Stator curve verticality measuring instrument

A verticality measuring instrument and curve technology, which is applied in the direction of measuring devices, mechanical measuring devices, instruments, etc., can solve the problems that the measuring instruments cannot be measured, the measuring method is complicated, and errors are easy to occur, so as to reduce the production cost of the enterprise and simplify the operation , the effect of small error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

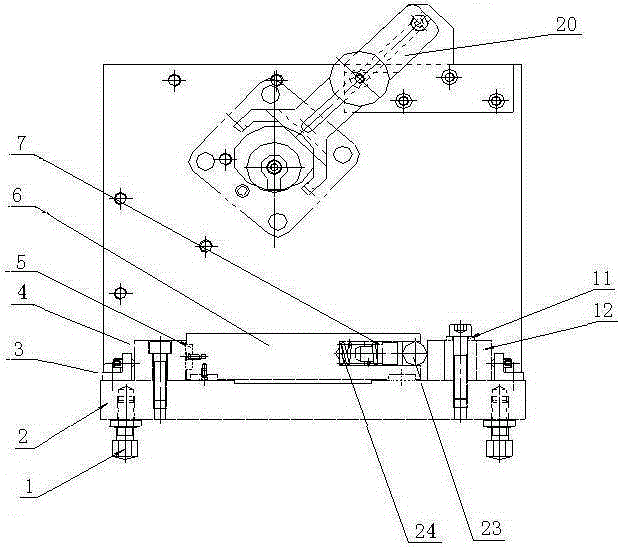

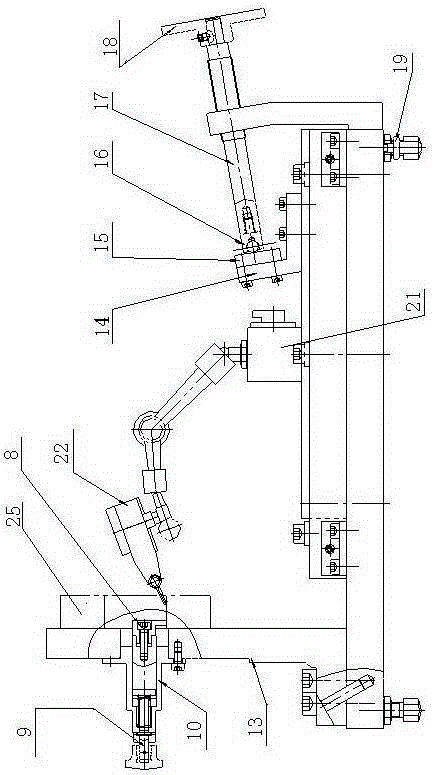

[0012] The structure of the stator curve perpendicularity measuring instrument of the present invention is as follows: figure 1 with figure 2 As shown, a slide plate 6 is installed on the base plate 2, a guide rail plate 5 is installed on one side of the slide plate 6, a spring 24, a guide shaft 7 and a steel ball 23 are installed on the other side of the slide plate 6, and the base plate 2 is located on the side of the guide rail plate 5 on the slide plate 6 Install the guide rail block 4, install the stopper 12 on the side of the steel ball 23 on the slide plate 6 on the bottom plate 2, install the washer 11 and the screw on the stopper 12, install the bent plate 3 on the side of the guide rail block 4 and the stopper 12, and fix it; on the bottom plate 2 Install the vertical plate 13, the limit block 8, the guide rod 9, and the clamping assembly 20 are installed on the vertical plate 13 to fix the detected stator 25; the magnetic gauge base 21 is installed on the slide pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com