Rudder driving system and method

A drive system and main drive technology, applied in the field of rudder drive system, can solve the problems of energy consumption, unfavorable propulsion performance, insufficient use of electric motors, etc., and achieve the effect of efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

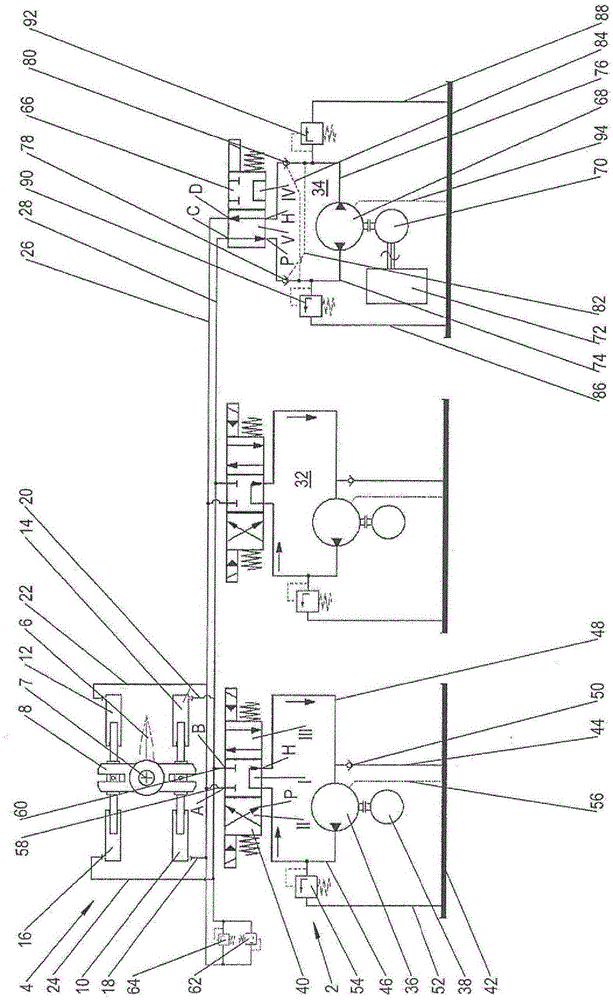

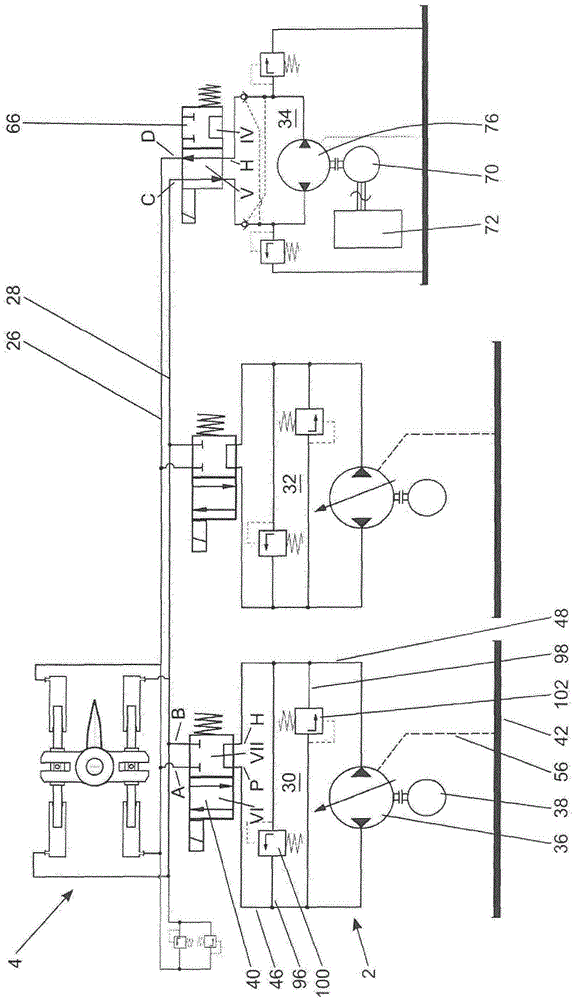

[0023] figure 1 A first embodiment of a rudder drive system 2 for steering a rudder device 4 of a ship according to the invention is schematically depicted in .

[0024] The rudder device 4 has a rudder or a rudder blade 6 which can be adjusted by a defined rotational angle about an axis of rotation 7 perpendicular to the plane of the rudder blade. The rudder or rudder blade is fastened to a beam 8 which can be swiveled by means of two cylindrical piston units 10 , 12 or 14 , 16 diametrically opposite each other at a corresponding angle of rotation. The cylindrical piston units 10 , 12 , 14 , 16 are fluidically connected to the working lines 18 , 20 , 22 , 24 respectively by means of connecting lines 26 , 28 between the rudder device 4 and the rudder drive system 2 .

[0025] The rudder drive system 2 has individually controllable electrohydraulic main drives 30 , 32 and an individually controllable electrohydraulic auxiliary drive 34 . Main drives 30 , 32 are designed redun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com