Experiment clamp with an angle adjusting function and a height adjusting function

A technology of height adjustment and angle adjustment, which is applied in angle/taper measurement, mechanical thickness measurement, etc., can solve problems such as unguaranteed accuracy, difficult position adjustment, labor-intensive efficiency, etc., to achieve low cost, improve test accuracy, save effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

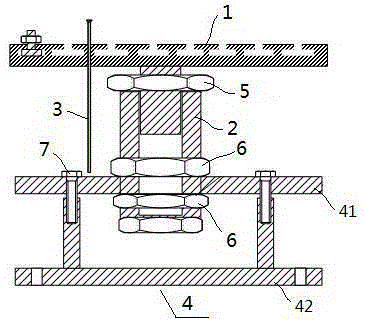

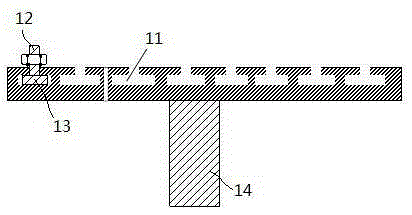

[0037] Below in conjunction with accompanying drawing, the present invention will be further described:

[0038] Figure 1 to Figure 9An experimental fixture with angle adjustment function and height adjustment function is shown, including a square plate 1 , a hollow bolt 2 , an angle pointer 3 , a fastening nut and a fixture body 4 . The square disc 1 is connected with the fixture main body 4 through the hollow bolt 2, and the square disc 1, the hollow bolt 2 and the fixture main body 4 can all rotate relative to each other. Angle and height relative to clamp body 4. The angle pointer 3 is arranged on the square disk 1 , and the angle scale is arranged on the fixture main body 4 to cooperate with the angle pointer 3 to display the angle through which the square disk 1 turns. The angle pointer 3 is also provided with a height scale line 31 . The structure of the hollow bolt 2 is as follows Figure 5 As shown, the outer cylindrical surface of the hollow bolt 2 is processed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com