Double-layer sealing access door of bag type dust remover

A bag-type dust collector and double-layer sealing technology, applied in sealing devices, chemical instruments and methods, dispersed particle filtration, etc., can solve the problems of large structural changes, high air leakage rate, poor sealing effect, etc. Simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

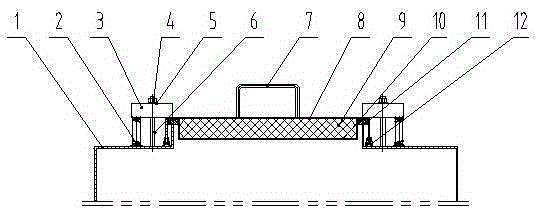

[0016] This specific embodiment provides a double-layer sealed maintenance door for bag type dust collector, including dust removal box body 1, spring 2, compression block 3, compression nut 4, gasket 5, fixed stud 6, handle 7, maintenance door Panel 8, thermal insulation rock wool 9, lower seal 10, square sealing strip 11, Y-shaped sealing strip 12.

[0017] One end of the spring 2 is welded and fixed on the dust removal box 1, and the other end is fixed on the outer side below the pressing block 3 to support the pressing block 3, and the other side of the pressing block 3 is rested on the inspection door panel 8, and the fixing stud 6 passes through it. The center of the pressing block 3 is welded on the dust removal box body 1, and the pressing block 3 is pressed against the inspection door panel 8 by the pressing nut 4 and the was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com