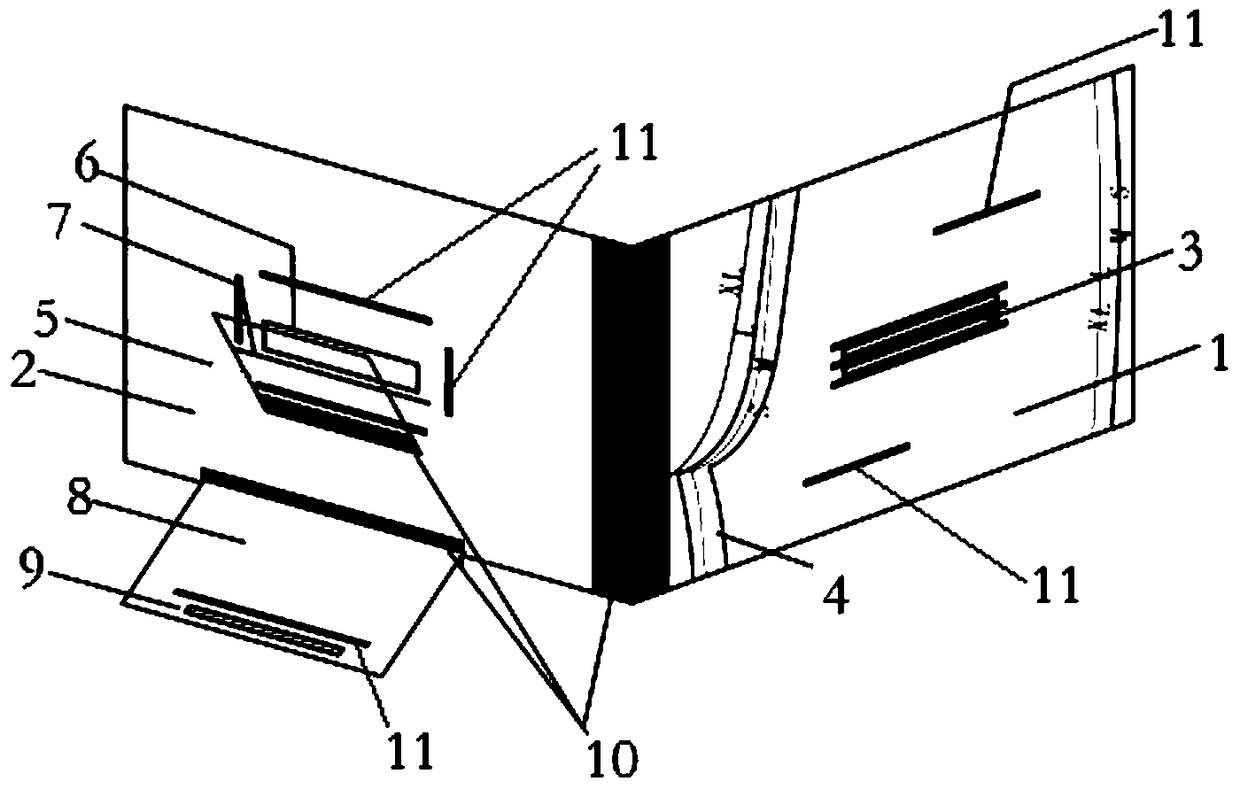

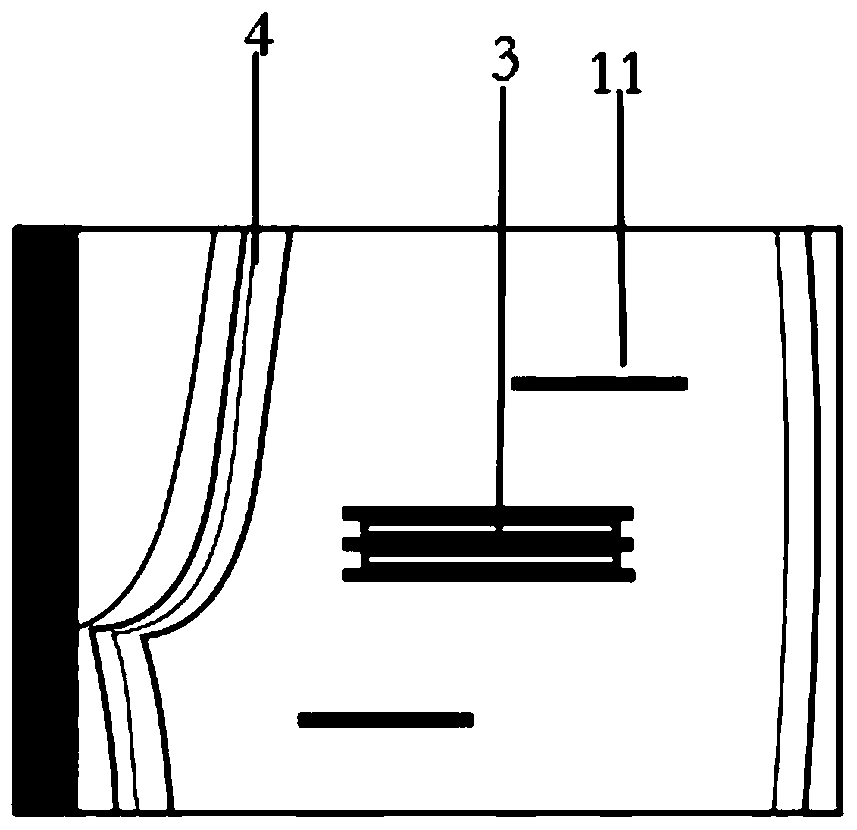

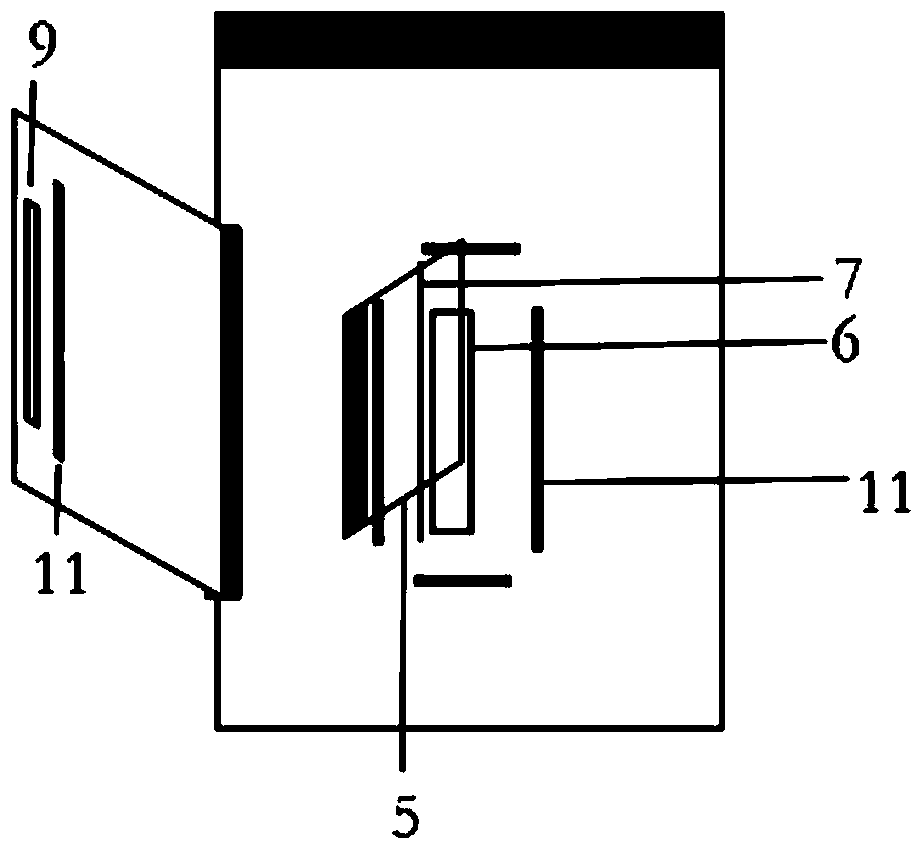

Method used

Image

Examples

Embodiment 2

[0028] The difference between this embodiment and the first embodiment is that the first template, the pressing plate and the cover plate are connected to the second template by a rotating shaft, and the mold also includes a controller and a motor drive mechanism for driving the rotating shaft to rotate. A plurality of infrared sensors are arranged in the routing direction of the positioning line, and the motor drive mechanism and the infrared sensor are both connected with the controller. The design of this structure is to control the mold more automatically and further save the labor of workers. The motor drive mechanism can be realized by an existing method. The motor drive mechanism drives the rotating shaft to rotate, thereby driving the first template, the pressing plate, the cover plate and the second template to flip between each other. The setting of multiple infrared sensors can place The signal of the work object is collected and transmitted to the controller, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com