Horizontal joint mechanical arm

A technology of mechanical arms and horizontal joints, applied in the directions of manipulators, claw arms, manufacturing tools, etc., can solve the problems of low precision and high maintenance costs, and achieve the effect of reducing warranty costs and simplifying complex structural configurations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

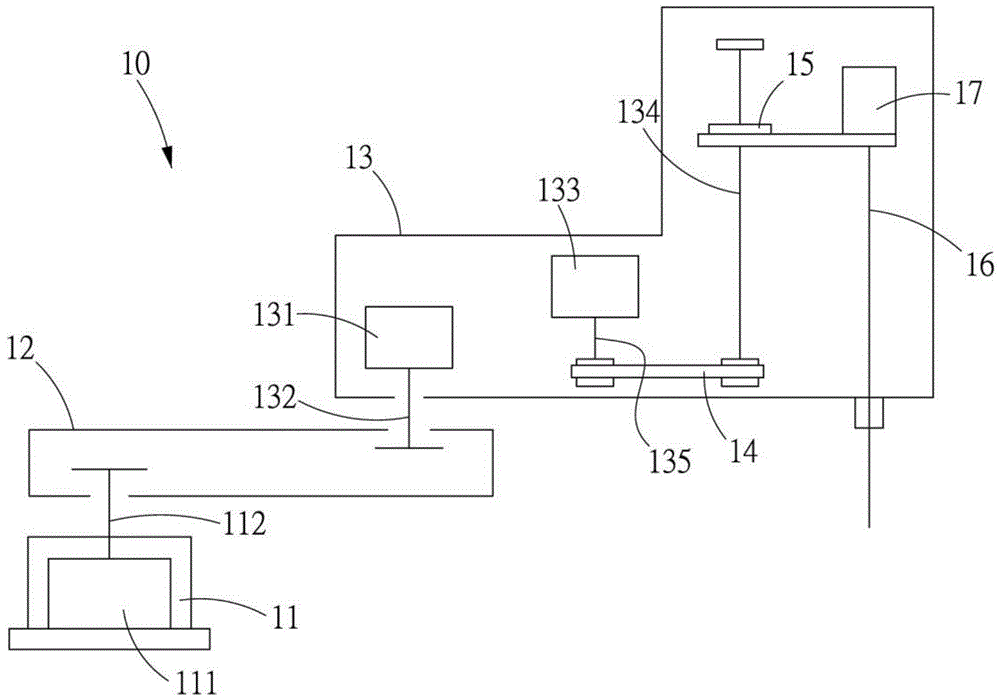

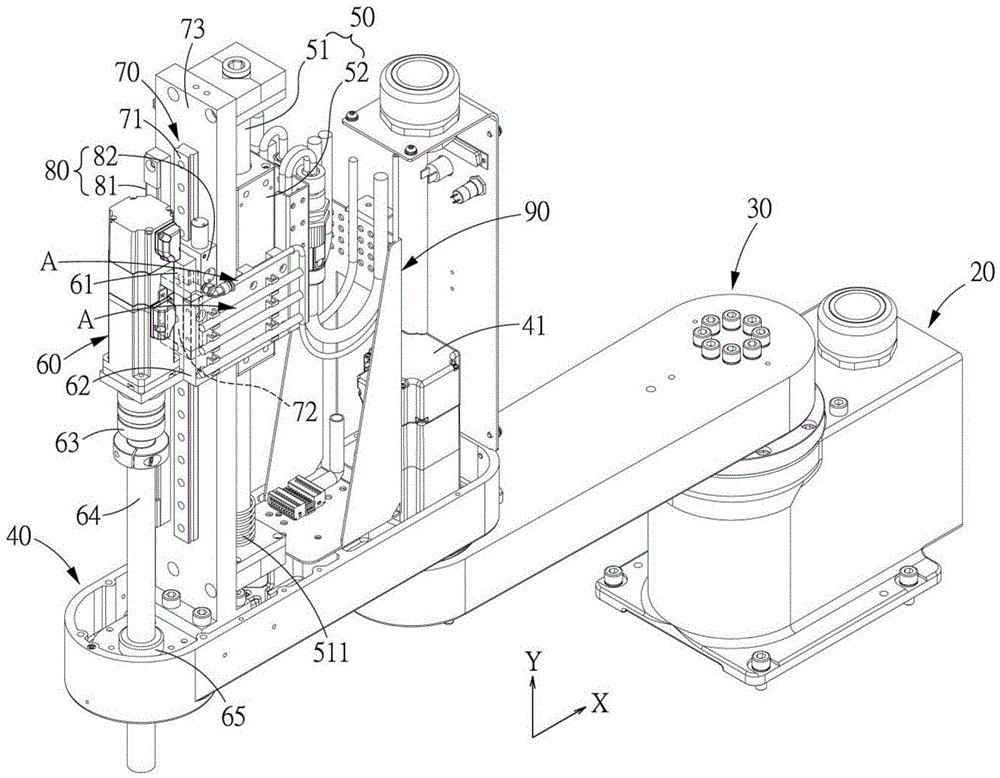

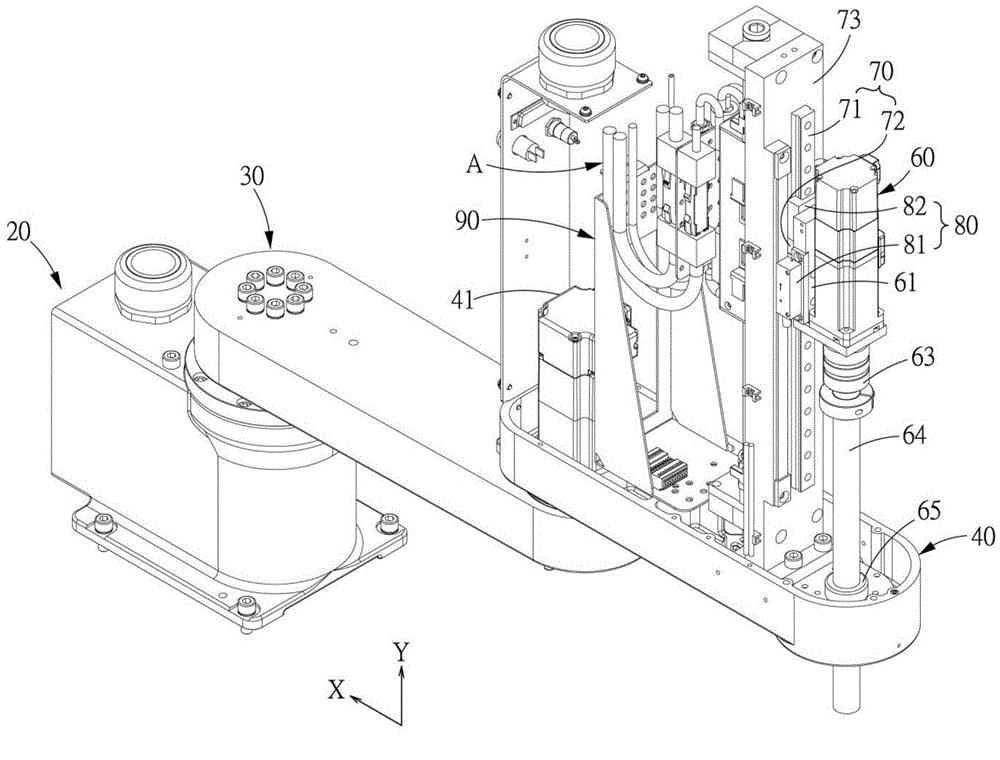

[0051] A preferred embodiment of a horizontally articulated mechanical arm of the present invention is Figures 2 to 6 shown, including:

[0052] A pedestal 20 is provided for fixed arrangement on the ground or a fixed plane, and the pedestal 20 is fixedly provided with a first shaft motor 21, and the first shaft motor 21 drives a first drive shaft 211 to rotate, and the first drive shaft 211 extends along a vertical direction Y, and the vertical direction Y is defined as the horizontal direction X. The first driving shaft 211 is combined with a first reduction mechanism 22, so that the first shaft motor 21 passes through the first The reduction mechanism 22 outputs power.

[0053] A first arm 30, one end is combined with the first reduction mechanism 22 on the first shaft motor 21, so that the first arm 30 is combined with the first shaft motor 21, then the first arm 30 can be controlled by the first shaft motor 21. The first axis motor 21 drives the rotation, and makes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com