Sealing bearing

A technology of sealed bearings and bearings, which is applied to transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problems of bearings and gears not being cooled and lubricated, reducing the service life of equipment, and the production efficiency of video crude oil, etc., to achieve Reduce the oil pressure, reduce the oil intake, and improve the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described below in conjunction with accompanying drawing.

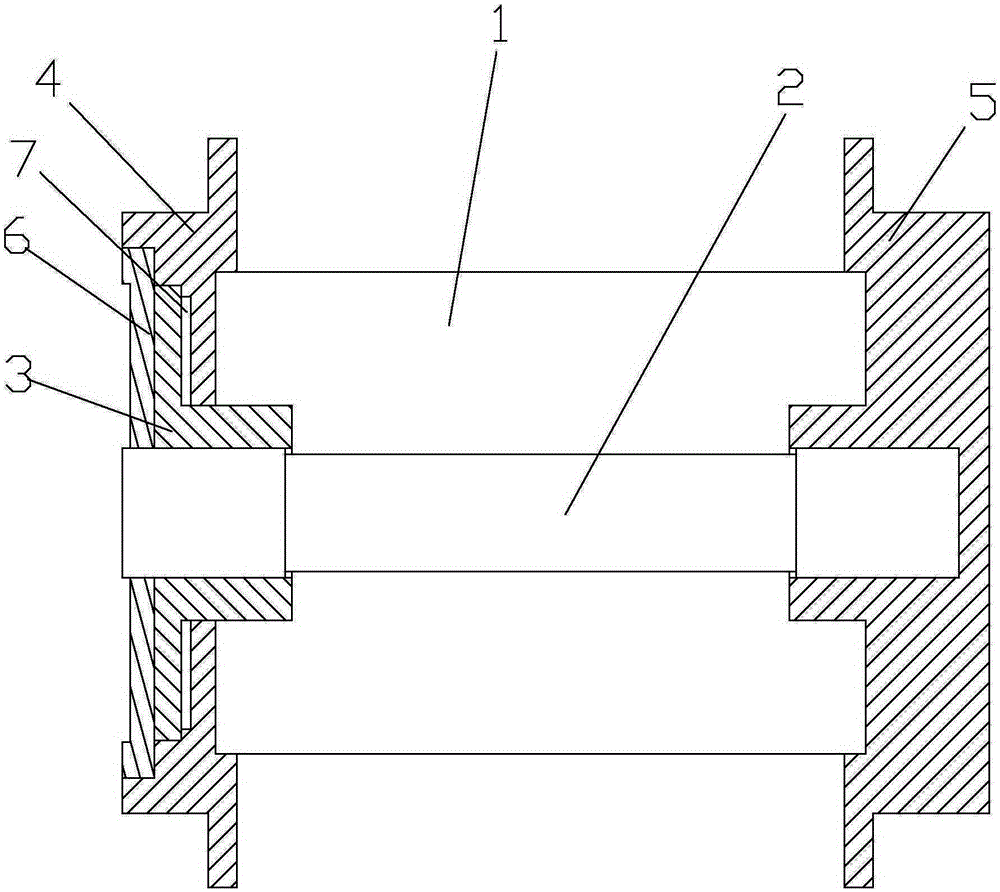

[0013] attached figure 1 It is a sealed bearing according to the present invention, comprising a bearing housing 1, a transmission shaft 2, a bearing 3, a bearing cover 4, and a sealing cover 5; the transmission shaft 2 is installed inside the bearing housing 1, and one end is fixed on the bearing 3, The other end is installed in the sealing cover 5; the sealing cover 5 is fixedly installed at one end of the bearing housing 1; the bearing 3 fixes the transmission shaft 2 and is installed in the bearing cover 4; A seal ring 5; an oil guide groove 7 is provided between the bearing cover 4 and the bearing 3; the seal cover 5 and the seal ring 6 are both made of wear-resistant materials.

[0014] The solution of the present invention installs the transmission shaft 2 inside the bearing box 1, one end is fixed on the bearing 3, and the other end is installed in the sealing cover 5, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com