Loading mechanism capable of increasing confining pressure and constraining rotation of sample

A technology of loading mechanism and loading pressure head, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., and can solve problems such as axial stress uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so as to facilitate people's understanding of the present invention. The specific structural forms of the present invention are not limited to the forms described in the following examples, and those skilled in the art can easily design other specific implementations according to the ideas expressed in the invention, but these specific implementations designed according to the content of the present invention are still Belong to the protection scope of the present invention.

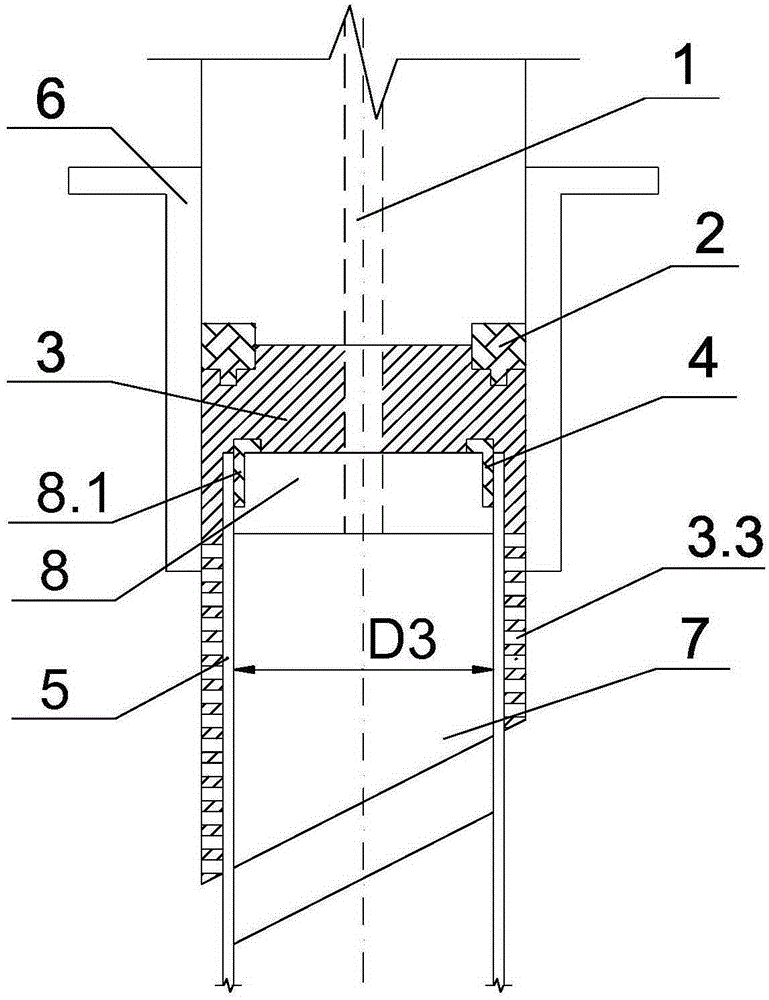

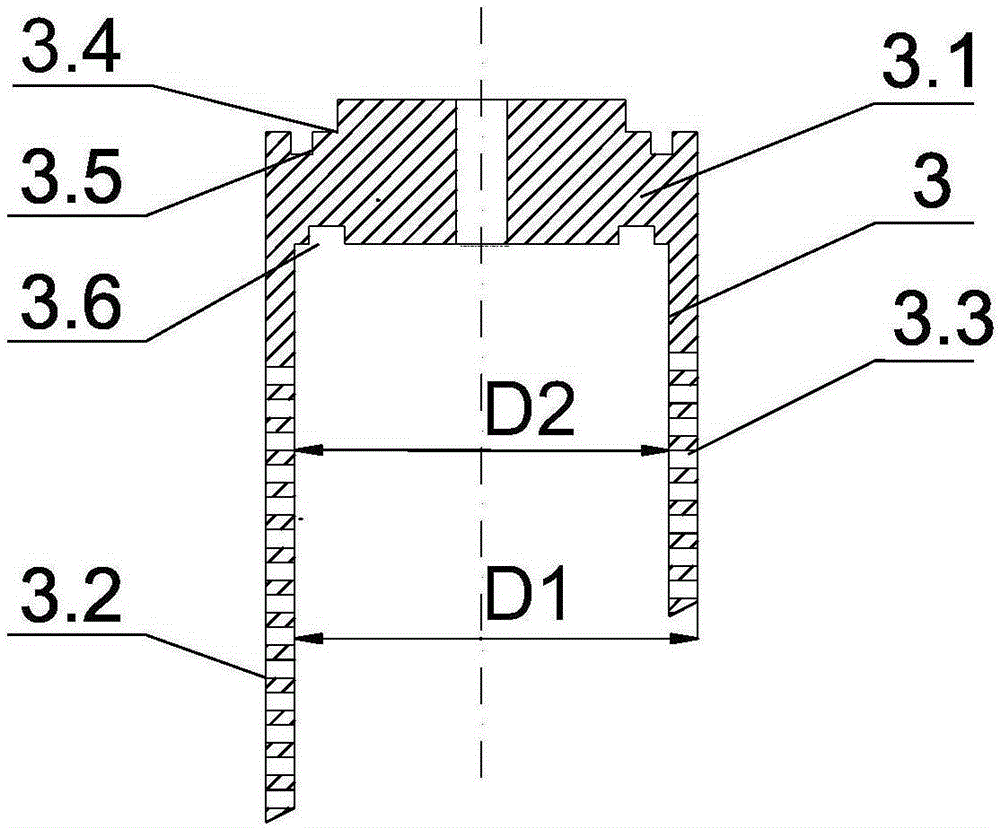

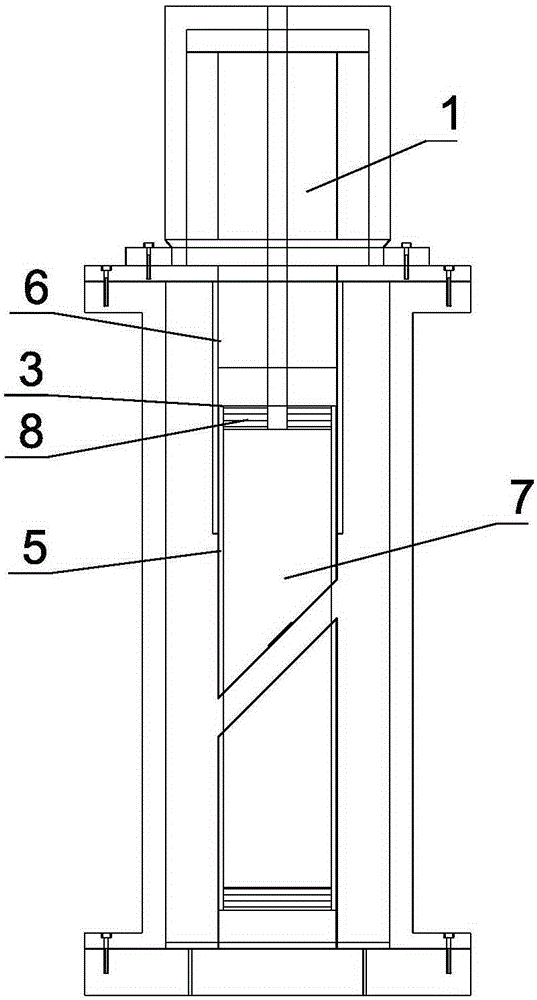

[0026] Such as figure 1 and 2 Shown is a loading mechanism that can increase the confining pressure and constrain the rotation of the sample. The loading head 3 is set in the limit cylinder 6 . The loading head 3 is in the shape of a cylindrical barrel with one end open, the side of the opening end is the side wall 3.2 of the loading head, and the other end is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com