High-strength corrosion-resistant co-extruded film and preparation method thereof

A corrosion-resistant, co-extruded film technology, applied in the field of feeding bags, can solve the problems of easy leakage, easy corrosion of chemicals, low film strength, etc., and achieve the effects of improved acid, alkali and salt corrosion resistance, convenient control, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

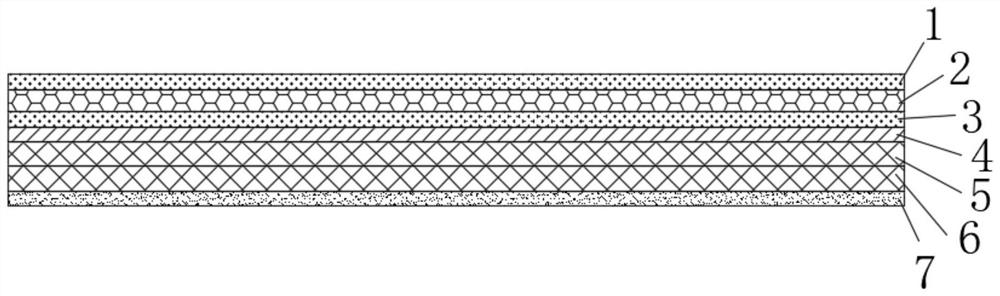

[0034] like figure 1 As shown, a high-strength corrosion-resistant co-extruded film includes a first PA barrier layer 1, an EVOH barrier layer 2, a second PA barrier layer 3, an adhesive layer 4, a first PP corrosion-resistant layer 5, and a second PA barrier layer arranged in sequence. Two PP corrosion-resistant layers 6 and PP sealing layers 7.

[0035] The raw material of the first PA barrier layer 1 and the raw material of the second PA barrier layer 3 are both made of a melting temperature of 230°C and a density of 1.13g / cm 3 nylon.

[0036] The EVOH barrier layer 2 is made of raw materials with an ethylene content of 35wt% and a density of 1.14g / cm 3 ethylene-vinyl alcohol copolymers.

[0037] The raw material of the adhesive layer 4 is formed by mixing the copolymerized PP carrier and the adhesive resin TIE at a weight ratio of 5:1.

[0038] The copolymerized PP carrier adopts a density of 0.92g / cm 3 , and a copolymerized polypropylene having a melt flow rate of 11...

Embodiment 2

[0050] A high-strength corrosion-resistant co-extruded film, including a first PA barrier layer, an EVOH barrier layer, a second PA barrier layer, an adhesive layer, a first PP corrosion-resistant layer, a second PP corrosion-resistant layer and a PP seal that are arranged in sequence Floor.

[0051] The raw material of the first PA barrier layer and the raw material of the second PA barrier layer are both made of a melting temperature of 220°C and a density of 1.08g / cm 3 nylon.

[0052] The EVOH barrier layer is made of raw materials with an ethylene content of 30wt% and a density of 1.10g / cm 3 ethylene-vinyl alcohol copolymers.

[0053] The raw material of the adhesive layer is formed by mixing the copolymerized PP carrier and the adhesive resin TIE in a weight ratio of 4:1.

[0054] The copolymerized PP carrier adopts a density of 0.90g / cm 3 , and a copolymerized polypropylene having a melt flow rate of 8 g / 10 min at 230° C. / 2.16 kg load.

[0055] The adhesive resin TI...

Embodiment 3

[0066] A high-strength corrosion-resistant co-extruded film, including a first PA barrier layer, an EVOH barrier layer, a second PA barrier layer, an adhesive layer, a first PP corrosion-resistant layer, a second PP corrosion-resistant layer and a PP seal that are arranged in sequence Floor.

[0067] Both the raw material of the first PA barrier layer and the raw material of the second PA barrier layer adopt a melting temperature of 250°C and a density of 1.18g / cm 3 nylon.

[0068] The raw material of the EVOH barrier layer adopts the ethylene content as 40wt%, density is 1.19g / cm 3 ethylene-vinyl alcohol copolymers.

[0069] The raw material of the adhesive layer is formed by mixing the copolymerized PP carrier and the adhesive resin TIE at a weight ratio of 6:1.

[0070] The copolymerized PP carrier adopts a density of 0.93g / cm 3 , and a copolymerized polypropylene having a melt flow rate of 15 g / 10 min at 230° C. / 2.16 kg load.

[0071] The adhesive resin TIE is maleic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com