Machining method and threaded pipe die for reverse extrusion threads of thin-walled stainless steel pipes

A technology of stainless steel pipe and reverse extrusion, which is applied in the direction of metal extrusion dies, etc., can solve the problems of unacceptable product prices and high costs for customers, and achieve the effect of expanding market sales and low product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing with specific embodiment:

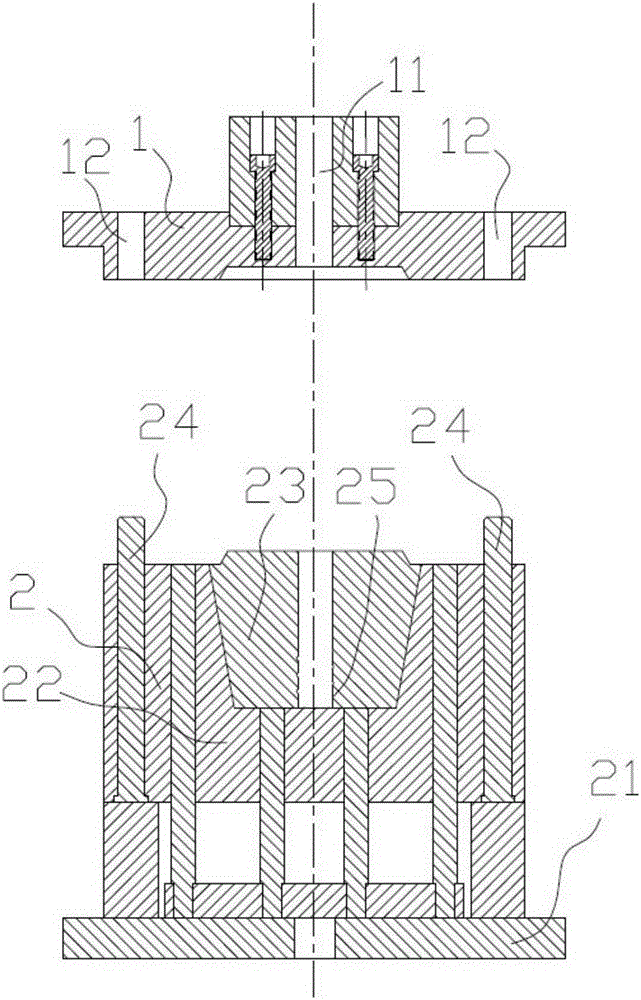

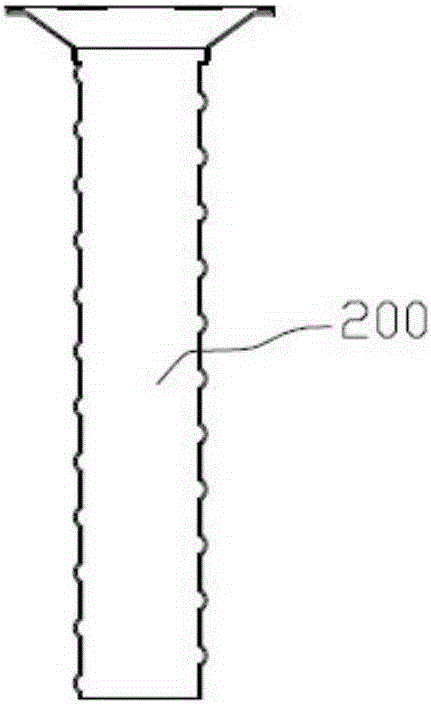

[0025] A method for processing thin-walled stainless steel pipe reverse extrusion threads, which comprises the following steps: a. first prepare a stainless steel pipe blank with a suitable pipe diameter, the stainless steel pipe blank is thin-walled, and the wall thickness is 0.2 to 0.5mm, and then , the stainless steel pipe blank is cut off according to the length requirement as the processing pipe material; b. Prepare a section of polyurethane round bar according to the length of the processing pipe material, the diameter of the round bar is 0.18-0.23mm smaller than the inner diameter of the pipe material, and the length of the round bar is Need to press 1.1 to 1.3 times the length of the thread; c. Prepare the spiral tube mold, the cavity of the mold has internal threads, put the processed tube material into the cavity of the mold, and put the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com