Controllable double-protection fall lift spring safety valve and boiler steam-water system

A dual-protection and controllable technology, applied in the field of safety valves, can solve the problems of not being able to open and discharge steam in time, and achieve the effects of non-interference between mechanical and electrical actions, rapid action, and accurate setting pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

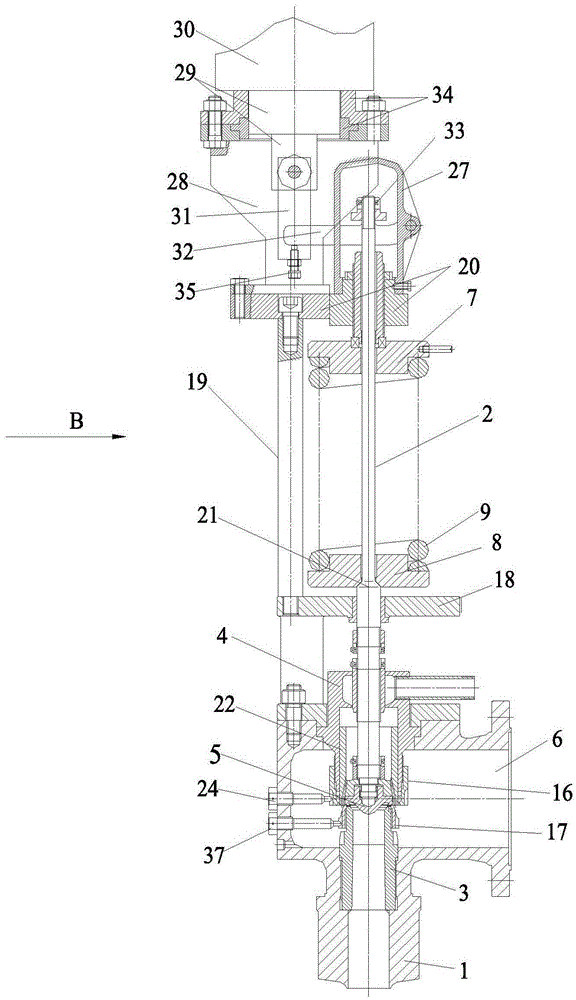

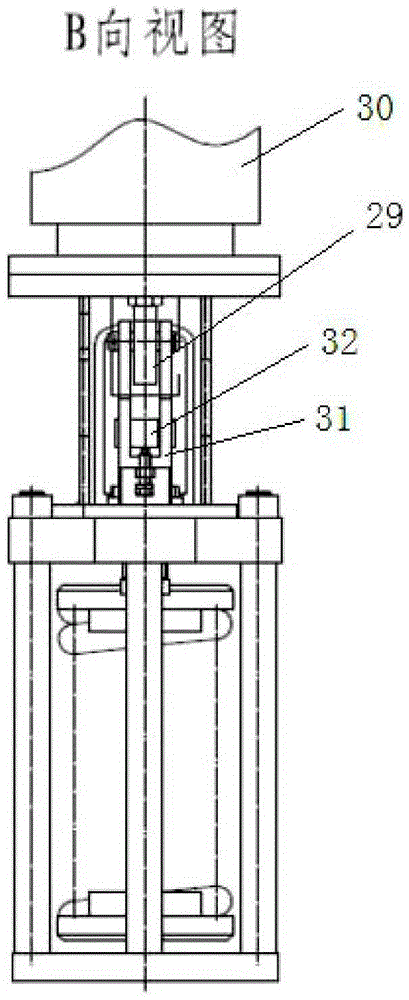

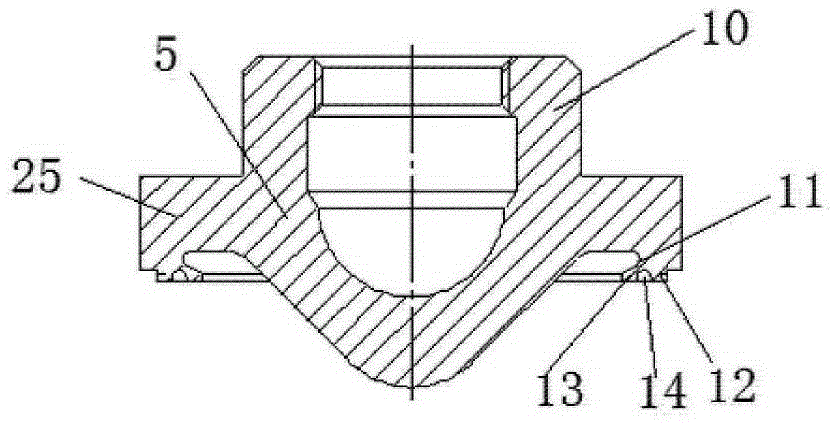

[0027] Such as figure 1 , figure 2 As shown, the present invention includes a valve body 1 and a valve stem 2, a valve seat 3 is provided at the lower part of the inner cavity of the valve body 1, a guide sleeve 4 is provided at the top opening of the inner cavity of the valve body 1, and a guide sleeve 4 is provided at the lower part of the valve stem 2. Penetrates into the guide sleeve 4, and the bottom end of the valve stem 2 is linked with a valve flap 5 that can seal fit with the valve seat 3, and the valve flap 5 is coaxially sleeved with a recoil disc 22, so The valve body 1 is horizontally provided with an exhaust port 6 corresponding to the top position of the valve seat 3, and the upper part of the valve stem 2 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com