A blast furnace molten iron sampling device

A sampling device and blast furnace molten iron technology, applied in the direction of sampling devices, etc., can solve the problems of randomness, instability, and scalding of hot samples in traditional sampling methods, and achieve simple and reliable operation and standing, low cost, and eliminate randomness. sex and instability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the purpose, structure and function of the present invention, a blast furnace molten iron sampling device of the present invention will be further described in detail below in conjunction with the accompanying drawings.

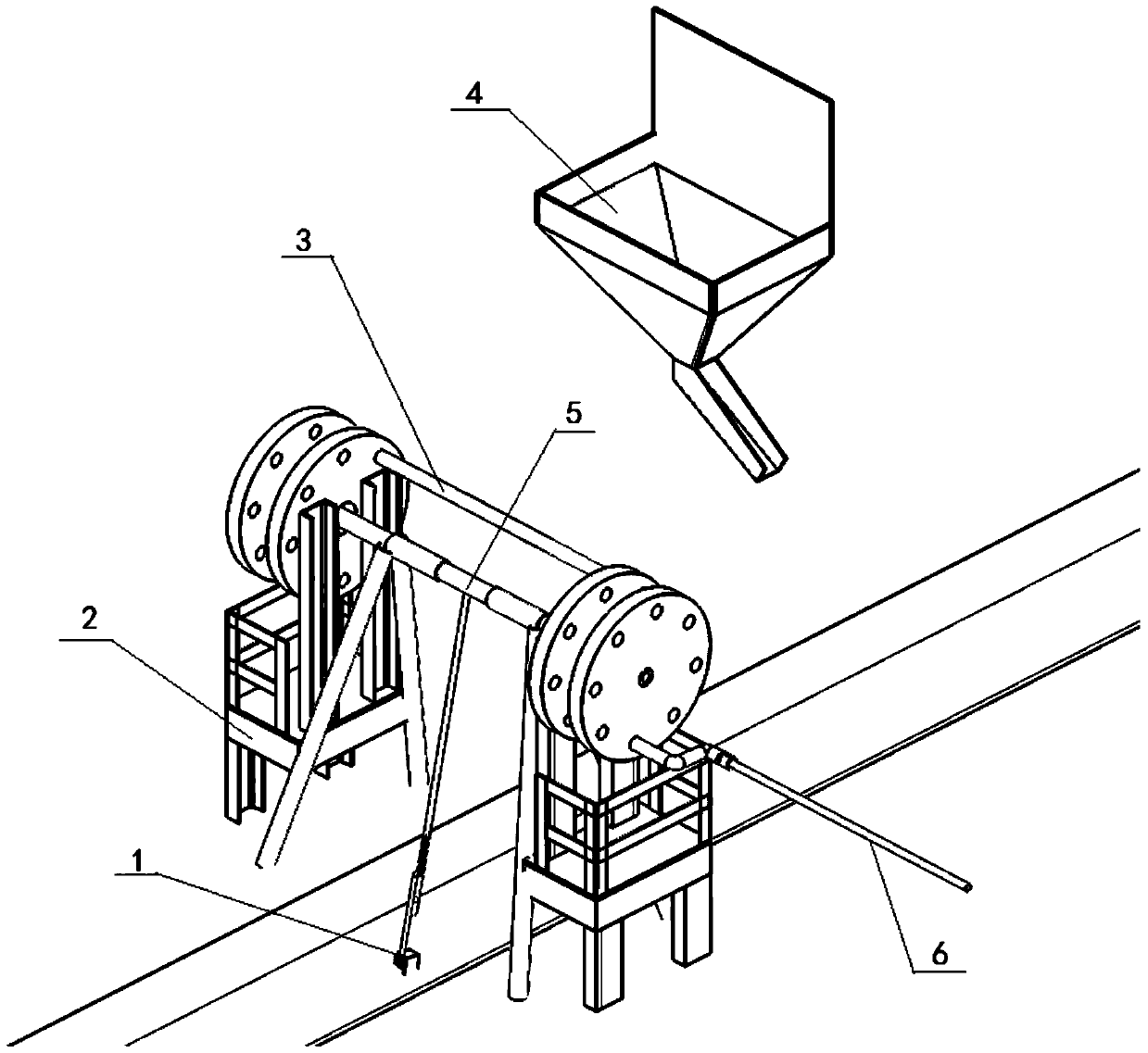

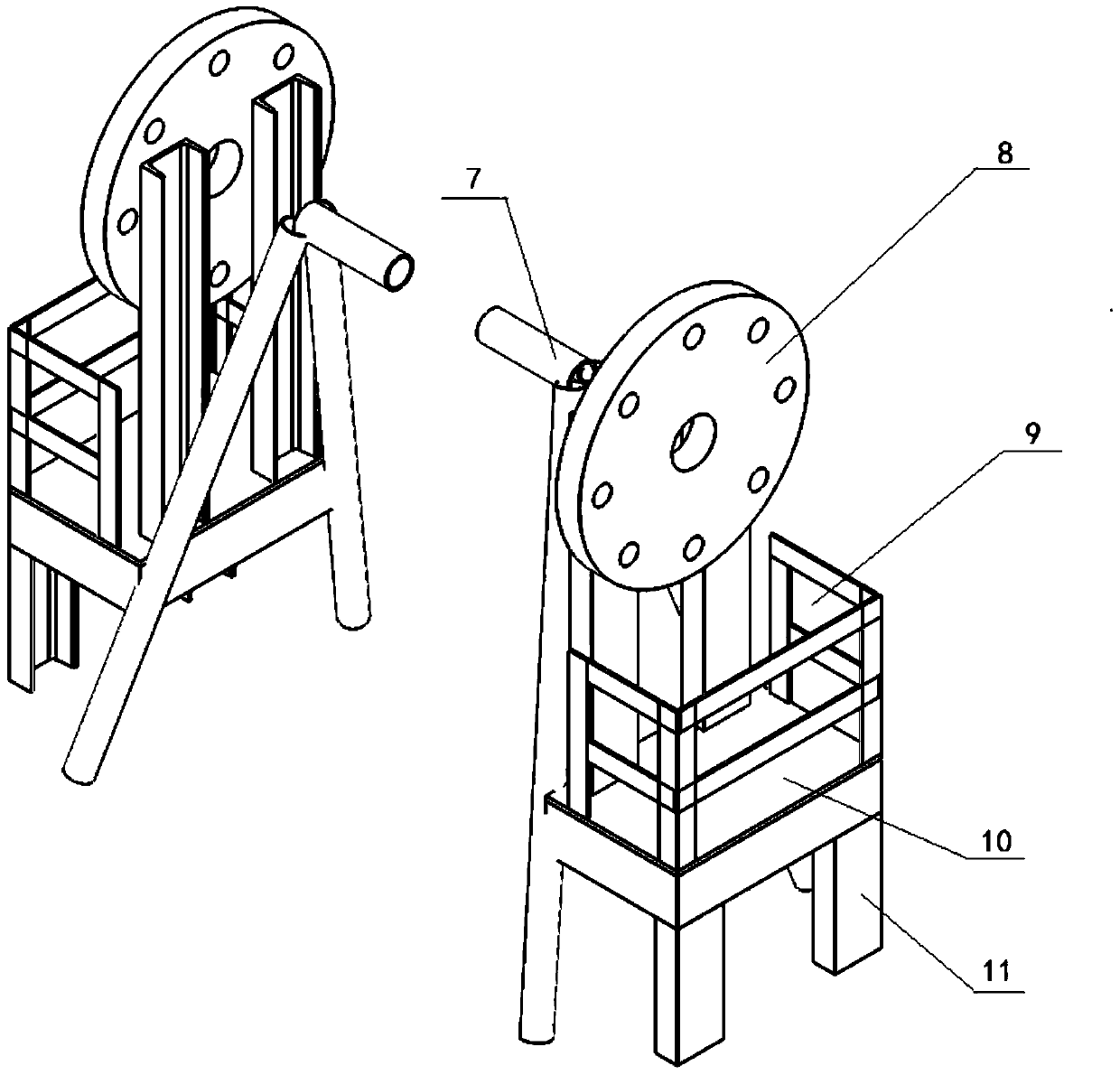

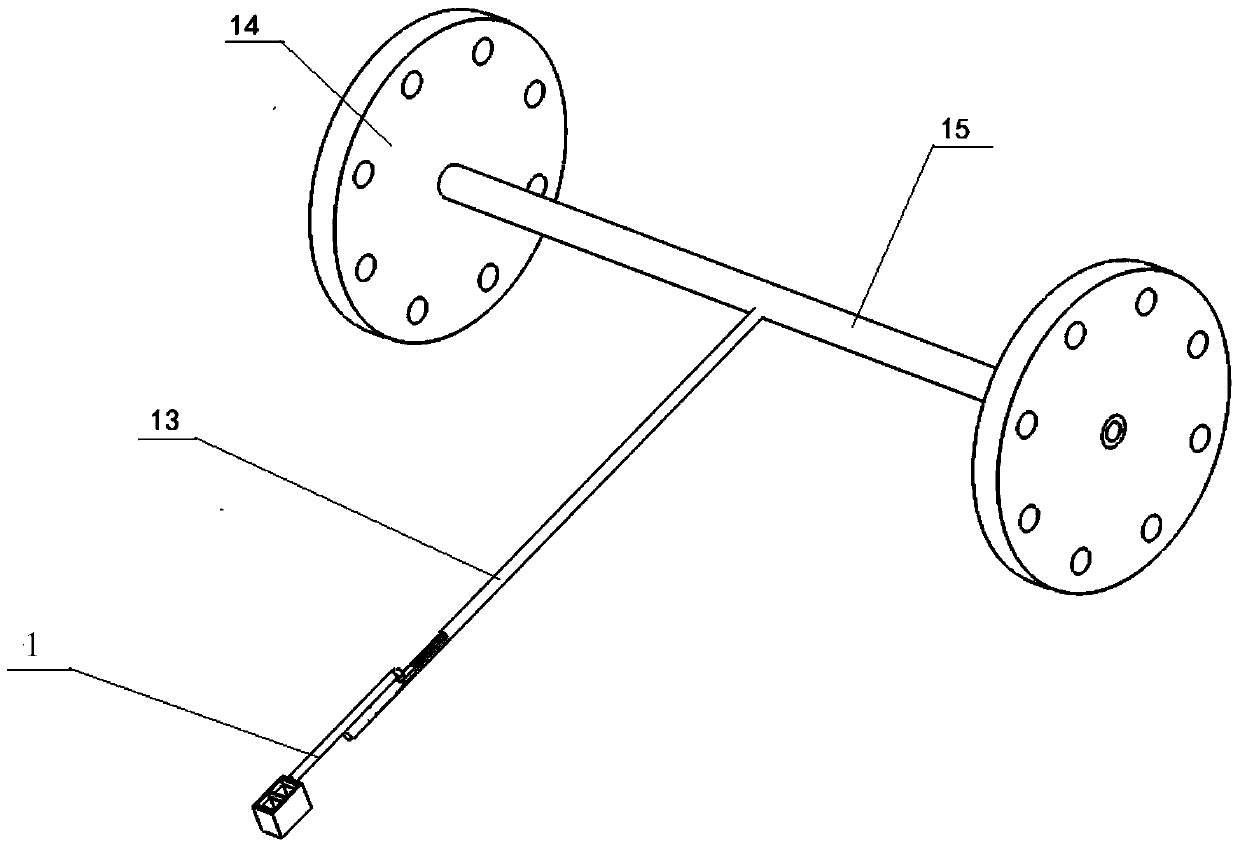

[0022] Such as Figure 1 to Figure 7 As shown, the blast furnace molten iron sampling device of the present invention includes a fixed bracket 2 arranged at the molten iron ditch, a rotating measuring gun 5 is arranged on the fixing bracket 2, a sampler 1 is arranged at the end of the rotating measuring gun 5, and the rotating rotating measuring gun 5 , the molten iron in the molten iron ditch can be scooped up by the sampler 1 and the molten iron sample is put into the sample collecting device 4 . Therefore, the blast furnace molten iron sampling device of the present invention can obtain a stable sample at a fixed position and insertion depth, avoiding the randomness and instability of sampling in the traditional way.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com