Magnetic inductive type rebound sensor

A magnetic induction and sensor technology, applied in the direction of testing the hardness of materials, can solve the problems of different maintenance cycles, induction failure, photoelectric tube dust, oil sensitivity, etc., and achieve the effect of long service life and accurate testing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

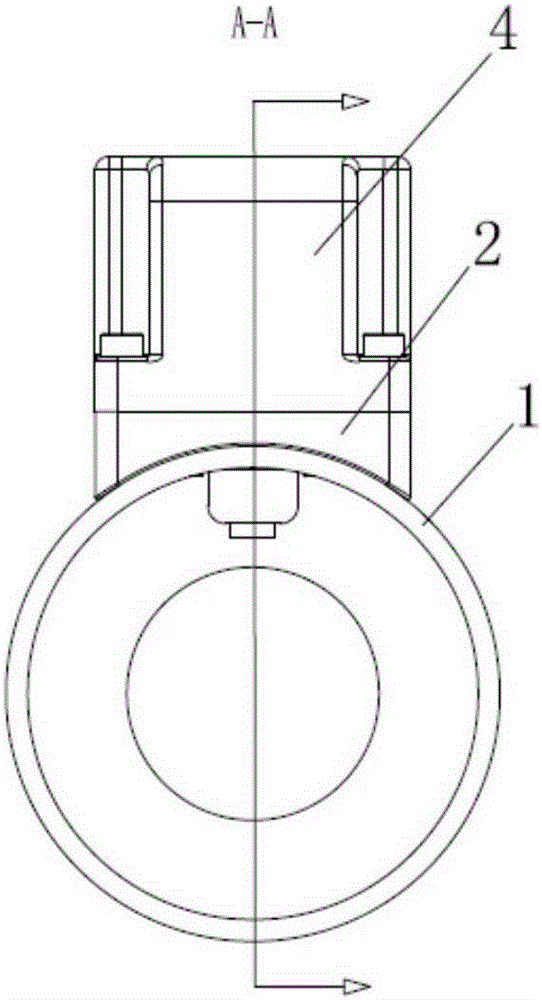

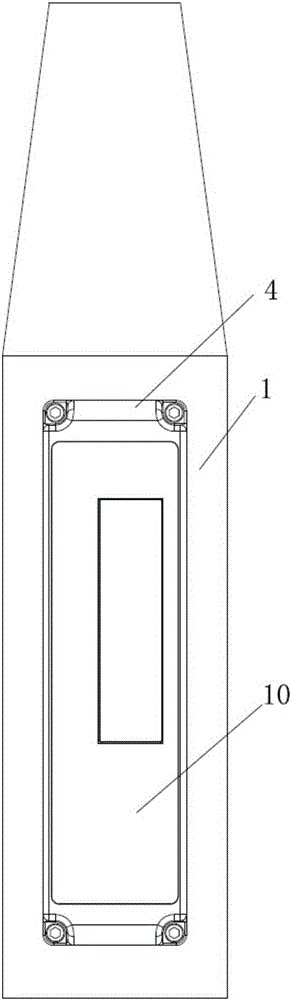

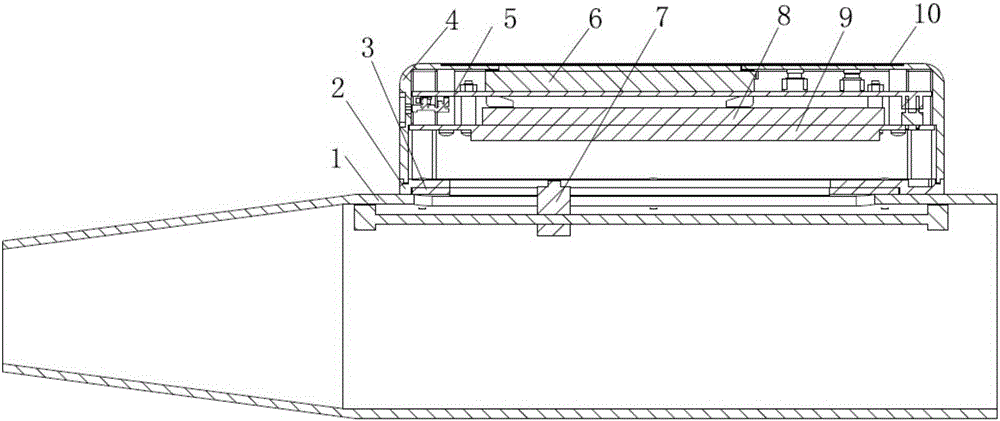

[0021] Such as Figure 1-3 Shown in detail, the present invention provides a magnetic induction rebound sensor, including a housing 1 with an upper housing 4 and a lower housing 2, the top surface of the upper housing 4 is provided with a display connected to the main board 5 screen 6, the main board 5 is provided with a control circuit and an acquisition circuit, the display screen 6 is provided with a film 10, the lower housing 2 is provided with a base 3 connected to the upper housing 4, and the base 3 is provided with There is a slider 7 capable of reciprocating movement, the slider 7 is connected with the hammer, the upper housing 4 is provided with a power supply 8, the power supply 8 is connected to the magnetic induction device, preferably the power supply 8 is a battery, and the magnetic induction The device includes a Hall sensor fixed on the slider 7, a magnetic strip 9 is arranged directly above the Hall sensor, and the slider 7 is preferably provided with a pointe...

Embodiment 2

[0024] Such as figure 1 , 2 As shown in and 4, the present invention provides a magnetic induction rebound sensor, including a housing 1 provided with an upper housing 4 and a lower housing 2, the top surface of the upper housing 4 is provided with a display connected to the main board 5 screen 6, the main board 5 is provided with a control circuit, the display screen 6 is provided with a film 10, the lower case 2 is provided with a base 3 connected to the upper case 4, and the base 3 is provided with a Moving slider 7, the upper housing 4 is provided with a power supply 8, the power supply 8 is connected to a magnetic induction device, and the magnetic induction device includes a miniature magnetic block fixed on the slider 7, and the miniature magnetic block A magnetic induction circuit 11 including several Hall sensors is arranged directly above, and the several Hall sensors are arranged in a matrix, preferably a linear array. In this embodiment, the miniature magnetic bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com