Method for fast and repeatable plasma ignition and tuning in plasma chambers

A plasma and process chamber technology that can be used in plasma, semiconductor/solid state device manufacturing, electrical components, etc., to solve problems such as changes in RF measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

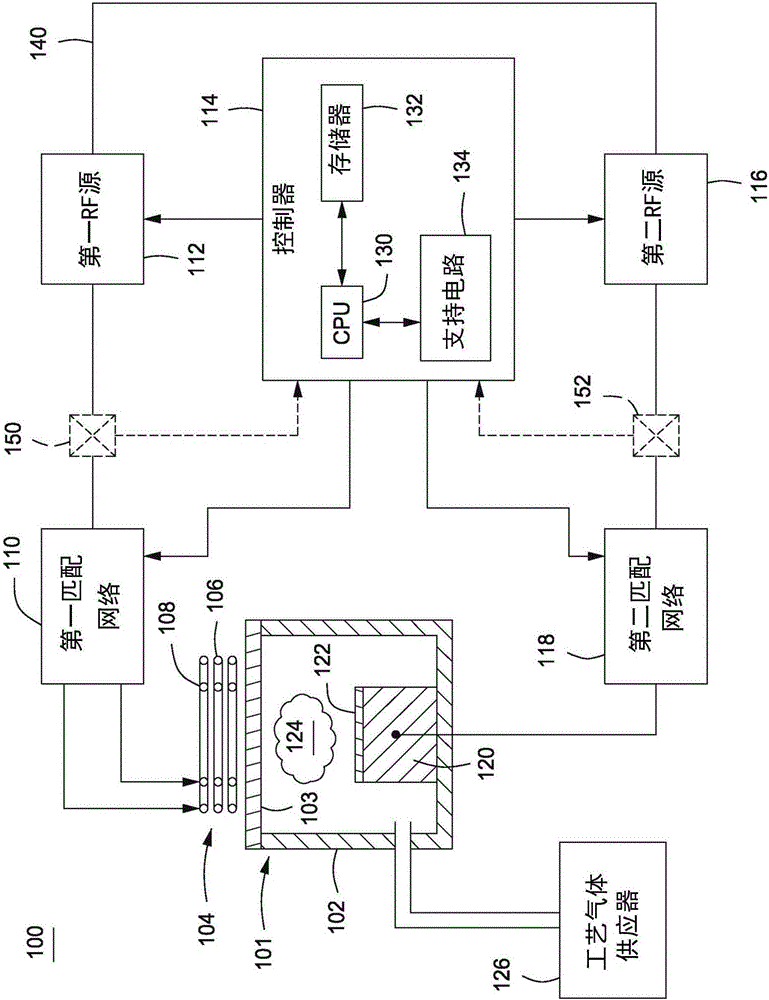

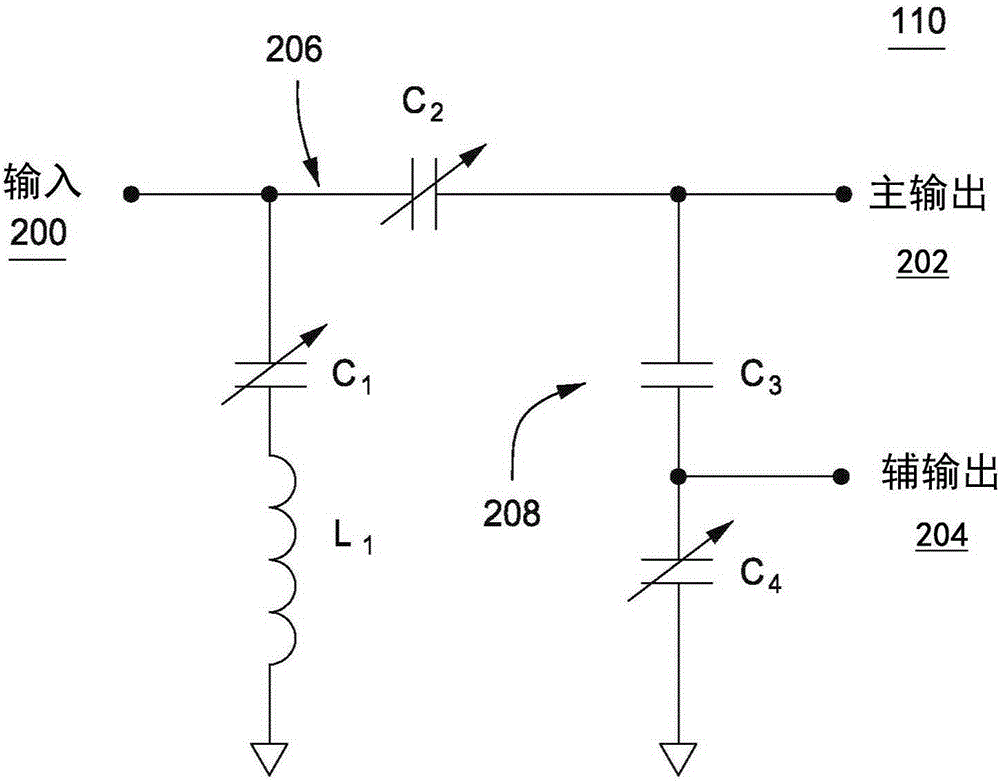

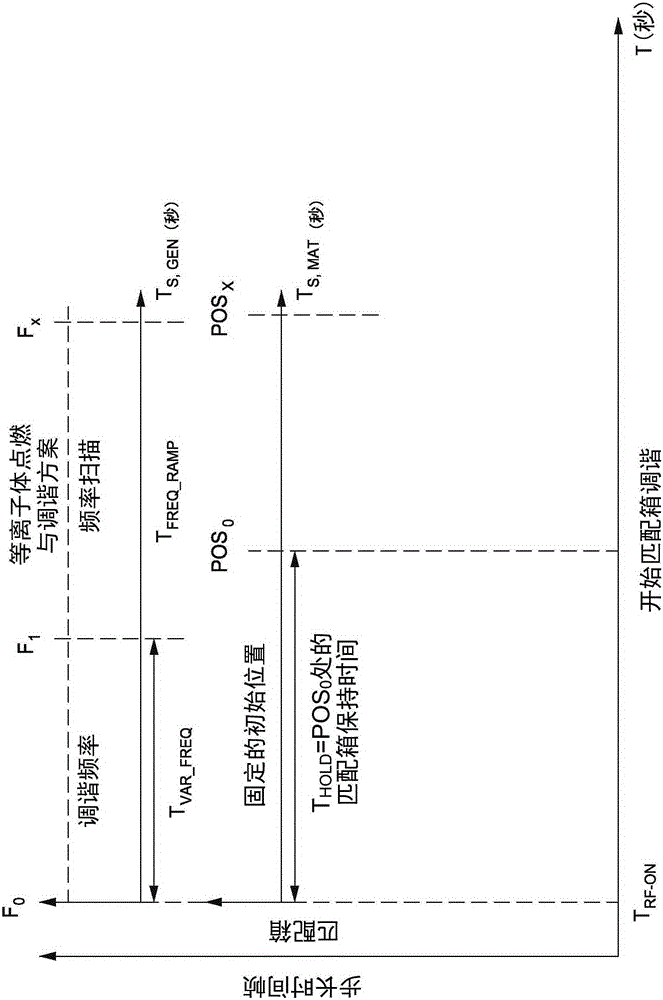

[0018] Embodiments of the present disclosure include methods and apparatus for igniting a plasma and / or switching across a plasma to reduce reflected power in a process chamber. Exemplary embodiments of the present disclosure provide methods and apparatus that combine a mechanical matching network with a variable frequency RF power generator with a set of timing rules. By operating these two tuning techniques in a suitable sequence and timing, fast and repeatable plasma ignition and / or tuning is possible with repeatable end frequency and plasma distribution. In some embodiments, a combined system for fast and repeatable plasma ignition and / or tuning is run-to-run and wafer-to-wafer for on-wafer process results Aspects of repeatability contribute to better process performance. Embodiments of the present disclosure provide steps that allow for a repeatable and stable operating window for use of an RF generator with frequency tuning (also referred to as frequency sweeping) in co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com