Whey food processed from cereals harvested at grain filling later stage at high-quality air, kept fresh at high-quality air and eaten at high-quality air

A grain and food technology, applied in the field of fresh and live grain whey and its production, can solve the problems of troublesome manufacturing, large quality deterioration and loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

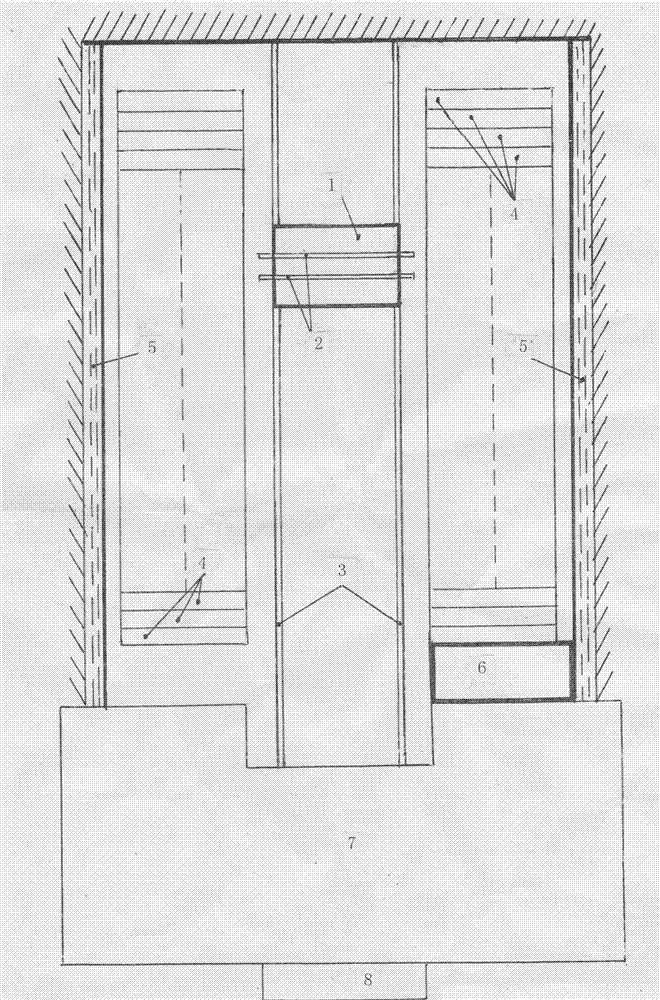

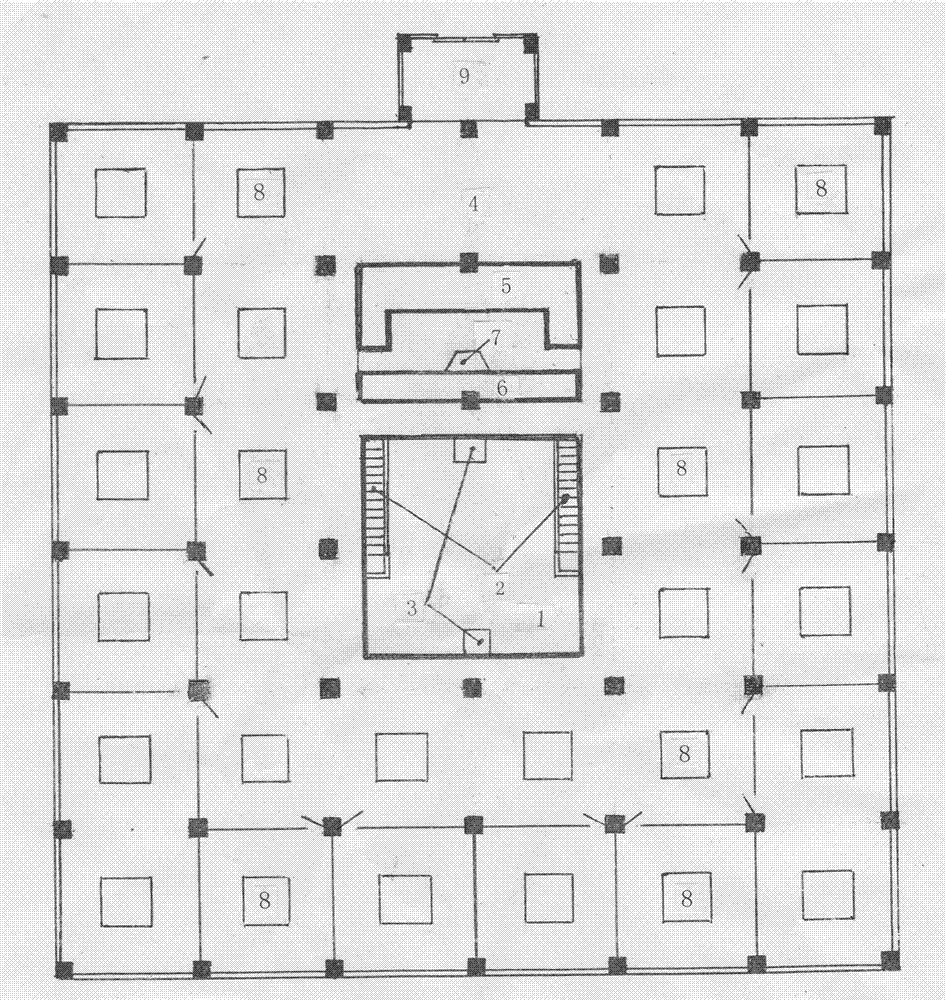

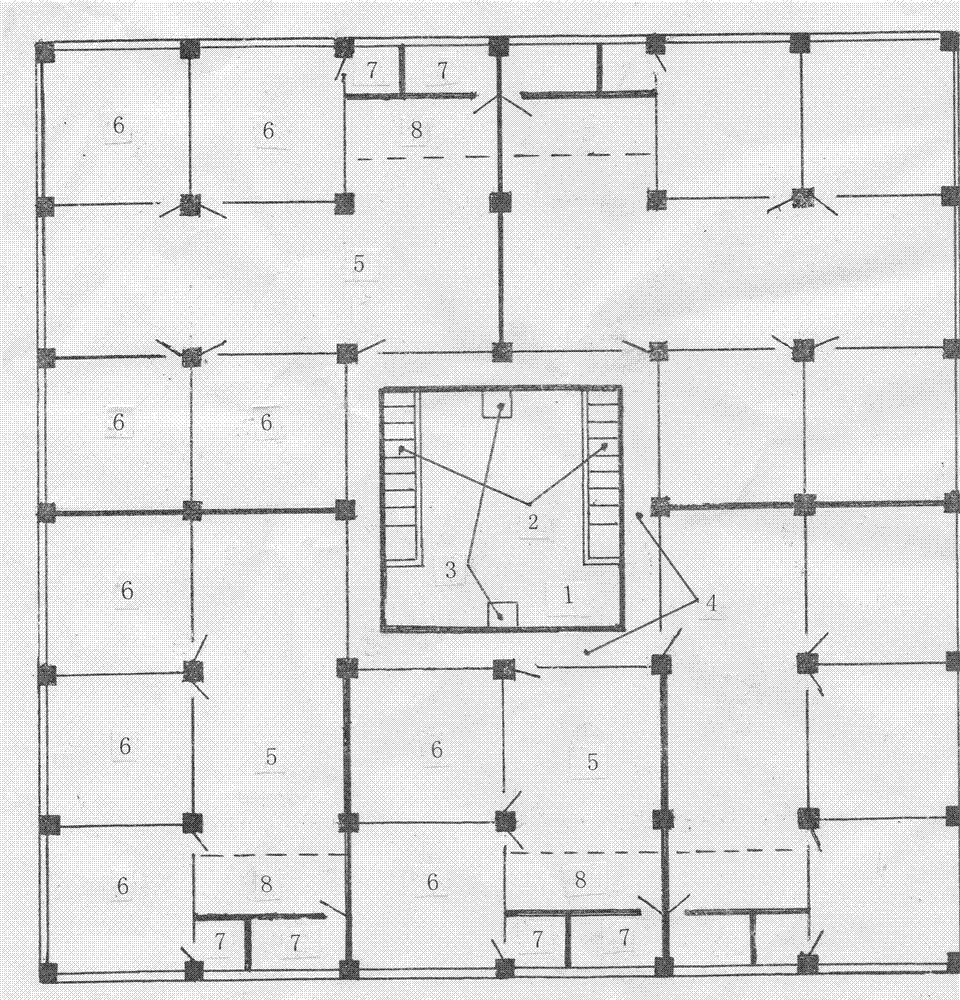

[0018] figure 1 It is an embodiment of the technical scheme 5 "only use the ground temperature water molecule atomization modified atmosphere fresh-keeping storehouse of natural resources". The basement is 10m deep, 24m wide, and 70m long, with a total warehouse volume of 2,500 cubic meters. Each piece of goods is 1M×1M×1M and placed in a standard pallet made of engineering plastic profiles. Figure 1 is the rail car for the transfer of goods entering and leaving the warehouse. When the car arrives at the door of the warehouse, the crane lifts the shelf and puts it on the track for entering and leaving the warehouse. Return to the original position of the shelf on the transfer rail car. There is a baffle at the end of the shelf track to prevent the shelf from moving, and a movable track is set at the entrance and exit port. After the shelf is put in, the movable track is erected to lock the shelf. When the shelf is transported out, the movable track will be decoupled from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com