Special cutter for specially-shaped angle

A cutting machine and special-shaped technology, which is applied in the field of special-shaped corner cutting machines, can solve the problems of inconvenient operation, tired hands, and poor cutting corner effects, etc., and achieve good cutting effect and easy and convenient operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

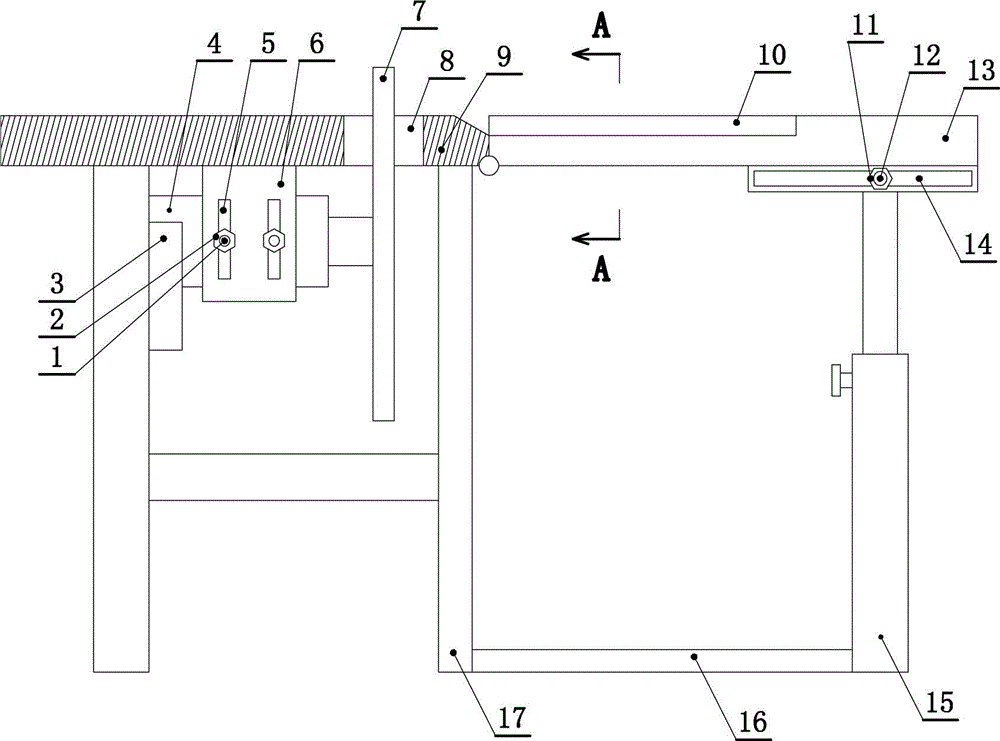

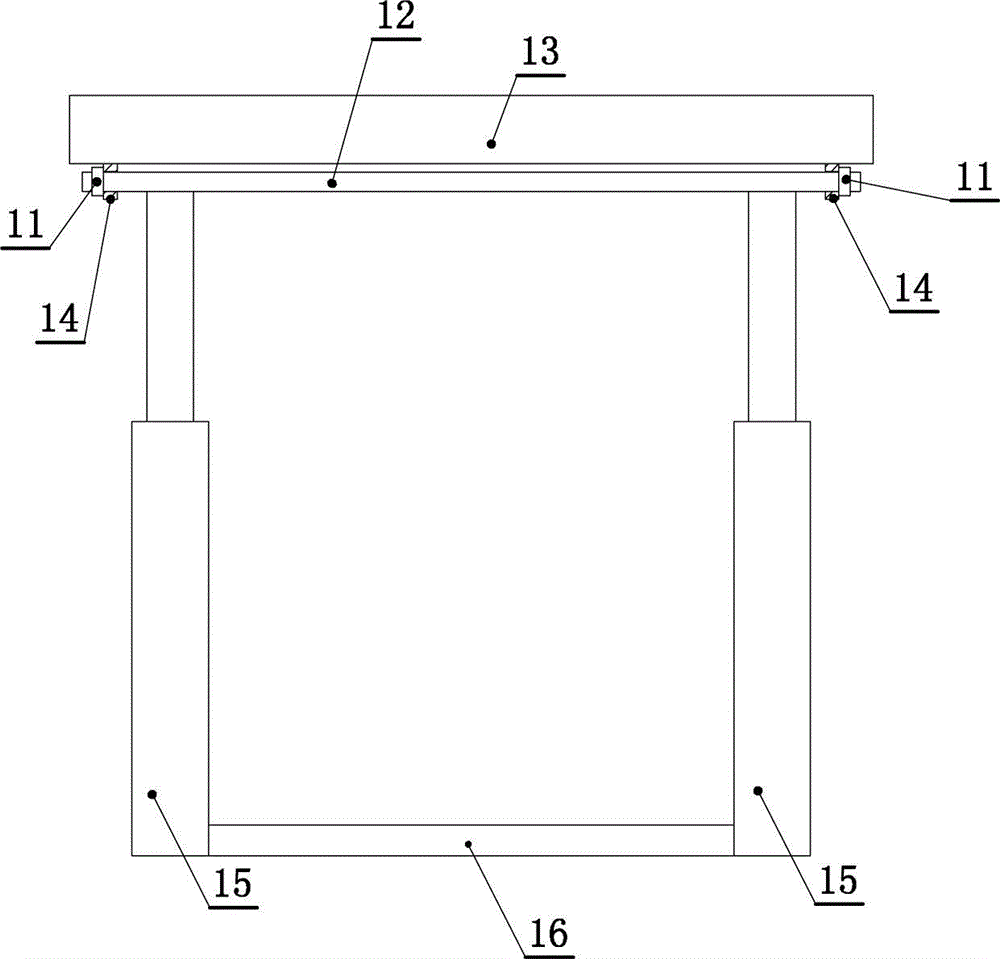

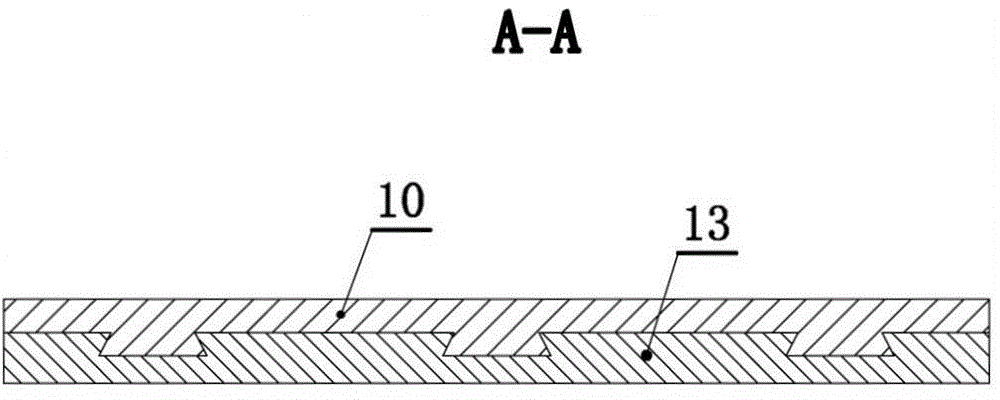

[0021] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0022] Such as figure 1 , figure 2 and image 3 As shown, a special-shaped cutting machine for special-shaped corners includes a support leg 17, the upper end of the support leg 17 is fixedly connected with a fixed table 9, and a long strip-shaped cutting port 8 is provided on the fixed table 9, and a motor 4 is fixedly installed under the fixed table 9. , Motor 4 transmission is connected with cutting disc 7, and cutting disc 7, the edge upper end of cutting disc 7 passes through cutting opening 8 to above fixed table top 9, and above structure just makes the present invention possess the function of common cutting.

[0023] The edge of the fixed table 9 outside the cutting opening 8 is hinged with a movable ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com