A kind of high-performance nickel-based superalloy and its manufacturing method

A nickel-based superalloy and a manufacturing method technology, which are applied in the field of high-performance nickel-based superalloy and its manufacture, and the field of high-performance nickel-based superalloy, can solve the problem of difficult deformation of casting superalloy, and achieve good mechanical properties, excellent quality, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

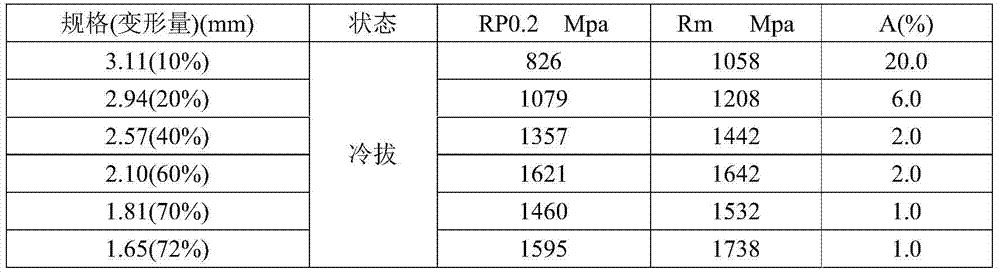

[0017] A kind of high performance nickel base superalloy, its chemical composition (wt%) is as shown in table 1:

[0018] The chemical composition (wt%) of alloy in the embodiment 1 of table 1

[0019] Al

Cr

Mo

Nb

Ti

C

Si

mn

B

Zr

Fe

Cu

Ni

2.31

11.31

3.82

1.73

0.50

0.064

0.13

0.18

0.013

0.07

0.21

<0.10

Remain

[0020] The concrete steps and process parameters of its manufacturing method are as follows:

[0021] 1. Melting: Weigh the raw materials of each component and put them into the crucible, among them, Cr: 11.31%, Mo: 3.82%, Nb: 1.73%, Ni: the balance; in a high vacuum state, the melting temperature of the melting furnace is set to 1530°C, after the raw materials are completely melted, continue heating for 5 minutes until the raw materials are melted.

[0022] 2. Refining: Control the temperature of the above solution at 1560-1580°C, and fill the furnace with argon until th...

Embodiment 2

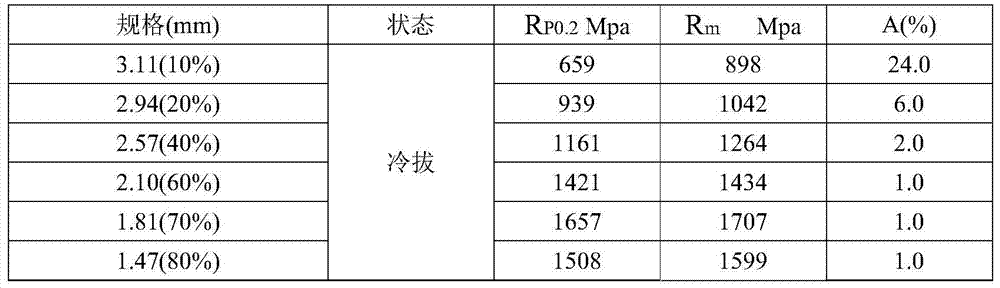

[0031] A kind of high performance nickel base superalloy, its chemical composition (wt%) is as shown in table 3:

[0032] The chemical composition (wt%) of alloy in the embodiment 2 of table 3

[0033] Al

Cr

Mo

Nb

Ti

C

Si

mn

B

Zr

Fe

Cu

Ni

1.92

11.39

2.98

1.08

0.40

0.047

0.13

0.13

0.014

0.07

0.11

<0.10

Remain

[0034] The concrete steps and process parameters of its manufacturing method are as follows:

[0035] 1. Melting: Weigh the raw materials of each component and put them into the crucible, wherein, Cr: 11.39%, Mo: 2.98%, Nb: 1.08%, Ni: the balance; in a high vacuum state, the melting temperature of the melting furnace is 1530°C, after the raw materials are completely melted, continue heating for 5 minutes until the raw materials are melted.

[0036] 2. Refining: Control the temperature of the above solution at 1560-1580°C, and fill the furnace with argon until the vacuum d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com