Device and method for cleaning and classifying nuts

A sorting device and a sorting method technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of reduced assembly production efficiency, time and energy consumption, unfavorable promotion and use, etc., and achieve improvement Efficiency, reduction of manpower and material resources, and improvement of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

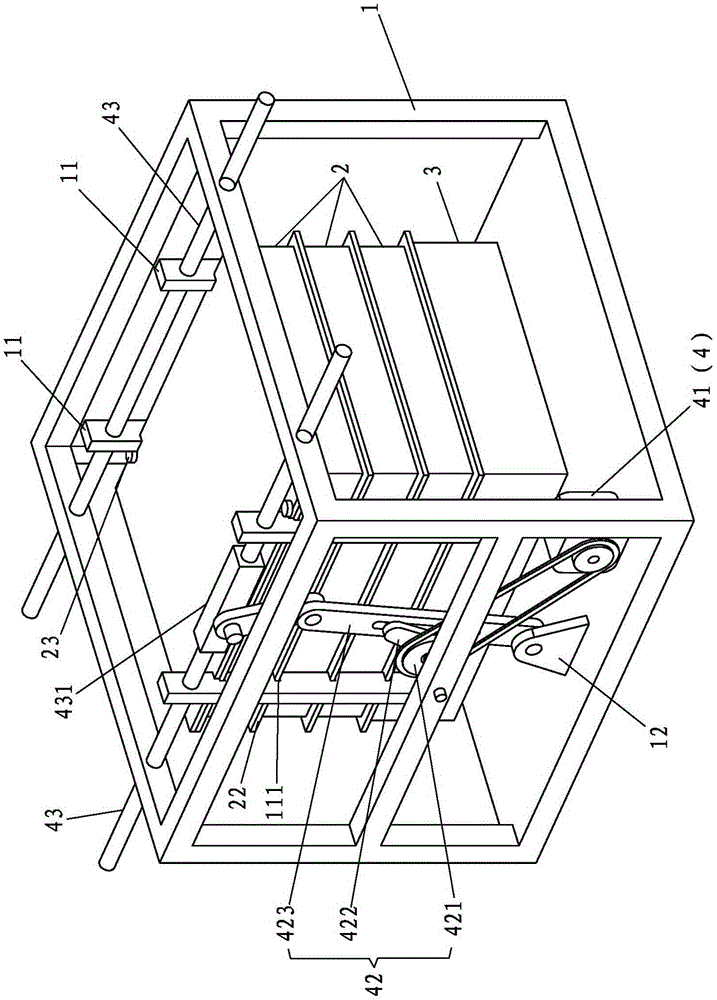

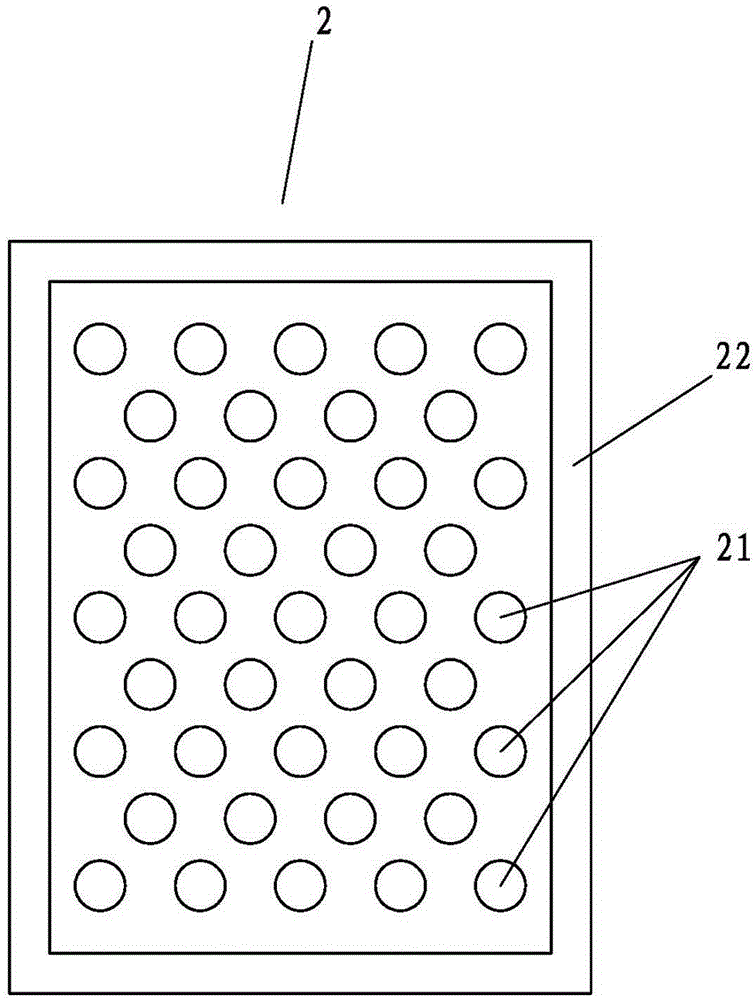

[0035] The invention relates to a nut cleaning and sorting device, such as figure 1 As shown, it mainly includes a base 1, a sorting box 2 and a filter bucket 3. The sorting box 2 and the filter bucket 3 are set up and down and suspended on the base 1. The base 1 is provided with a vibrating mechanism 4. The vibrating mechanism 4 connects the sorting box 2 and the filter bucket 3 via a bracket 11 to drive the sorting box 2 and the filter bucket 3. The filter hopper 3 vibrates.

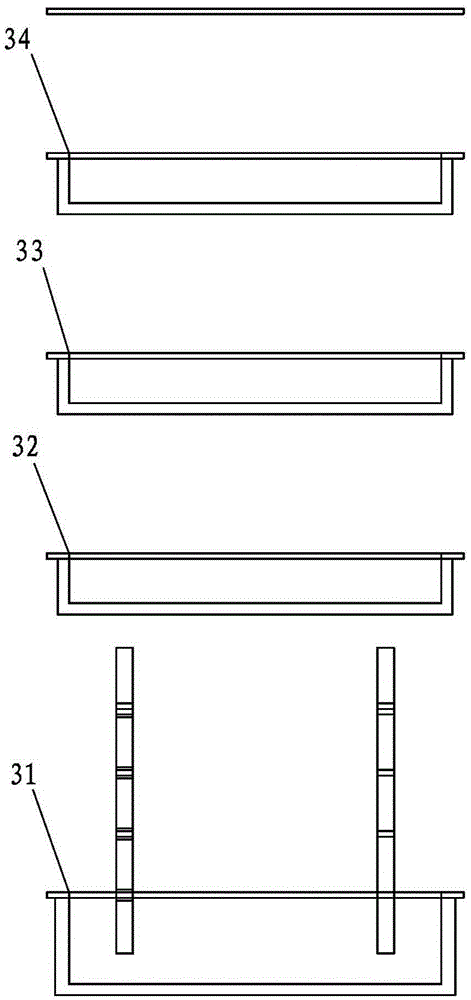

[0036] Filter hopper 3 comprises filter hopper box 31 and is located at the filter screen in filter hopper box 31, and this filter screen preferably adopts double filter screen form; Concrete preferred embodiment is for example figure 2 As shown, the filter bucket 3 includes a filter bucket box 31, a liquid storage layer 32, a fine-pore filter screen 33 and a la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com