An enhanced heat dissipation liquid cooling radiator

A radiator and cooling liquid technology, applied in cooling/ventilation/heating transformation, etc., can solve the problems of increasing the flow resistance of liquid and the volume of the radiator, hot spots of heating components, and restricting the application of liquid-cooled radiators, etc. The effect of increased heat dissipation, improved efficiency, and reduced number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

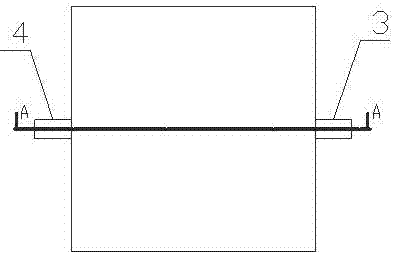

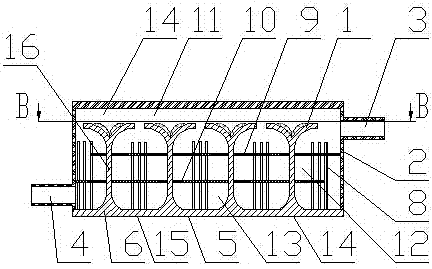

[0019] The schematic diagram of the enhanced heat dissipation liquid cooling radiator of the present invention is as follows Figure 1-Figure 5 As shown, it includes a sealed working chamber composed of a bottom plate 5 and an upper cover 2, the bottom of the upper cover 2 and the bottom plate 5 are fastened by welding or bolts, and the working chamber constitutes a space for circulating cooling medium. Inside the bottom plate 5 is an evaporation chamber 6 . The working chamber is provided with a plurality of cooling units, a plurality of rib columns 8 and a partition 9 parallel to the bottom plate 5, a first flow channel 11 is formed between the partition 9 and the top inner wall of the upper cover 2, A second flow channel 12 is formed between the partition plate 9 and the bottom plate 5, and the first flow channel 11 communicates w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com