Control method of commodity transmission control system of vending machine

A technology of transmission control and control method, which is applied in the direction of coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc., which can solve the problem of beverage storage time Problems such as deterioration, cargo damage, and cargo jamming are achieved to ensure accuracy and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

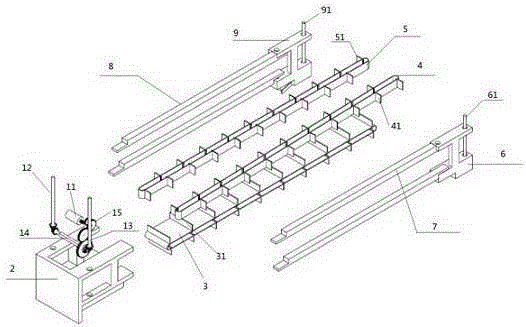

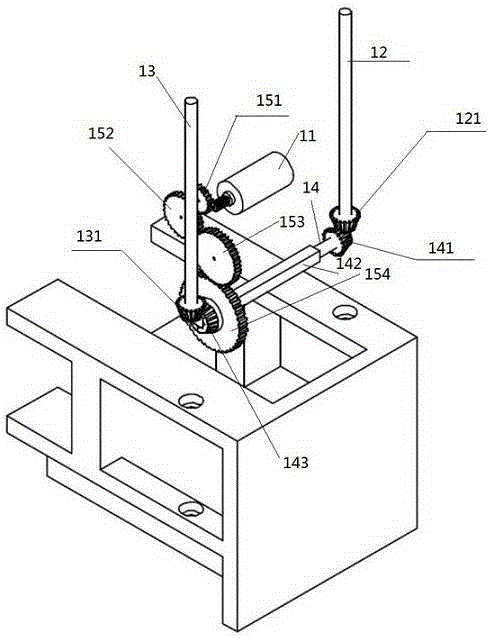

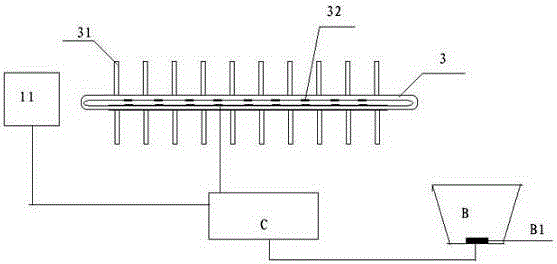

[0030] Combine below Figure 1 to Figure 3 , the present invention is further described:

[0031] Such as figure 1 and figure 2 As shown, a goods transmission control system for an automatic vending machine includes a transmission mechanism, a first conveyor belt 4, a second conveyor belt 5 and a supporting conveyor belt 3. Commodities are placed on the supporting conveyor belt 3, and the first conveyor belt 4 and the second conveyor belt The two conveyor belts 5 are respectively located on both sides of the commodity to protect the commodity from falling out of the supporting conveyor belt 3, the first conveyor belt 4, the second conveyor belt 5 and the supporting conveyor belt 3 are arranged in parallel, and their common end is provided with the transmission mechanism Drive them to rotate, and the common other end is the export port to output the goods.

[0032] A plurality of clips 31, 41, 51 are respectively provided on the first conveyor belt 4, the second conveyor be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com