Table type centrifugal machine

A centrifuge and desktop technology, applied in the direction of centrifuges, etc., can solve the problems of inconvenient operation process, achieve the effect of easy and convenient operation process, easy and convenient use process, and improve the convenience of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

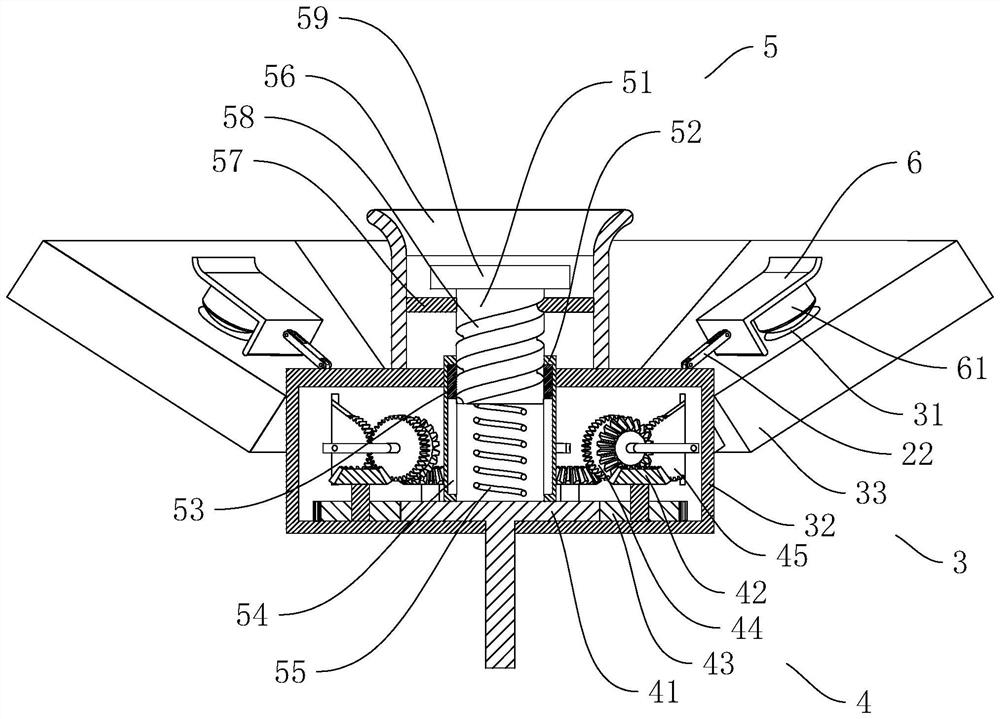

[0034] The following is attached Figure 1-4 The application is described in further detail.

[0035] The embodiment of the present application discloses a desktop centrifuge.

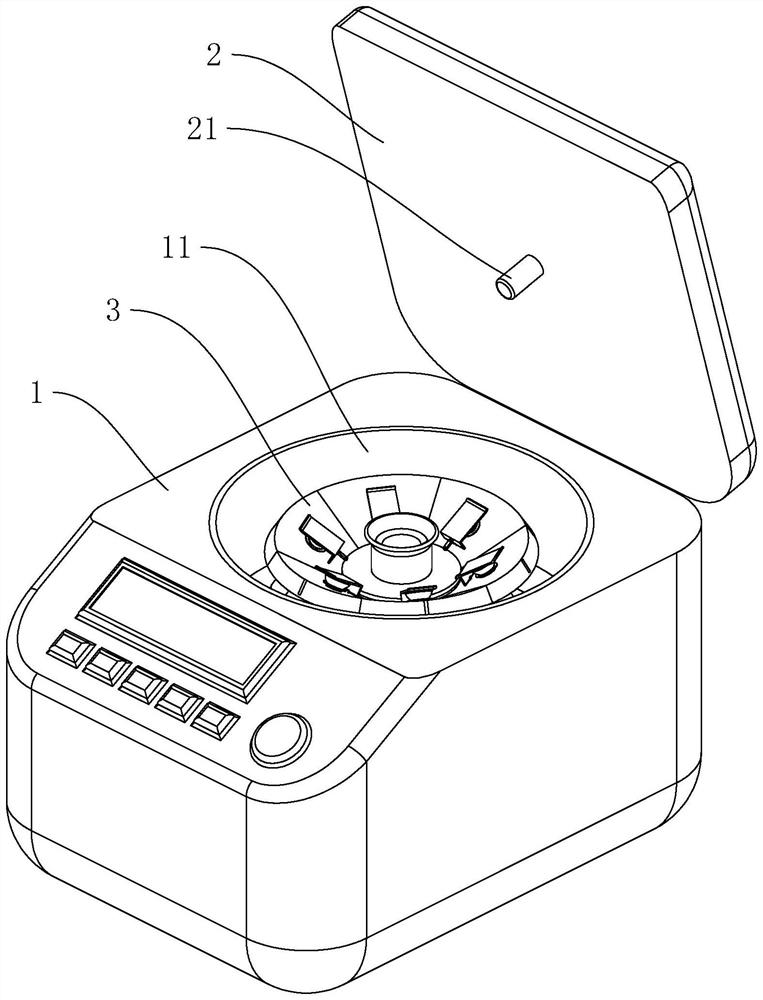

[0036] refer to figure 1 , figure 2 , the desktop centrifuge includes a body 1 , a cover plate 2 and a rotor body 3 . The body 1 is provided with a centrifugal chamber 11 , the centrifugal chamber 11 runs through the upper surface of the body 1 , and the cover plate 2 is hingedly arranged on the body 1 and is used to cover the centrifugal chamber 11 .

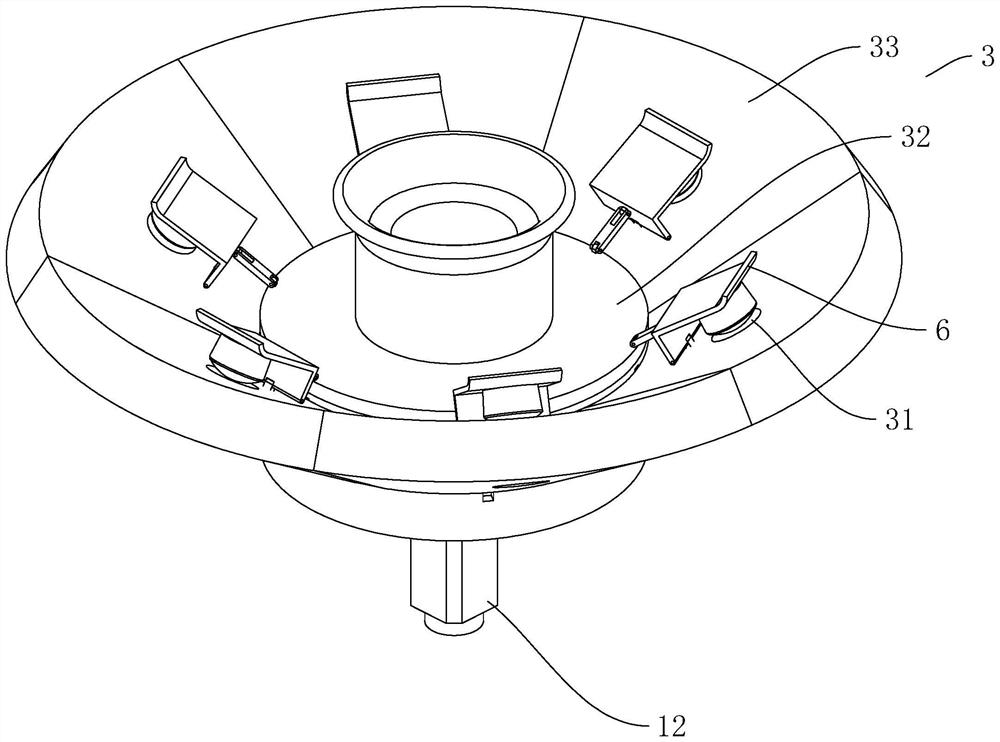

[0037] refer to figure 1 , figure 2 , the rotor body 3 is located in the centrifugal chamber 11, the central axis of the rotor body 3 is arranged in line with the central axis of the centrifugal chamber 11, and the motor 12 for controlling the rotation of the rotor body 3 is arranged in the centrifugal chamber 11. There is also a circle of test holes 31 distributed on the rotor body 3 , the upper ends of the test holes 31 are close to each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com