A dust removal method for pulverized coal pyrolysis high temperature gas

A hot coal gas and coal gas technology, which is applied in the dust removal of pulverized coal pyrolysis high temperature gas and high temperature gas, can solve the problems of high cost of dust removal process and difficult recycling of waste, etc., achieve low cost of dust removal, realize comprehensive utilization, and facilitate industrialization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

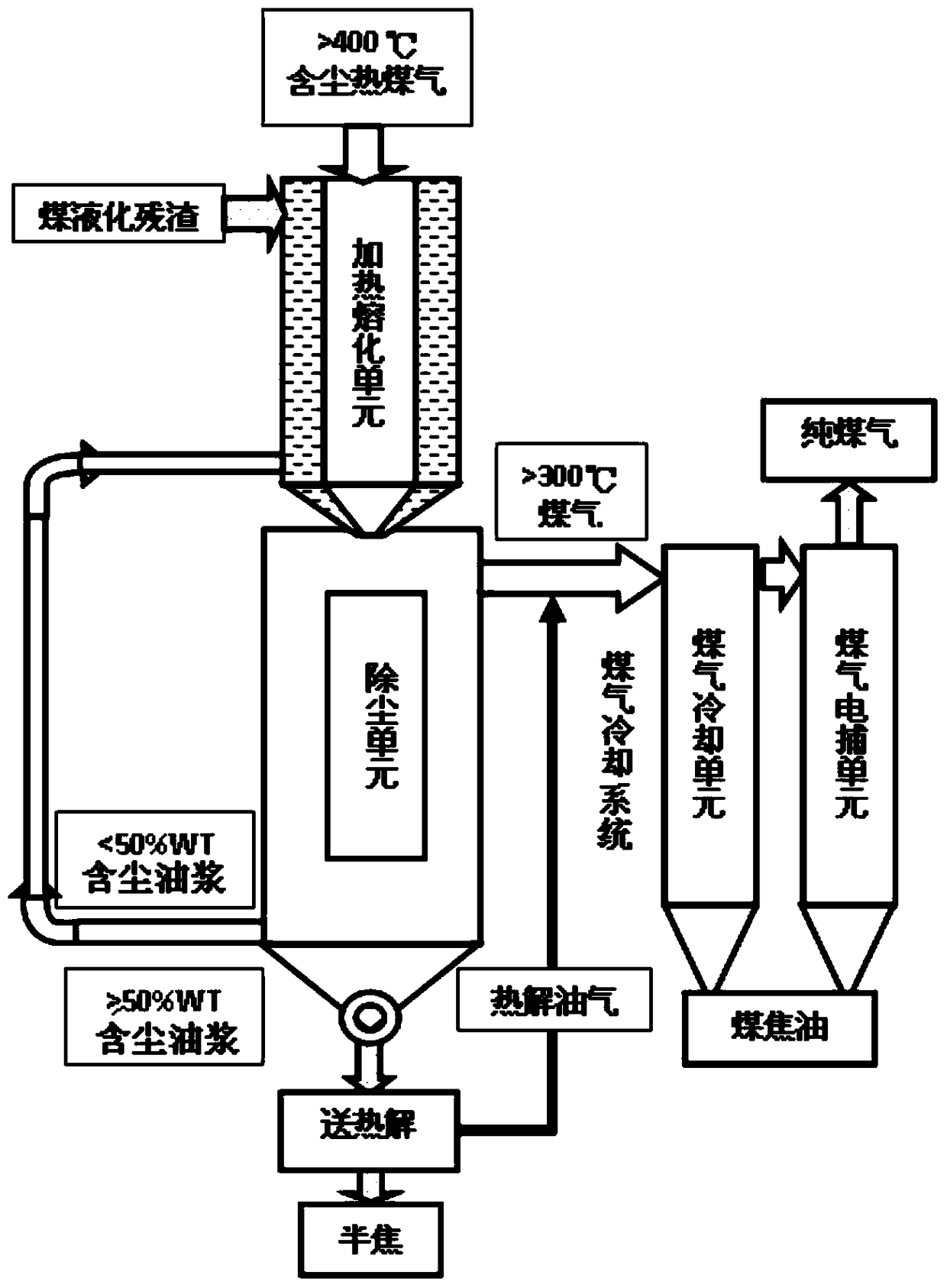

[0028] This embodiment provides a kind of dedusting method of pulverized coal pyrolysis high-temperature gas, such as figure 1 As shown, the dusty hot gas and coal liquefaction residue with a temperature higher than 400 °C are passed into the heating and melting unit, and the coal liquefaction residue is heated to a liquid state. The melting of the coal liquefaction residue is realized by the heating unit, and the heat source comes from the heat output The physical heat of the dust-laden gas whose temperature is higher than 400°C in the furnace can also be an external heat source. The temperature of the coal liquefaction residue in the liquid state is in the range of 300°C to 360°C, then the dusty hot gas and the coal liquefaction residue in the liquid state are sent to the dust removal unit for contact washing, and the temperature in the dust removal unit is also 300 In the range of ℃ ~ 360 ℃, the coal liquefaction residue in the liquid state is used as the dust removal mediu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap