Vacuum suction wall-climbing robot and using method thereof

A wall-climbing robot and vacuum adsorption technology, which is applied in the field of wall-climbing robots, can solve problems such as low efficiency, long cycle time, and poor safety, and achieve the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

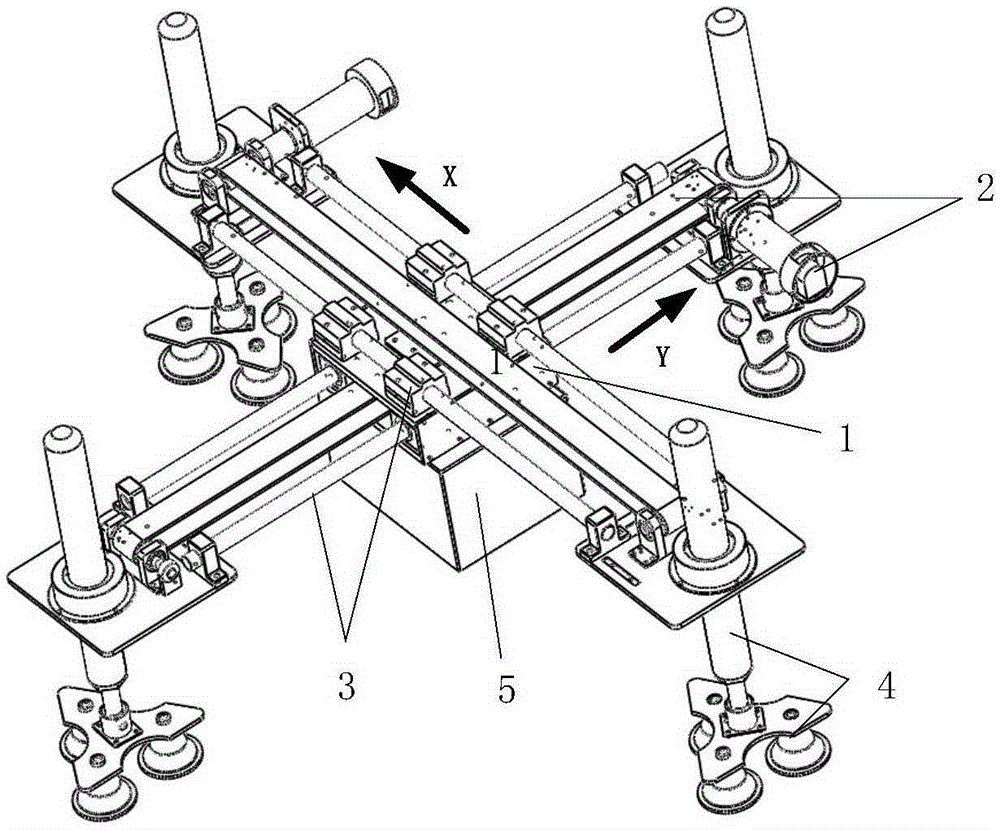

[0028] Embodiment 1: see attached figure 1 , a vacuum adsorption wall-climbing robot, which includes: a box body 1, a transmission mechanism 2, a guide mechanism 3, an adsorption mechanism 4 and a detection radar 5;

[0029] The box body 1 is divided into upper and lower layers;

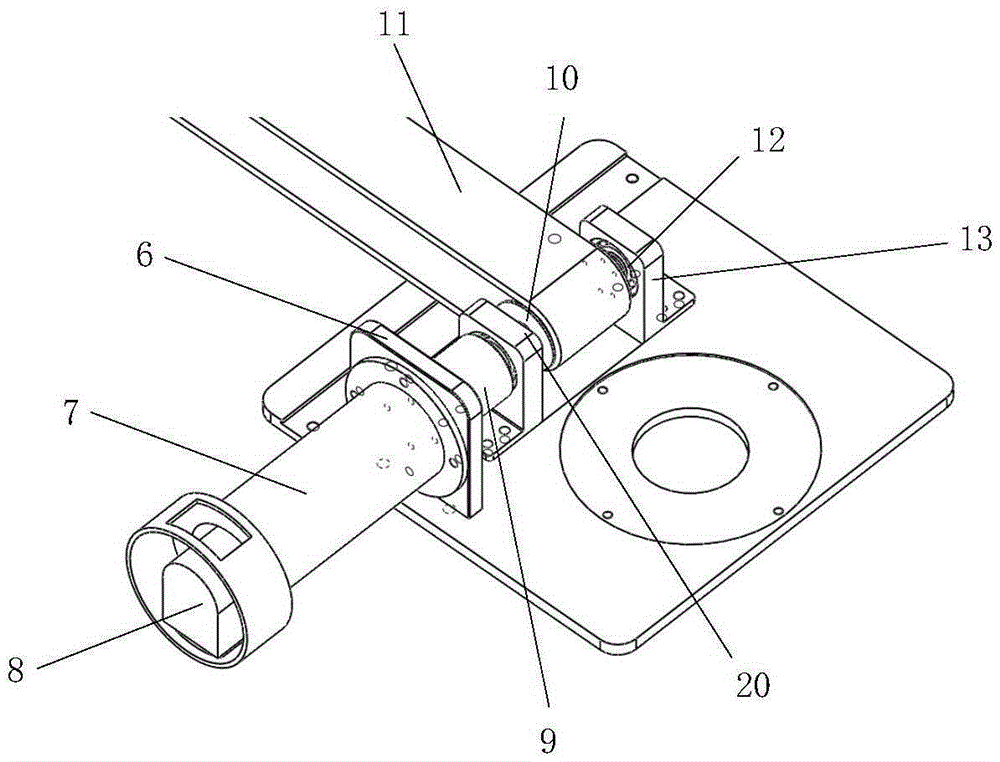

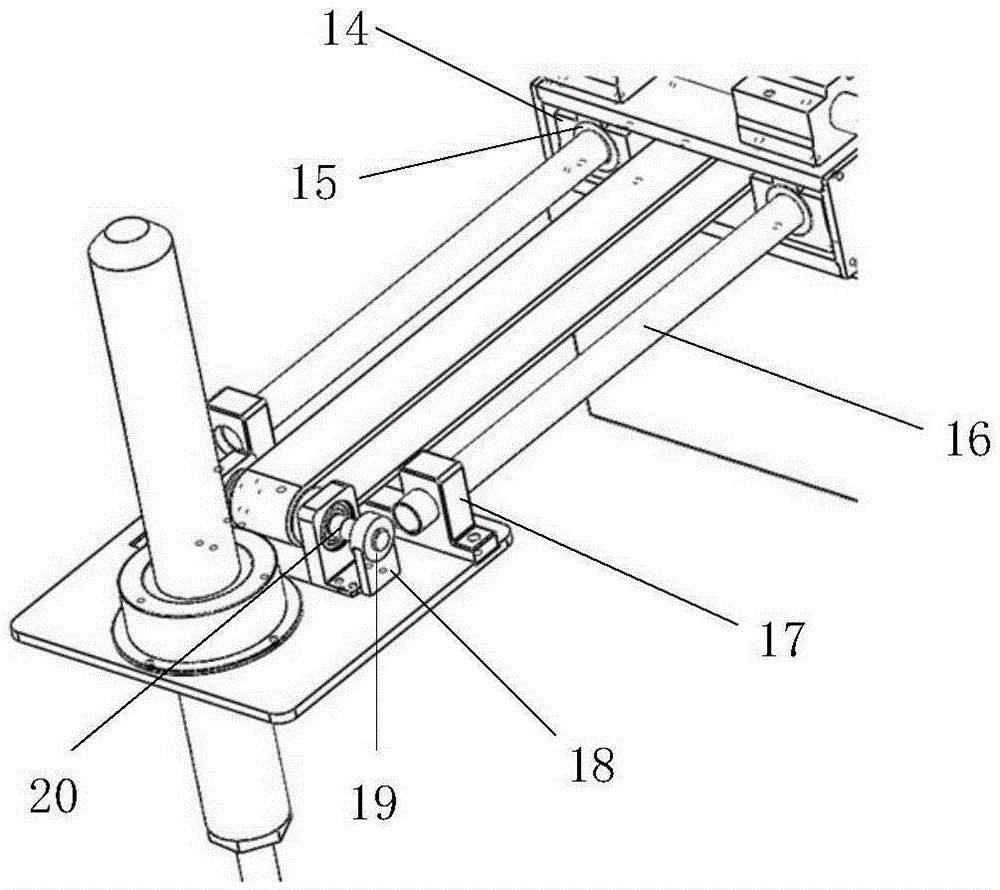

[0030] The transmission mechanism 2 is divided into two sets of synchronous belts 11 crossing in a cross shape, and each set of synchronous belts 11 is driven by the motor 8; the two sets of synchronous belts 11 are respectively installed on the upper and lower layers of the box body 1;

[0031] The guide mechanism 3 cooperates with the timing belt 11 in the transmission mechanism 2, and is also installed on the upper and lower layers of the box body 1;

[0032] The adsorption mechanism 4 is installed at both ends of each group of synchronous belts 11 , including: an electric push rod 21 and a suction cup group 25 below the electric push rod 21 , and the suction cup group 25 is controlled by a solen...

Embodiment 2

[0037] Embodiment 2: the use method of vacuum adsorption wall climbing robot, it is based on the vacuum adsorption wall climbing robot that is used for tunnel wall lining detection as described in embodiment 1, and its use method is as follows:

[0038] Step 1, the state of the robot is initialized, and one of the timing belts 11 is defined as the x guide rail, and the other is the y guide rail;

[0039] Step 2, make the expansion and contraction of the electric push rod 21 in the adsorption mechanism 4 be in a proper position, so that the suction cups of the suction cup groups 25 at the ends of the x and y guide rails are attached to the wall and are all in the adsorption state;

[0040] Step 3, the suction cup of the y-rail is released, and the vacuum pressure switch is detected to detect the vacuum degree in the suction cup. When the vacuum degree is less than a certain threshold, the suction cup of the y-rail is lifted to make the y-rail turn into a moving state;

[0041] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com