Anti-staining member mounted on external corner of housing wall and construction method of anti-staining member

A technology of sun corners and walls, which is applied to building components, roofs, roof drainage, etc., can solve the problems of affecting the appearance of buildings, failing to reach drip tanks, and damage to drip tanks, so as to facilitate construction, avoid water marks, and improve structure beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

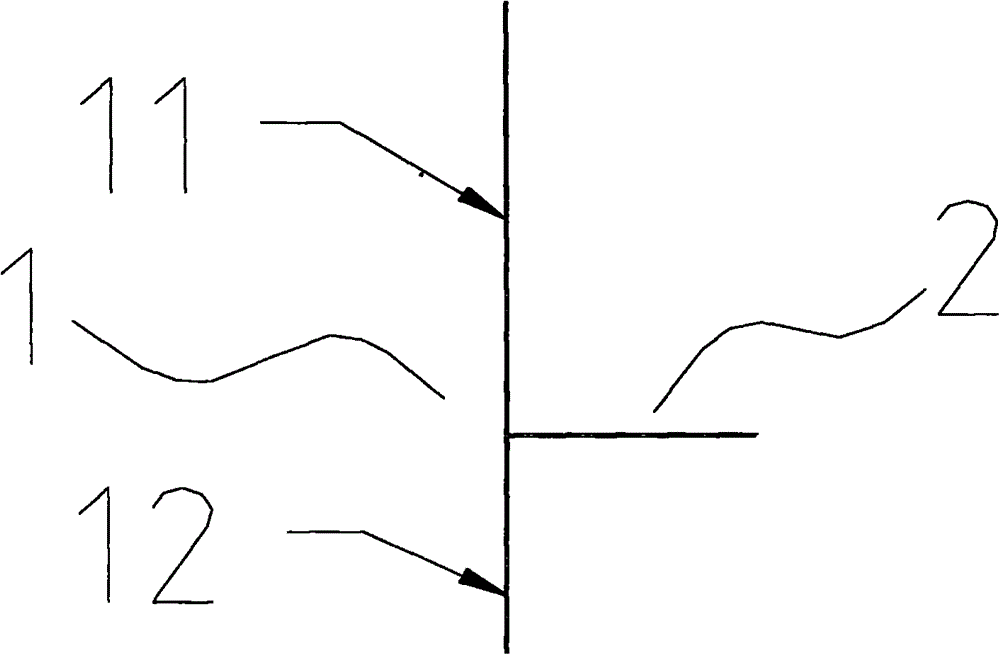

[0019] Embodiment 1 (T type)

[0020] The anti-fouling component installed on the upper corner of the house wall in the present invention is installed on the upper corner of the house wall. The upper corner is mainly composed of a vertical wall perpendicular to the ground plane and a horizontal horizontal The wall surface is composed of a water guide strip 1 for guiding rainwater and a positioning strip 2 for assisting the positioning and installation of the water guide strip; one end of the water guide strip is a water collection part 11 buried in the vertical wall surface, The other end of the water guide bar is a drainage part 12 for draining rainwater; one end of the positioning bar 2 is connected between the water collecting part 11 and the drainage part 12; the positioning bar 2 and the guide bar The included angle between the water strips 1 is a right angle; the water collecting part 11 has a plurality of through holes for fixing on the vertical wall, and the water coll...

Embodiment 2

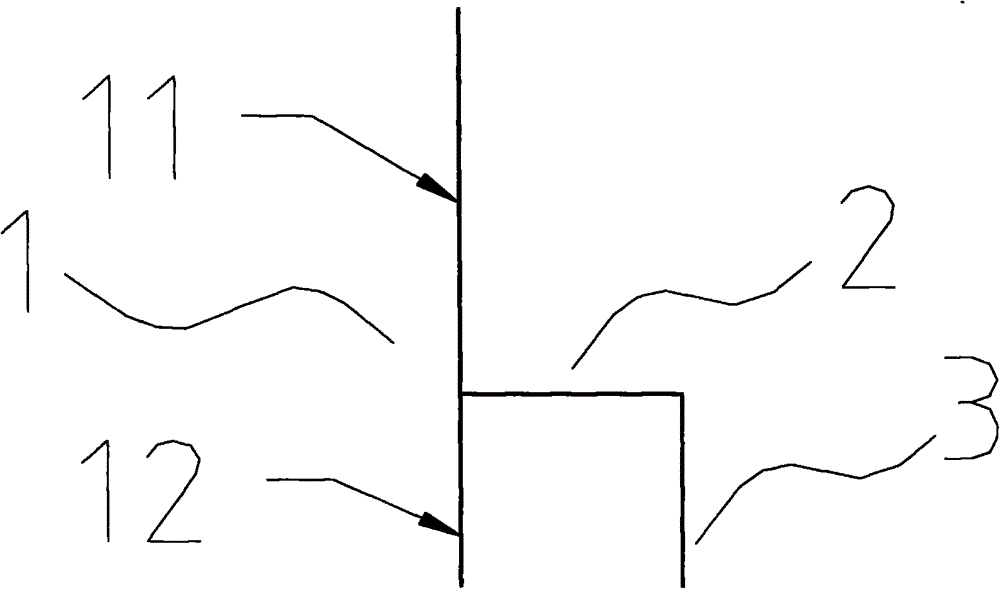

[0030] Embodiment 2 (h type)

[0031] The anti-fouling component installed on the upper corner of the house wall in the present invention is installed on the upper corner of the house wall. The upper corner is mainly composed of a vertical wall perpendicular to the ground plane and a horizontal horizontal The wall is composed of a water guide strip 1 for guiding rainwater and a positioning strip 2 for assisting the positioning and installation of the water guide strip 1; one end of the water guide strip 1 is a water collection part buried in the vertical wall 11. The other end of the water guiding strip 1 is a drainage part 12 for draining rainwater; one end of the positioning strip 2 is connected between the water collecting part 11 and the drainage part 12; the positioning strip 2 and the The included angle between the water guide strips 1 is a right angle; the water collecting part 11 is arrayed with several through holes for fixing with the vertical wall surface, and the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com