Pipeline elbow detection method based on remote field eddy current and detection device

A technology for pipe elbows and far-field eddy currents, applied in the direction of material magnetic variables, etc., can solve problems such as pipe elbow defects, pipe elbow detection, etc., achieve the same sensitivity, easy defect resolution, and reduce detection blind spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

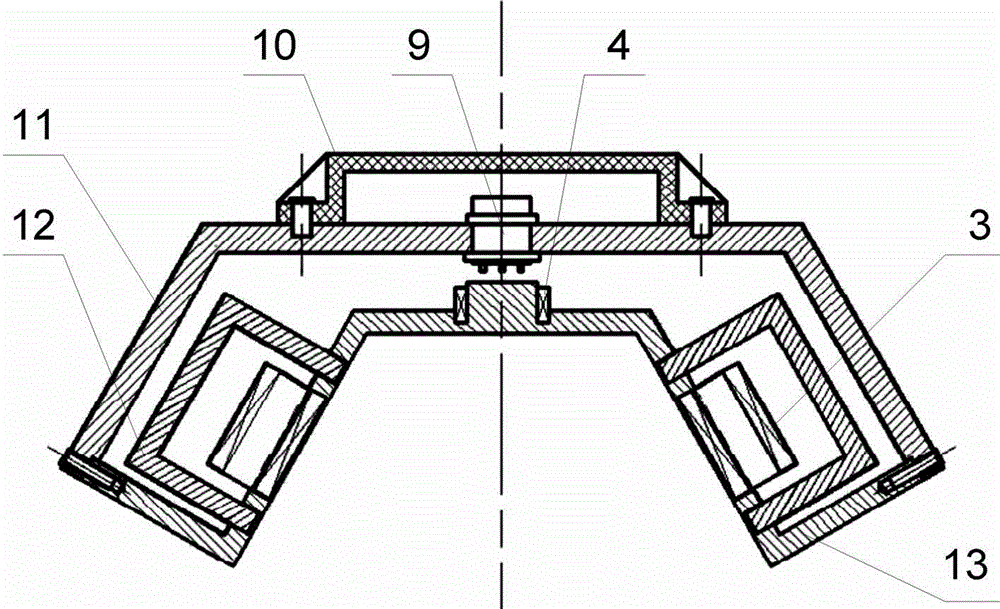

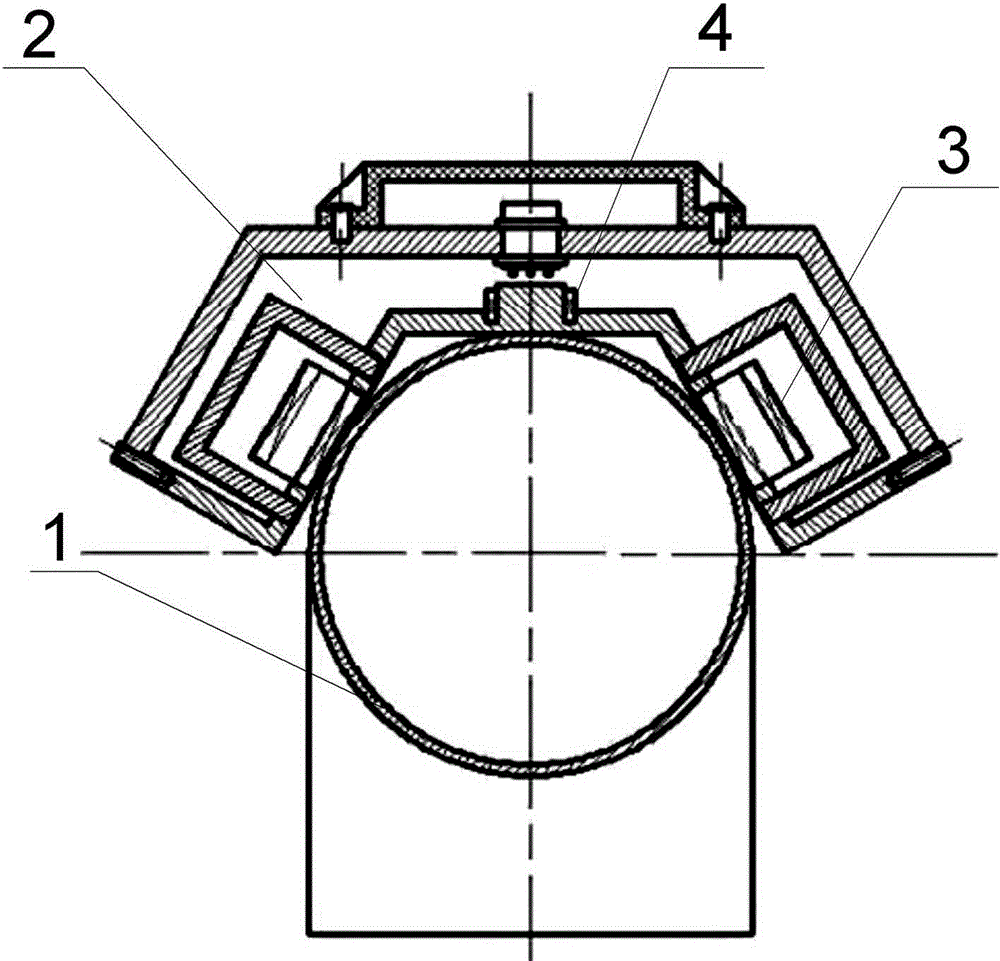

[0034] Example 1, see Figure 1-3 , The far-field eddy current sensor is arranged on the cross section of the pipe elbow 1; the excitation unit includes an excitation coil 3, the receiving unit includes a receiving coil 4, the axis of the excitation coil 3 is arranged along the circumference of the pipe elbow 1, and the receiving coil 4 The axis is arranged along the radial direction of the pipe elbow; the receiving coil 4 is located in the far-field area for measuring the indirect coupling magnetic field signal; a harmonic excitation is applied to the sensor excitation coil 3, and the changing excitation field causes a circumferential distribution along the cross section of the pipe elbow 1. The receiving coil 4 in the receiving unit is located in the far-field area to measure the indirect coupling magnetic field signal. The circumferential movement sensor scans the pipe elbow. The phase difference of the measured signal relative to the excitation signal indicates corrosion or c...

Embodiment 2

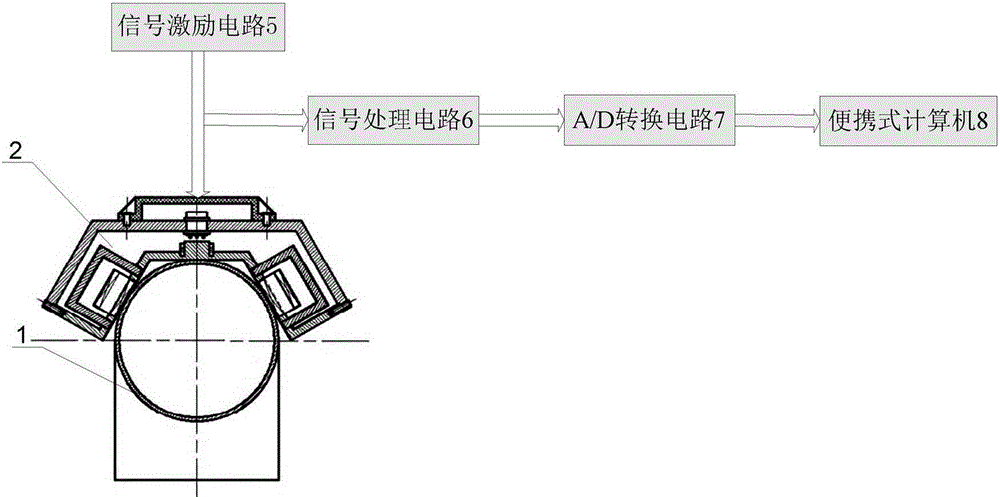

[0037] Example 2, see image 3 , The far-field eddy current sensor of the present invention is sequentially connected with the harmonic signal excitation circuit, signal processing circuit, A / D conversion circuit and computer. The harmonic signal excitation circuit provides harmonic excitation for the far-field eddy current sensor. On the outer surface of the pipe elbow, the eddy current is induced by excitation and the indirect coupling magnetic field signal is received in the far field area of the eddy current, which is converted into a voltage signal and transmitted to the signal processing circuit. The signal processing circuit amplifies, filters, and After comparison, they are sent to the A / D conversion circuit. The A / D conversion circuit converts the analog signal into a digital signal and sends it to the computer. The computer processes the received data to obtain the corrosion and crack defect information of the tested pipe elbow. Refer to Figure 1 to Figure 5 , The r...

Embodiment 3

[0038] Example 3, see Figure 1 to Figure 5 The pipeline elbow detection device of the present invention consists of a far-field eddy current sensor 2 composed of two identical excitation units and one receiving unit, and the two excitation units are respectively located on both sides of the receiving unit. The excitation unit includes an excitation coil 3, the receiving unit includes a receiving coil 4, the axis of the excitation coil 3 is arranged along the circumferential direction of the pipe elbow 1, the axis of the receiving coil 4 is arranged along the radial direction of the pipe elbow, and the receiving coil 4 is located in the measuring direction. The far field region of the coupled magnetic field signal. The far-field eddy current sensor 2 includes a housing 13, an end cover 11, an excitation coil 3, a receiving coil 4, and a socket. The socket may adopt the structure of an aviation socket 9 or other structures; the housing 13 is provided with an inner The cavity has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com