A low-pressure circulating pump system for conveying paint

A low-pressure circulation and pump system technology, applied in the field of circulation pumps, can solve the problems of slow circulation speed, easy condensation of paint, and unsatisfactory effect, and achieve the effect of maintaining low-pressure environment, speeding up conveying rate, and good voltage stabilization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

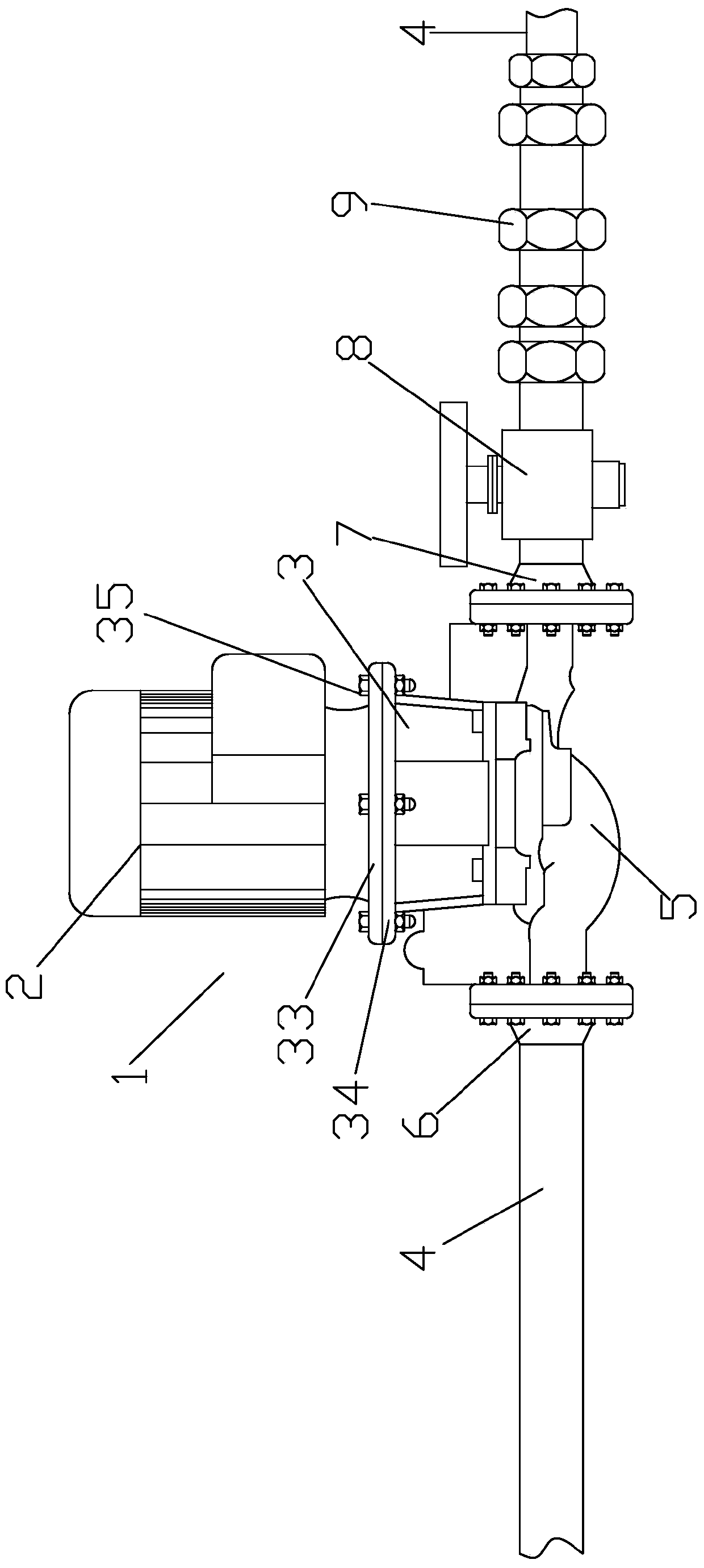

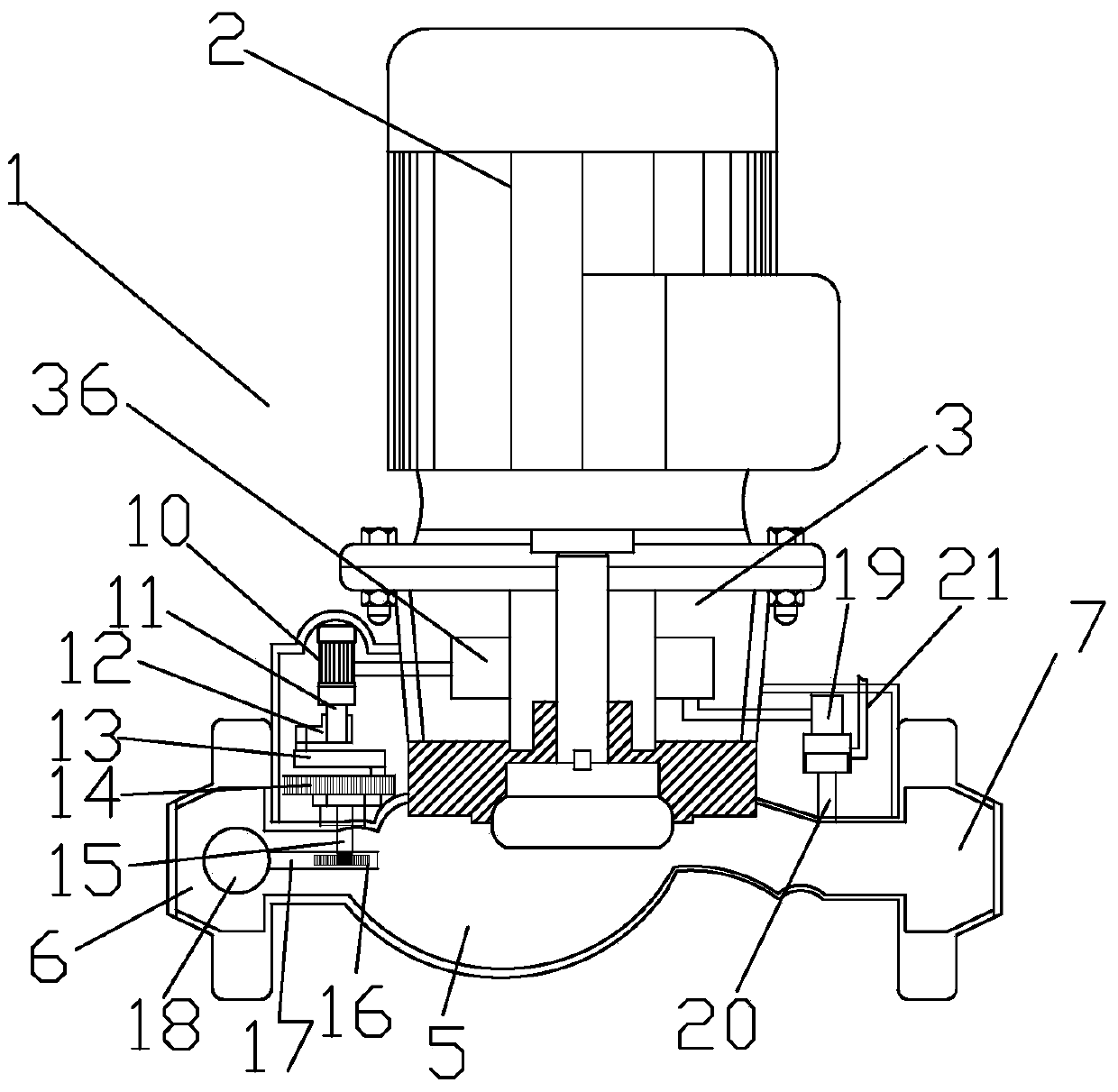

[0034] Such as Figure 1 to Figure 9 As shown, a low-pressure circulation pump system for conveying paint includes a circulation pump 1 and a circulation pipe 4. The circulation pump 1 includes a pump body 3 and a motor 2. A flange is connected between the pump body 3 and the motor 2. The flange Including the upper flange 33 and the lower flange 34, the upper flange 33 is connected to the motor 2, the lower flange 34 is connected to the pump body 3, and the upper flange 33 and the lower flange 34 are provided with screw holes (not marked in the figure) , bolts 35 are connected in the screw holes, and the upper flange 33 and the lower flange 34 are connected by means of bolts 35 . The pump body 3 and the motor 2 are connected through the upper flange 33 and the lower flange 34, the sealing effect is good, the connection is firm, and the motor 2 and the pump body 3 are detachable, which is convenient for replacement and daily maintenance.

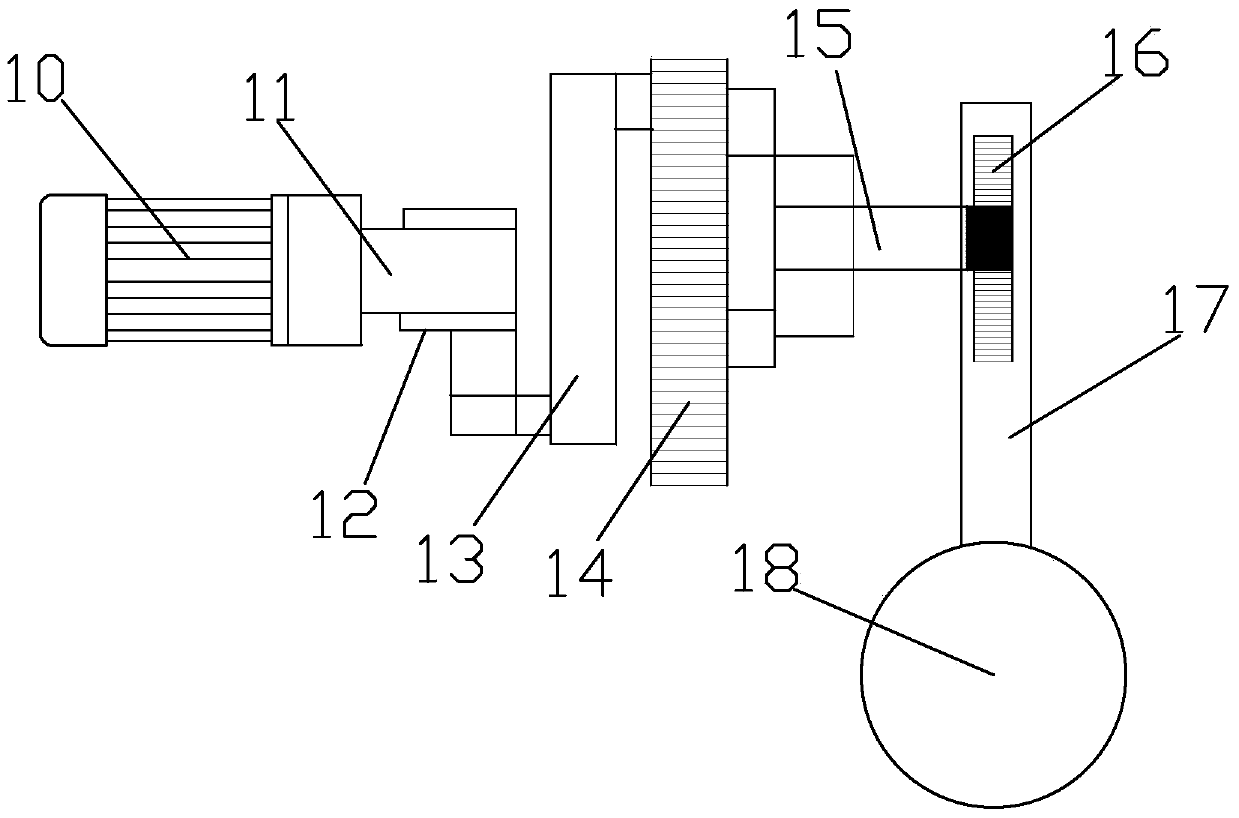

[0035] The pump body 3 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com