Nuclear fuel component repair monitoring system

A nuclear fuel assembly and monitoring system technology, applied in the field of nuclear power generation, can solve the problems of affecting repair efficiency, nuclear fuel assembly 500 damage, high error probability, etc., and achieve good safety, high repair efficiency, and good operation safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

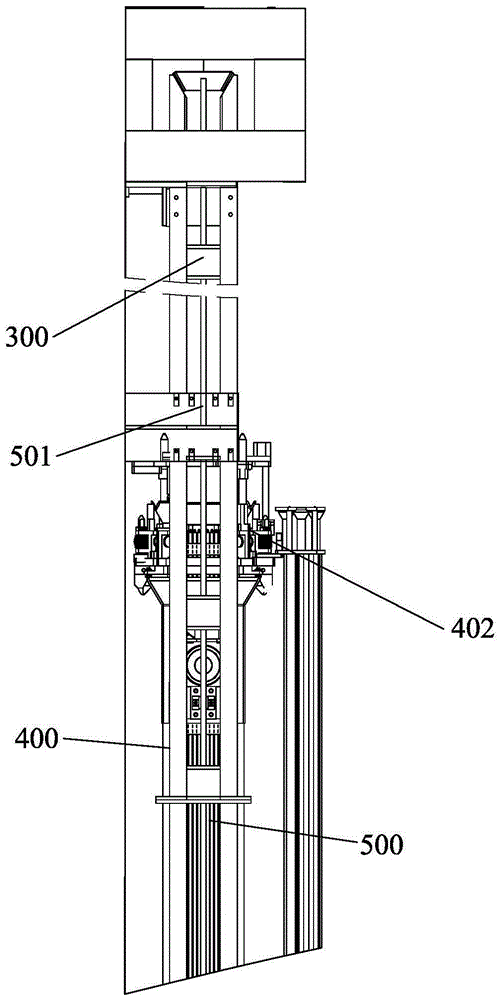

[0025] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

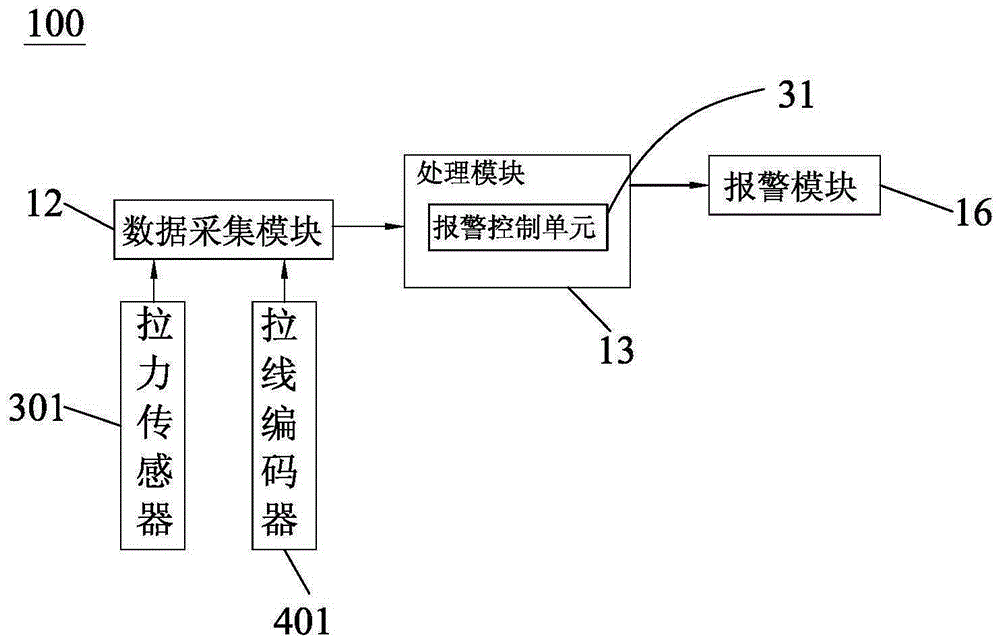

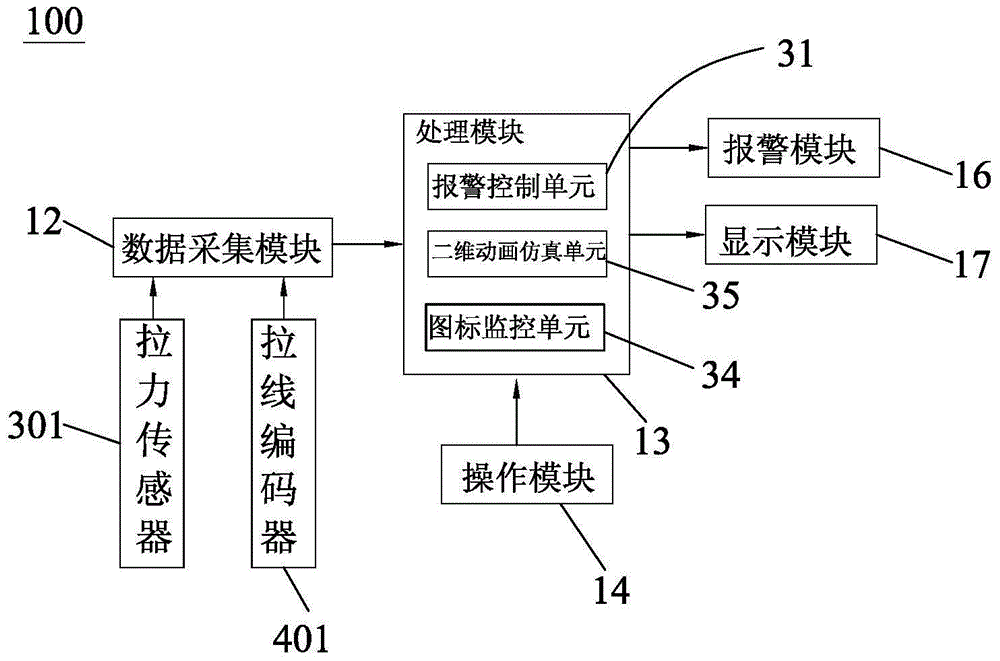

[0026] refer to Figure 1a, the present invention provides a nuclear fuel assembly repair monitoring system 100, which is used for monitoring during the replacement of nuclear fuel rods, including a data acquisition module 12, a processing module 13 and an alarm module 1, and the data acquisition module 12 is connected with a tension sensor 301 ( Installed on the nuclear fuel rod drawing and inserting tool 300) is connected with the wire encoder 401 (installed on the new fuel elevator 400), acquires and processes the tension data of the tension sensor 301 and the height data of the wire encoder 401; the processing module 13 includes an alarm control unit 31, the alarm control unit 31 judges whether the tension data exceeds a preset tension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com