Side wall assembly of open wagon special for railway ore

A side wall and ore technology, which is applied in the field of side wall assemblies of railway ore gondolas, can solve the problems of easy accumulation of goods, unsuitable cleaning methods, and inconvenient cleaning of residual goods, etc., and achieves weight reduction, novel appearance, and connection. Reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

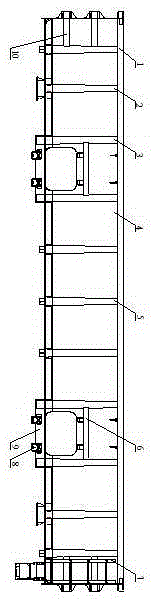

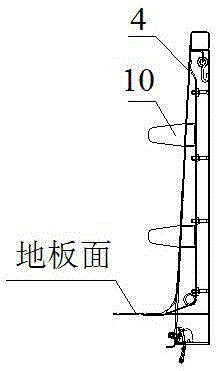

[0026] Such as figure 1 , Figure 5 As shown, it consists of 1 upper side beam 1, 2 pillow columns 2, 4 side columns (1) 3, 1 side wall panel 4, 5 side columns 2 6, 2 door beams 6, and 1 escalator 7. 4 pieces of locking mechanism 8, 2 pieces of door panels 9, 4 pieces of horizontal belts 10 and 4 pieces of hanging rings.

[0027] The upper side beam 1 is cold-formed 100mm×100mm×5mm square steel, and the upper side beam and the upper end beam are in the same horizontal plane, which is suitable for pressing beams of different dumpers, and can press side beams and end beams. Pillow column 2, side column 1 3, and side column 2 5 are all U-shaped cross-sections with arcs, which can be made by the same mold in technology. According to the lateral pressure distribution of bulk goods, the variable pressure gradually increases from top to bottom. Section type. Holes are processed on the pillow column 2, and round steel pipes are assembled and welded in the holes to increase the lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com