Paper mold tableware forming machine and full-automatic paper mold tableware production equipment

A molding machine and tableware technology, applied in textiles and papermaking, can solve problems such as water marks and affecting product appearance quality, and achieve the effect of improving appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

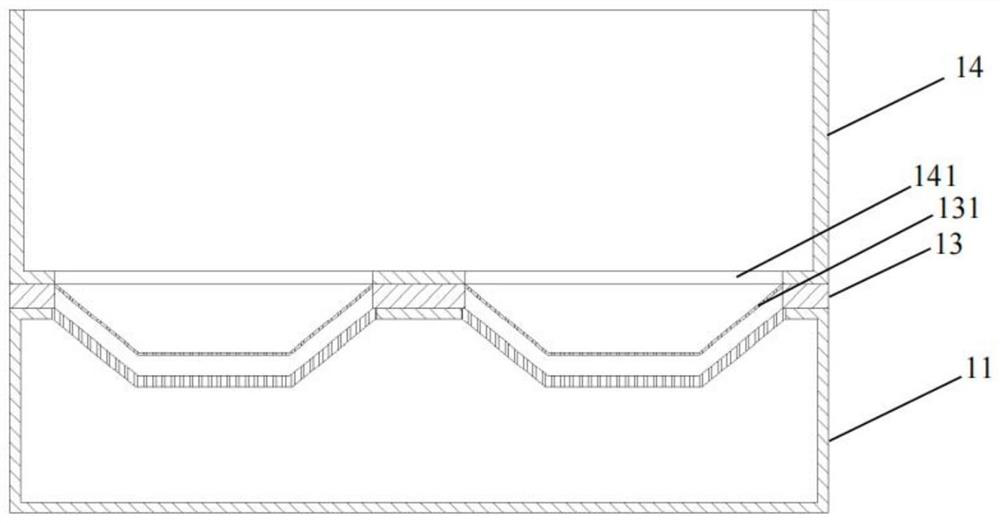

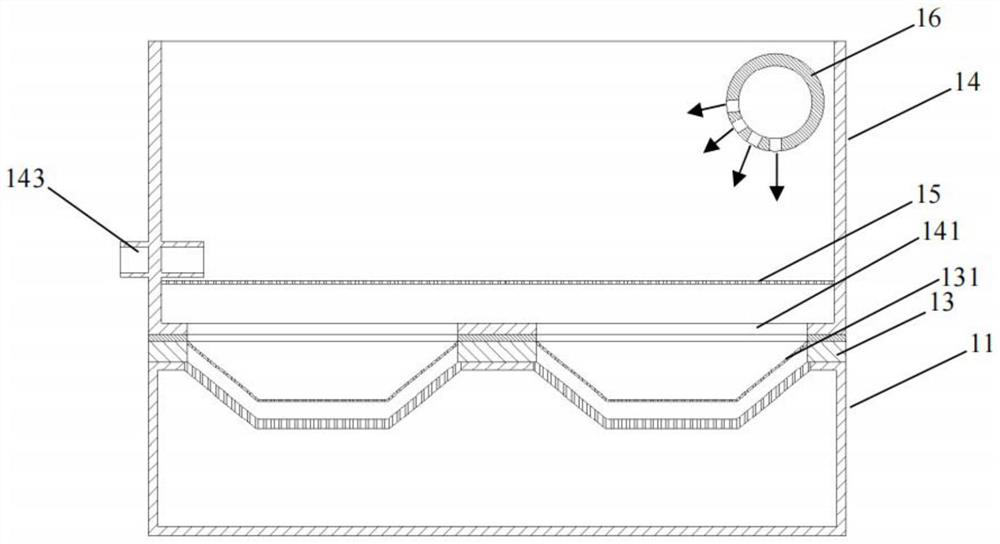

Embodiment Construction

[0016] After analysis, it is found that the pulp used in the production of paper mold tableware contains air bubbles, and the air bubbles gather above the liquid surface of the pulp. The paper mold tableware forming machine of the prior art cannot remove the air bubbles above the liquid surface of the pulp. As the process progresses, the pulp liquid level gradually drops to the formed paper mold tableware blank, and the air bubbles on the liquid surface are adsorbed on the formed paper mold tableware blank, and finally form water marks on the surface of the paper mold tableware finished product, which affects the appearance quality of the paper mold tableware.

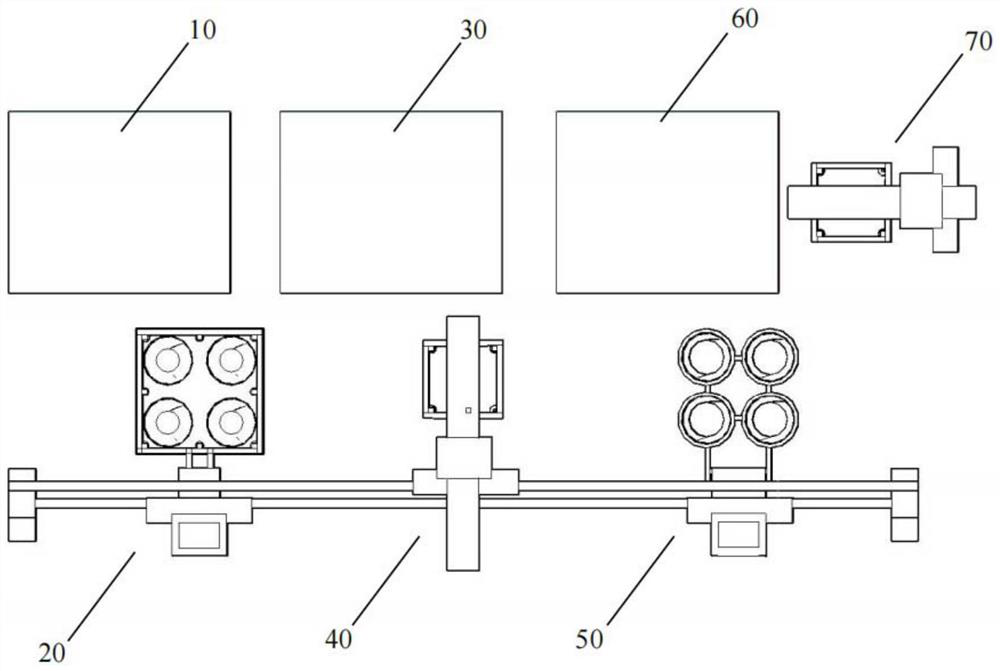

[0017] Such as figure 2 As shown, the automatic paper mold tableware production equipment of the present invention includes a paper mold tableware forming machine 10, a forming transfer manipulator 20, a dryer 30, a transfer manipulator 40, a trimming transfer manipulator 50, a trimming machine 60 and a finished produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com