Method for measuring end face spatial displacement and angular variation of shafting engineering member on the basis of stay-supported displacement sensors

A displacement sensor and space displacement technology, applied in measuring devices, instruments, etc., can solve the problems of inability to measure the displacement and angular change of resistance strain gauges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below with reference to the accompanying drawings.

[0033] The purpose of the invention is a method for measuring the spatial displacement and angular change of the end face of a shaft engineering component based on a wire-pull displacement sensor.

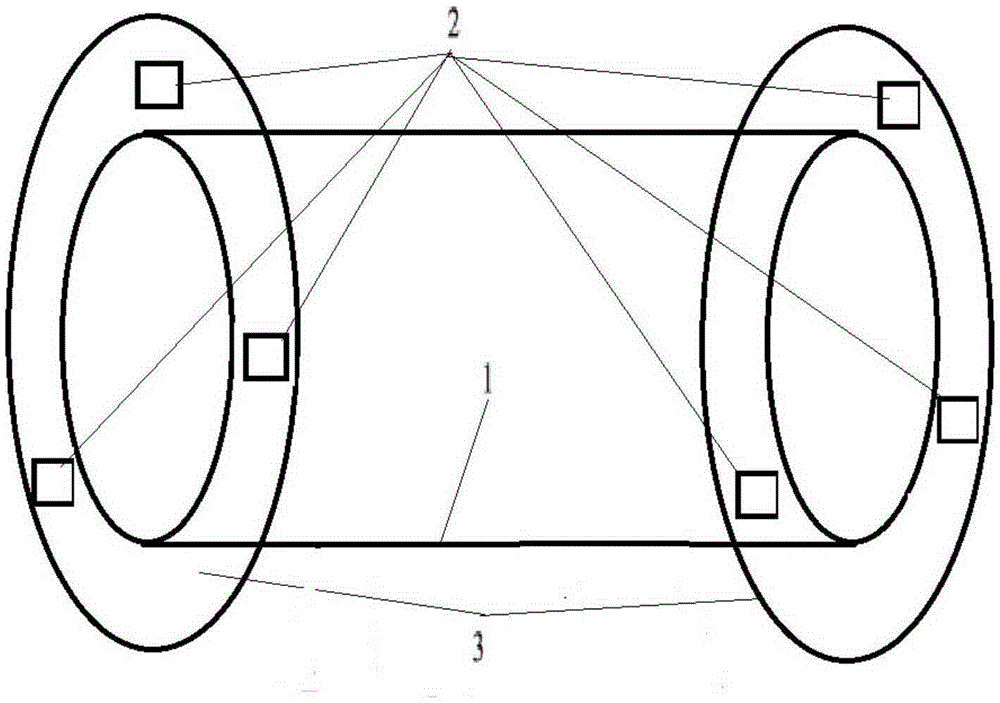

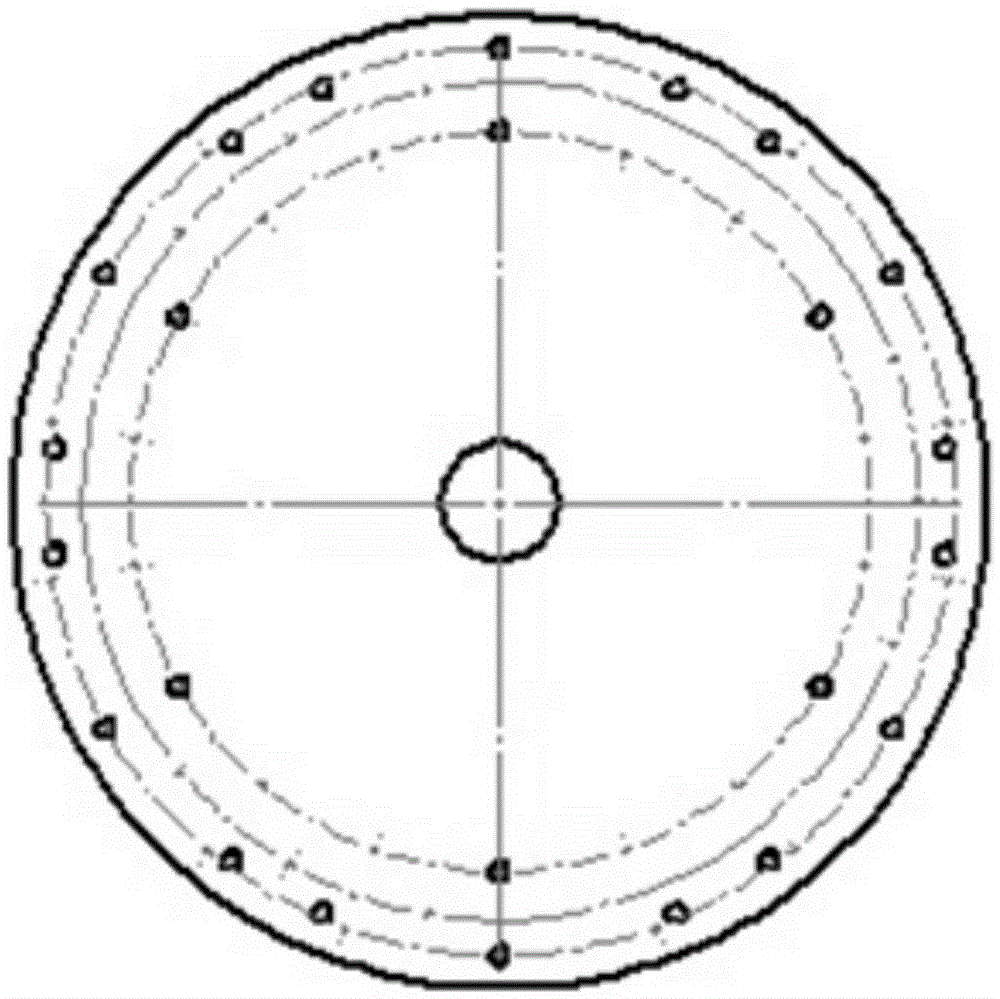

[0034] The principle of the present invention: First, install three pull-wire displacement sensors at three points where the distance can be measured on both ends of the measurable shaft system, and install three pull-wire displacement sensors at three points where the relative distance can be measured on the end face of the measured shaft system . The placement of these six sensors can be arbitrarily selected, and two flanges can be designed to be installed on the end face of the shaft system. Take the sensor positions of the measurable end face as A, B, and C, and the sensor positions of the measured end face as D, E, and F. Then, interconnect the three pull-wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com