A Blasting Test Method for Optimal Matching of Rock and Explosive

A technology of blasting test and rock, which is applied in the blasting test field of rock and explosive matching optimization, to achieve the best matching and optimization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

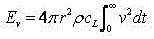

Method used

Image

Examples

Embodiment 1

[0031] The shallow hole blasting funnel test is carried out in the rock or ore area to be tested, and the standard blasting funnel test is adopted.

[0032] The rock area to be tested is granite, with a compressive strength of 68.2MPa and a density of 2.66t / m 3 , the longitudinal wave velocity is 4100m / s; three kinds of mixed emulsion explosives are selected, and the explosives and related parameters are marked according to the test sequence. Explosive 1 has a density of 1.12g / m 3 , the detonation velocity is 5200m / s; the density of explosive 2 is 1.15g / m 3 , the detonation velocity is 5300m / s; the density of explosive 3 is 1.2g / m 3 , the detonation velocity is 5450m / s.

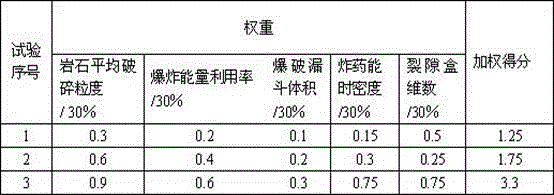

[0033]The optimal analysis steps for the matching of explosives and rocks are as follows:

[0034] 1) Conduct shallow hole blasting funnel test, choose a flat site, clean up to the bedrock surface, and the diameter of the test area is 5m. They are all vertical boreholes with a diameter of 40mm, a hole de...

Embodiment 2

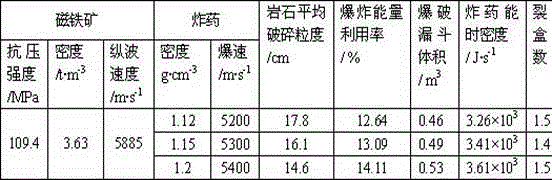

[0049] The shallow hole blasting funnel test is carried out in the rock or ore area to be tested, and the standard blasting funnel test is adopted.

[0050] The rock area to be tested is magnetite, with a compressive strength of 109.67MPa and a density of 3.63t / m 3 , the longitudinal wave velocity is 5885m / s; three kinds of mixed emulsion explosives are selected, and the explosives and related parameters are marked according to the test sequence. Explosive 1 has a density of 1.12g / m 3 , the detonation velocity is 5200m / s; the density of explosive 2 is 1.15g / m 3 , the detonation velocity is 5300m / s; the density of explosive 3 is 1.2g / m 3 , the detonation velocity is 5450m / s.

[0051] The optimal analysis steps for the matching of explosives and rocks are as follows:

[0052] 1) Conduct shallow hole blasting funnel test, choose a flat site, clean up to the bedrock surface, and the diameter of the test area is 5m. They are all vertical boreholes with a diameter of 40mm, a ho...

Embodiment 3

[0067] The shallow hole blasting funnel test is carried out in the rock or ore area to be tested, and the standard blasting funnel test is adopted.

[0068] The rock area to be tested is magnetite, with a compressive strength of 109.67MPa and a density of 3.63t / m 3 , the longitudinal wave velocity is 5885m / s; three kinds of mixed emulsion explosives and two kinds of mixed ammonium oil explosives are selected, and the explosives and related parameters are marked according to the test sequence. Explosive 1 has a density of 1.12g / m 3 , the detonation velocity is 5200m / s; the density of explosive 2 is 1.15g / m 3 , the detonation velocity is 5300m / s; the density of explosive 3 is 1.2g / m 3 , the detonation velocity is 5450m / s; the density of explosive 4 is 1.0g / m 3 , the detonation velocity is 3200m / s; the density of explosive 5 is 0.9g / m 3 , the detonation velocity is 3100m / s.

[0069] The optimal analysis steps for the matching of explosives and rocks are as follows:

[0070]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| P-wave velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com