Winding drum replacing and bag laying mechanism for submarine bag laying device

A bag laying device and reel technology, which is applied in the directions of winding strips, transportation and packaging, thin material processing, etc., can solve problems that threaten the safe operation of submarine pipelines, and achieve the effect of improving device operation efficiency and safe and reliable rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in more detail below in conjunction with accompanying drawing example:

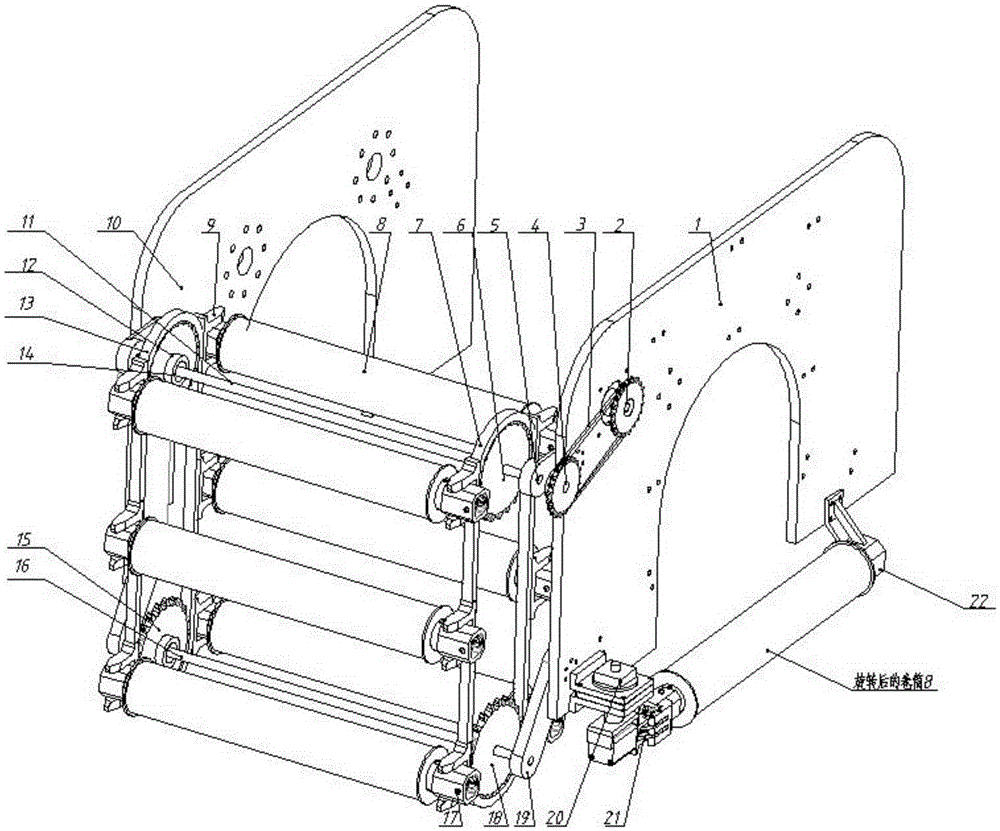

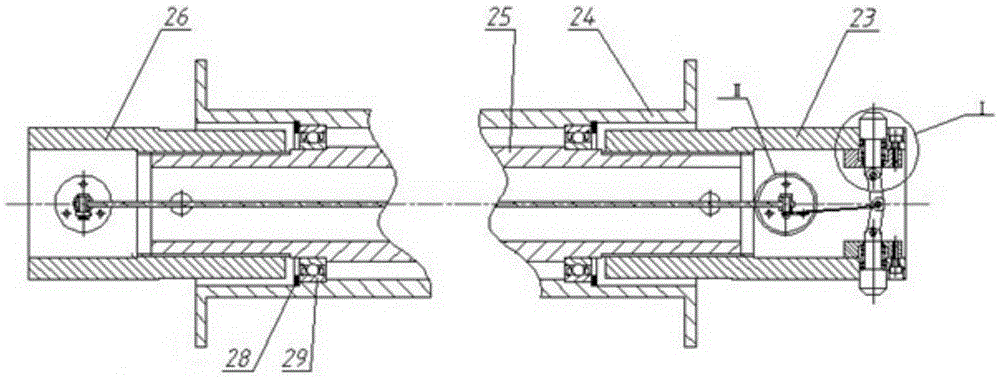

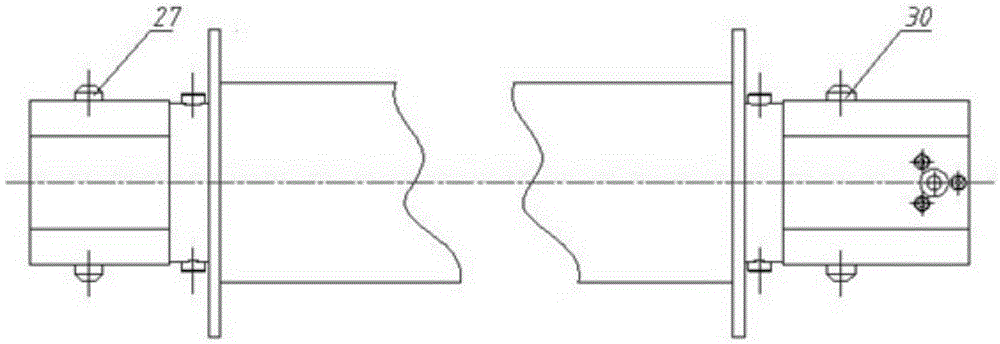

[0022] combine Figure 1~4 , install the upper sprocket mounting plate 5 and the sprocket lower mounting plate 19 on the support plate A1, and at the same time, find out the horizontal corresponding positions of the sprocket upper mounting plate 5 and the sprocket lower mounting plate 19 installation positions on the support plate B10, and Install a set of sprocket upper mounting plate 5 and sprocket lower mounting plate 19 on the support plate B10, install the first sprocket shaft 11 between the support plate A1 and the sprocket upper mounting plate 5 corresponding to the horizontal position on the support plate B10 In order to allow the first sprocket shaft 11 to rotate freely, rolling bearings are installed on both sides of the first sprocket shaft 11 and the sprocket upper mounting plate 5 respectively, and the expansion sleeve 14 is used on the first sprocket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com