Laser welding system and method

A laser welding, laser technology, applied in laser welding equipment, lasers, welding equipment and other directions, can solve problems such as limiting the overall welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] While the invention may take many different forms, for the purpose of facilitating an understanding of the principles of the invention, the invention will be described using specific language with reference to the embodiments shown in the drawings. It should be understood, however, that no limitation of the scope of the invention is thereby intended. Any changes and further modifications to the described embodiments, and any further applications of the principles described herein are considered to be within the normal range of those skilled in the art to which the invention pertains.

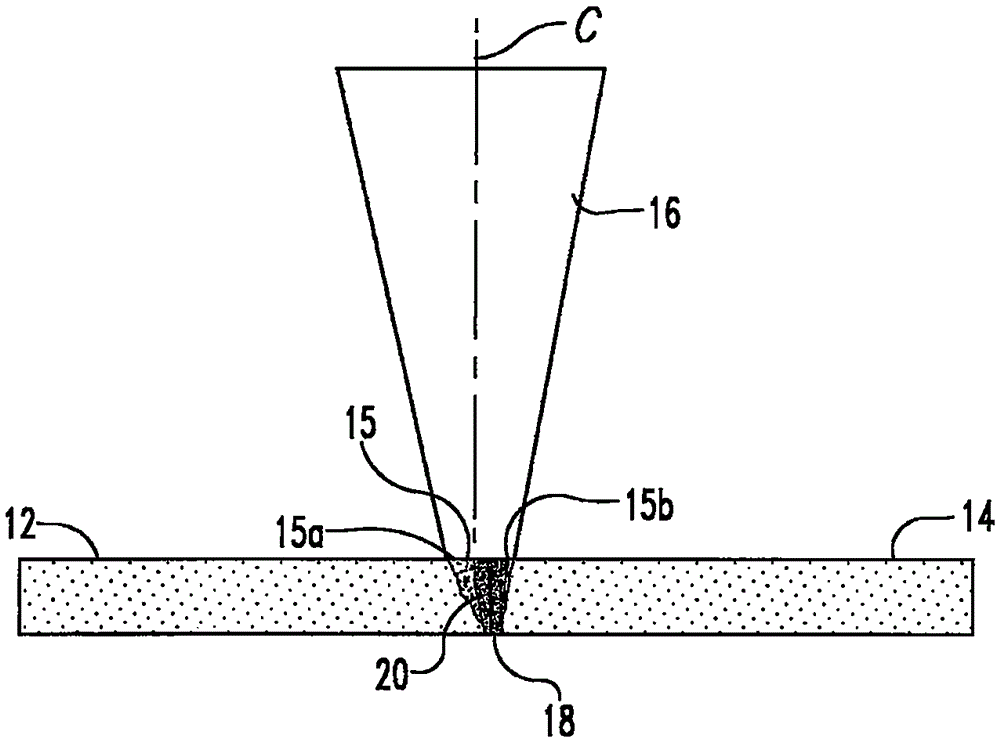

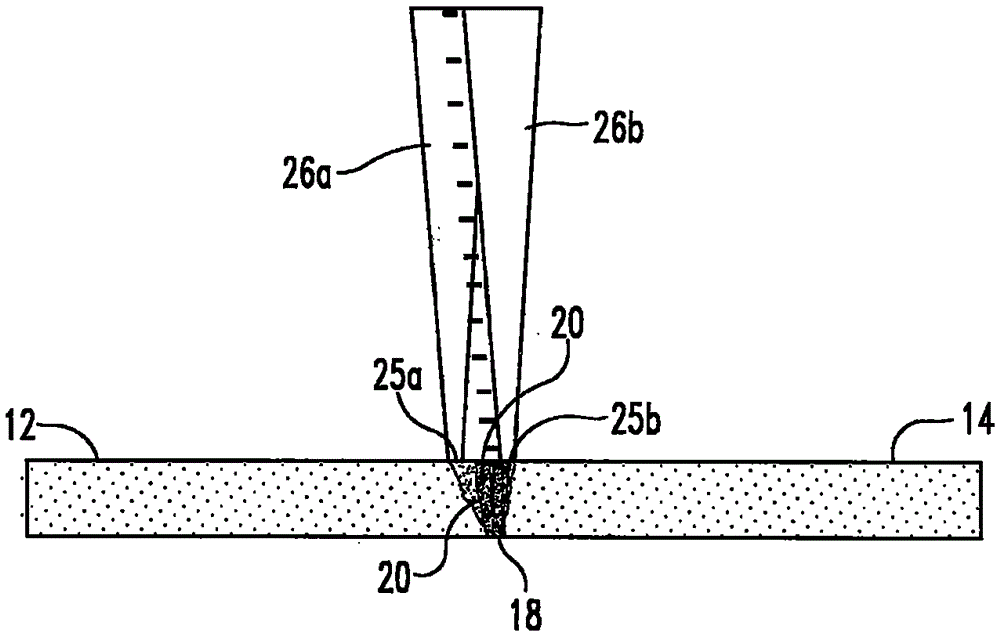

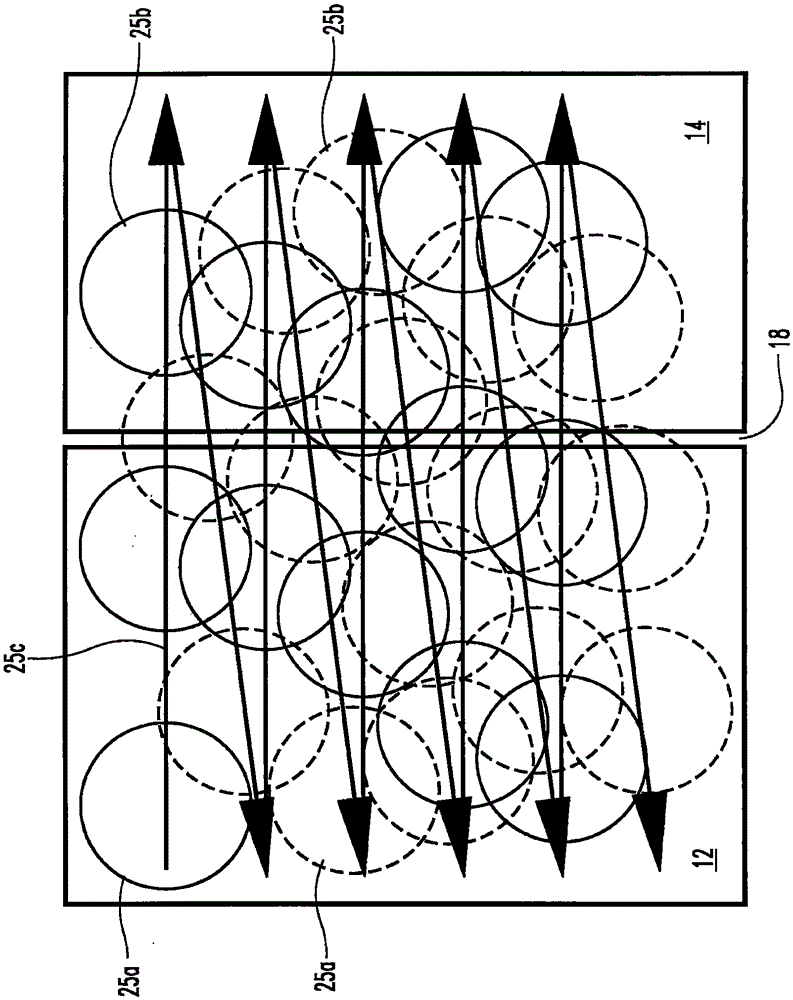

[0048] FIG. 1 shows a conventional method of laser welding dissimilar materials using a Nd:YAG laser 16 to weld a high melting point material 12 and a low melting point material 14 . A laser beam 16 is directed at the joint between the two materials. The beam spot 15 is large enough to span the small gap 18 at the material seam, one part 15a of the beam connects the high melting point ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com