An experimental device for elastohydrodynamic lubrication of hydraulic cylinders under variable load conditions

An experimental device, hydraulic cylinder technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problem of not being able to simulate the working environment of hydraulic cylinders realistically, and achieve the effect of enhancing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below with reference to the accompanying drawings.

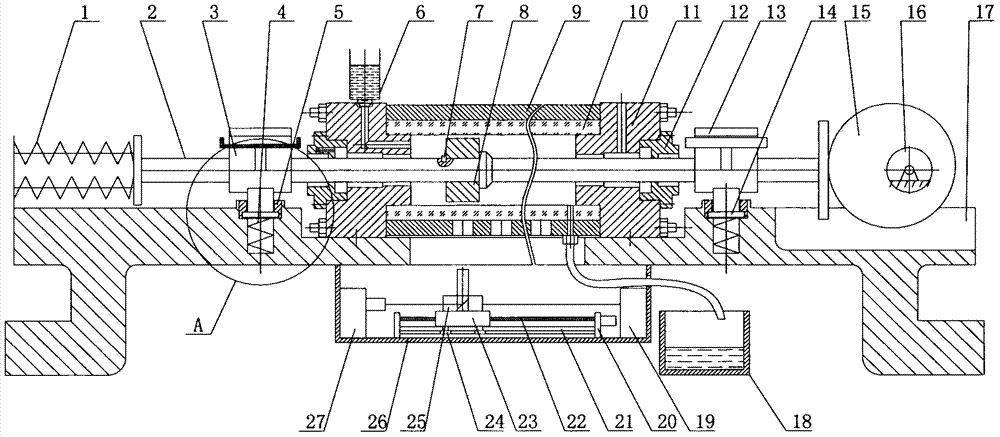

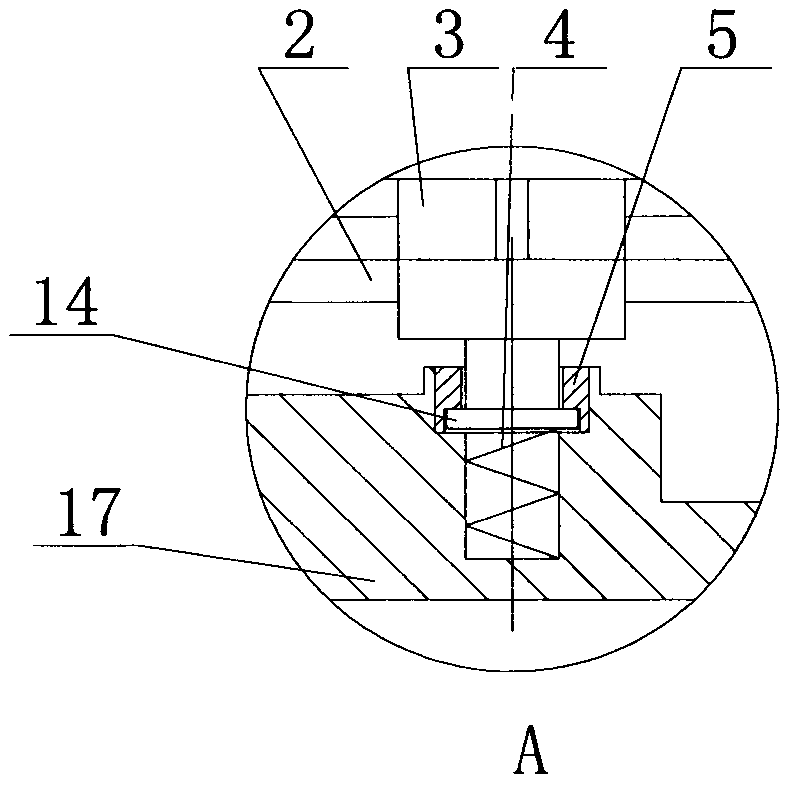

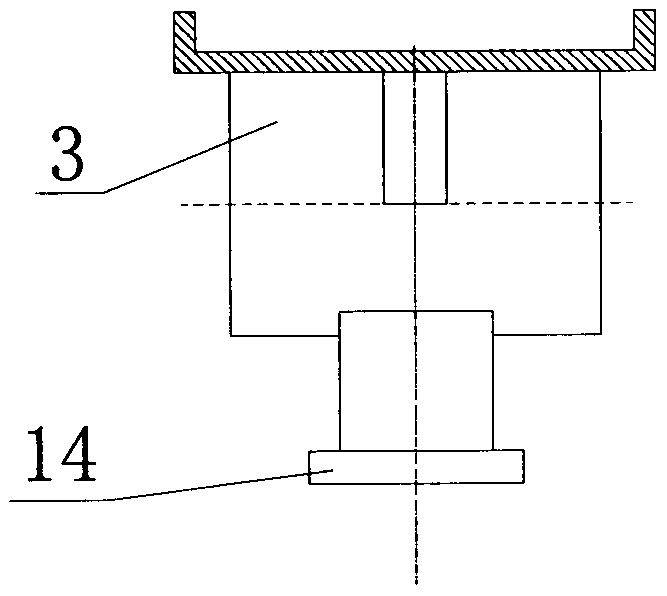

[0040] like Figure 1-12 As shown, the present invention includes a base 17, a cylinder assembly, a driving device, a measuring device and a lubricating device. The cylinder assembly includes a spring 1, a piston rod 2, a key 7, a piston 8, an outer cylinder 9, a glass lining The sleeve 10, the end cover 11 and the guide sleeve 12, the left end of the plug rod 2 is connected to the spring 1 fixed on the base 17 through the linear bearing 3 on the left side, and the other end passes through the linear bearing 3 under the action of the spring 1. In contact with the cam 15, one end of the spring 1 is fixed on the spring seat on the frame, and the other end passes through the guide post on the left end of the piston rod 2, the piston 8 is connected with the piston rod 2 through the key 7, and the piston rod 2 passes through the guide. The sleeve 12, the guide sleeve 12 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com