Steel skeleton composite pipe

A technology of composite pipe and steel frame, which is applied to pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problem of drainage culvert corrosion and other problems, and achieve the effect of easy installation and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

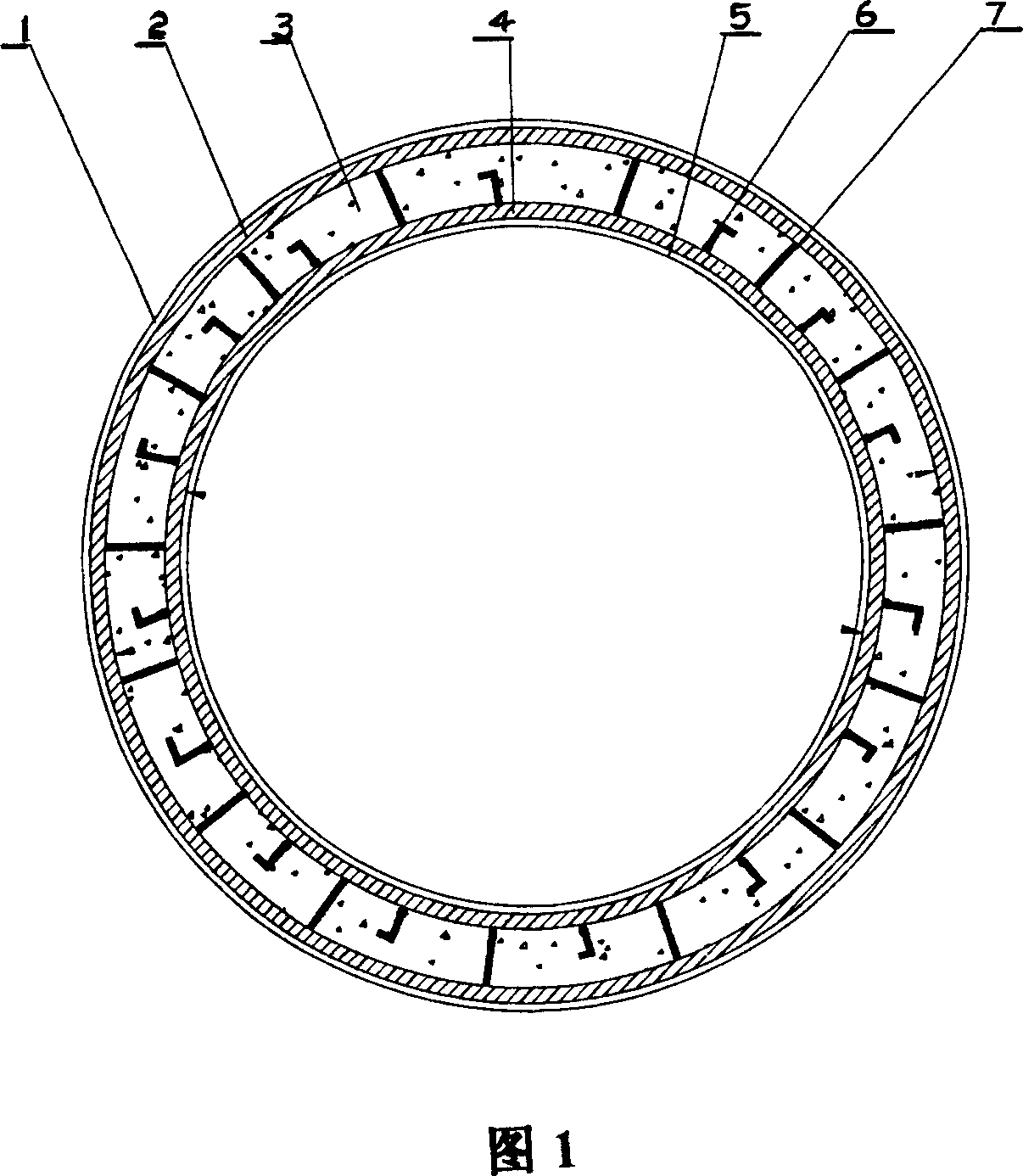

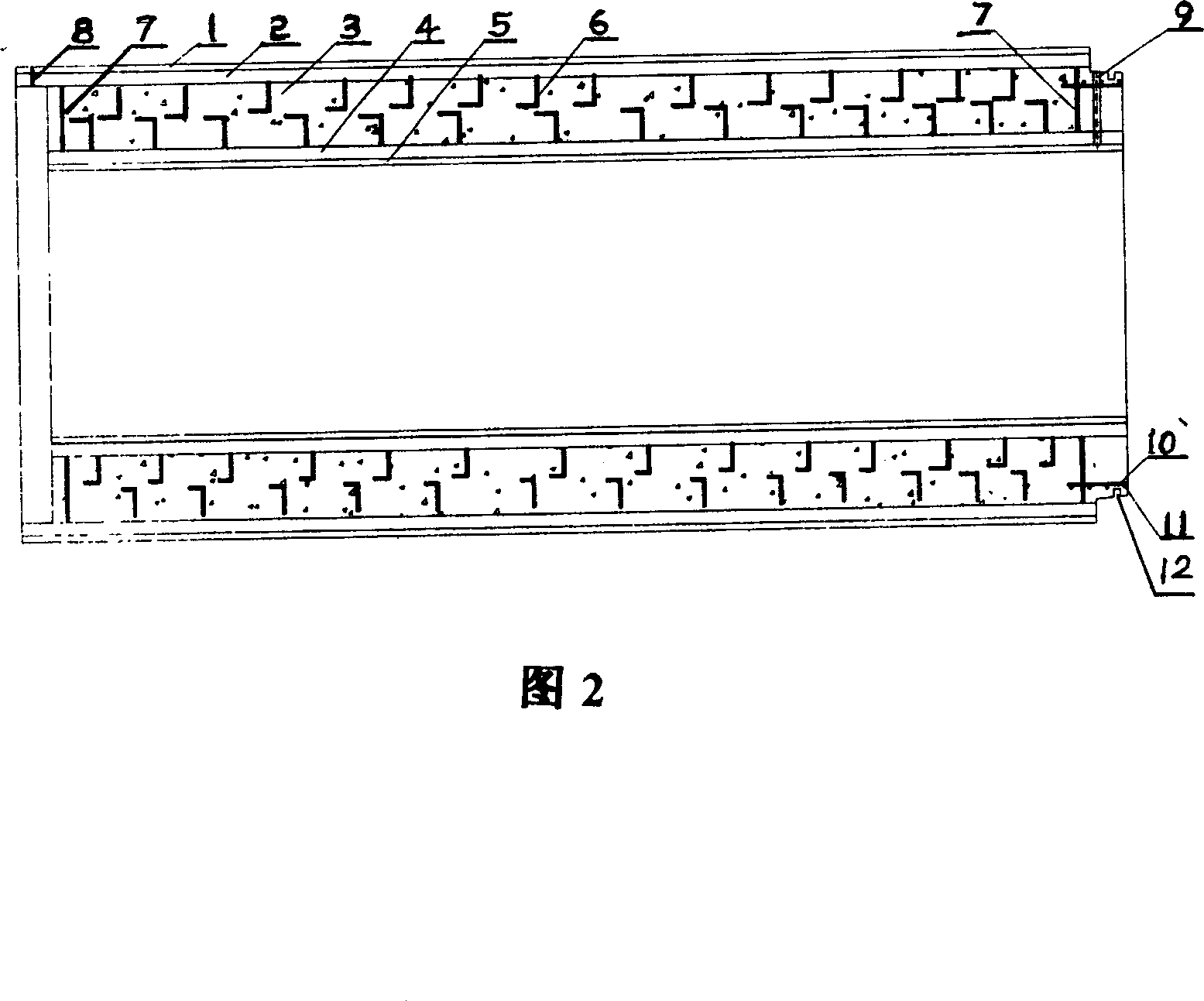

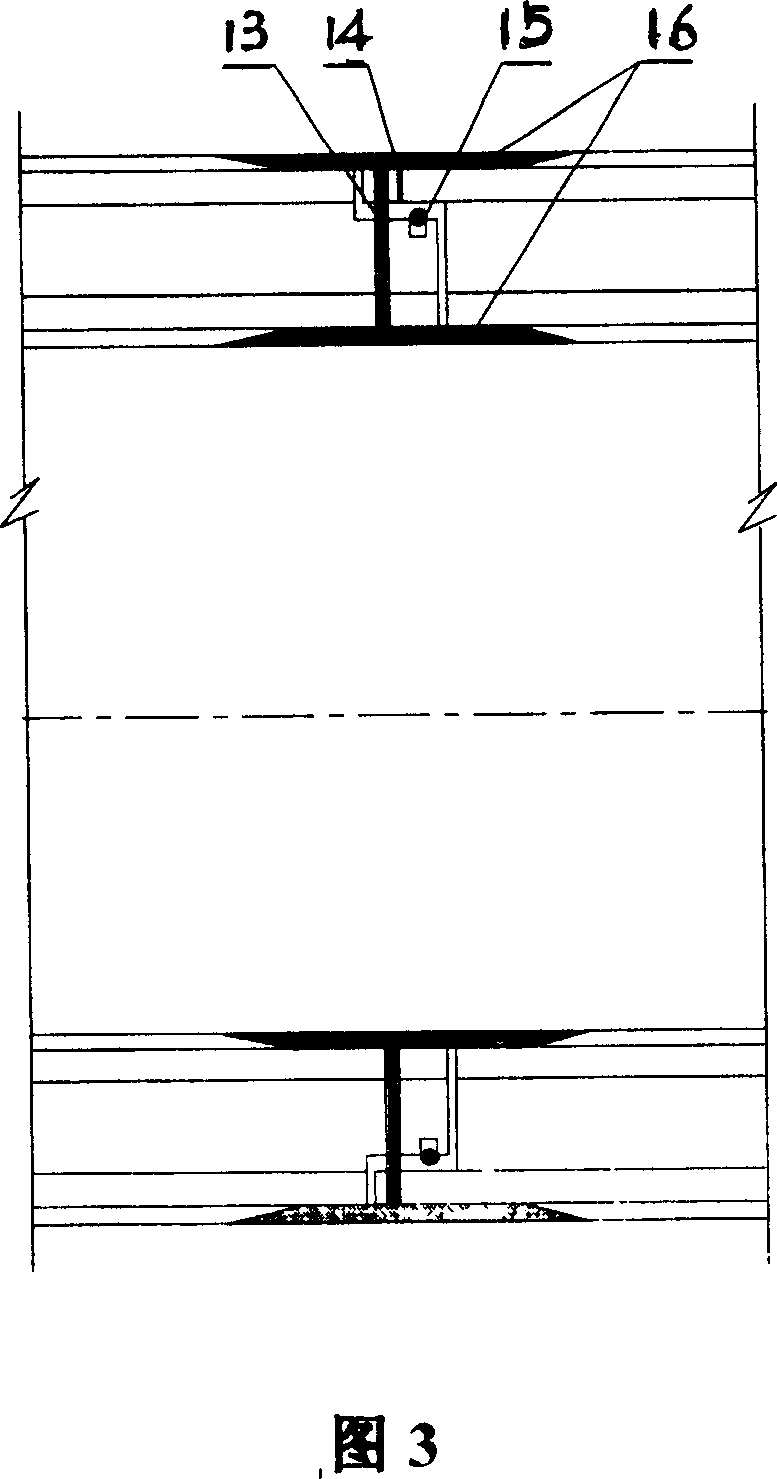

[0017] As shown in Figure 1, the main body of the steel-reinforced composite pipe is composed of an outer steel lining 2, a concrete filling layer 3, and an inner steel lining 4. This structure has not only brought into play the high strength and ductility of the steel of the inner and outer steel linings, but also the rigidity of the cheap concrete, and the structural form is similar to a "sandwich". Therefore, this structural form can guarantee The steel-reinforced composite pipe works normally under the working conditions of buried depth of more than 60m and no internal pressure. In order to ensure the overall coordinated work of the product of the present invention and prevent local stability damage, certain "L", "T", "P" and other nail-shaped anchor bars 6 are arranged on the outer wall of the inner steel lining and the inner wall of the outer steel lining, and can also be used separately Arrange some "L", "T", "P" and other nail-shaped anchor bars 6 on the outer wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com