DC cable test terminal

A DC cable and terminal technology, which is applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of expensive DC cable terminals, inability to apply DC cables, and inability to use water terminals, etc., to reduce material costs and light weight , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the present invention, the content of the present invention will be further described below in conjunction with the accompanying drawings and examples.

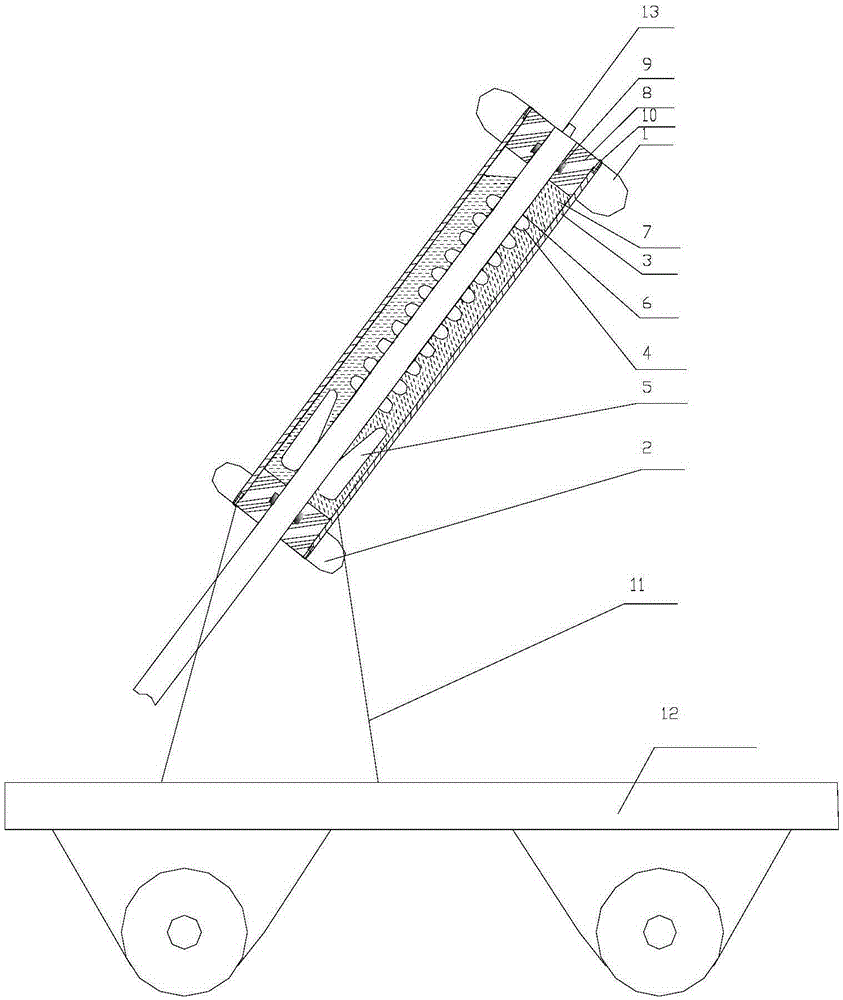

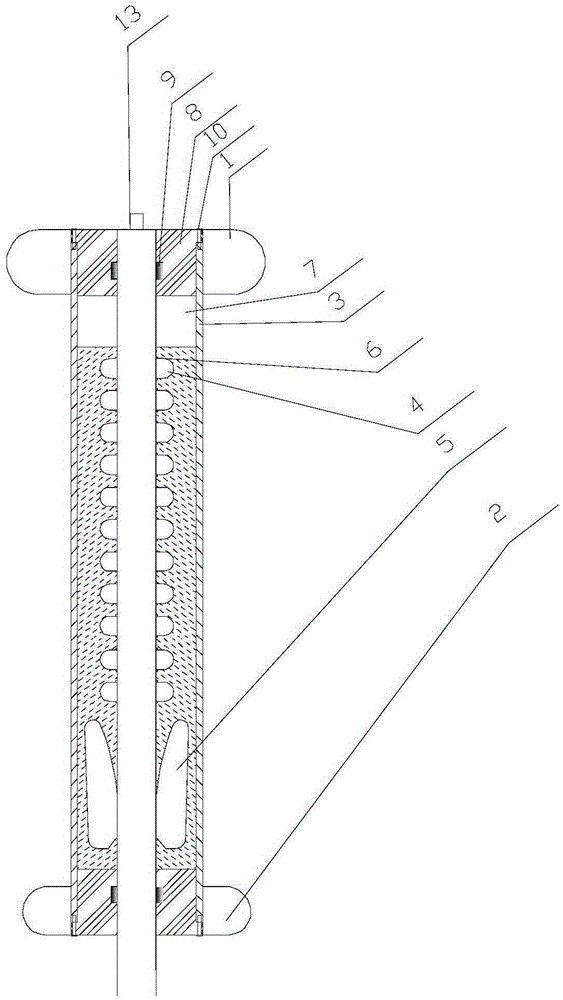

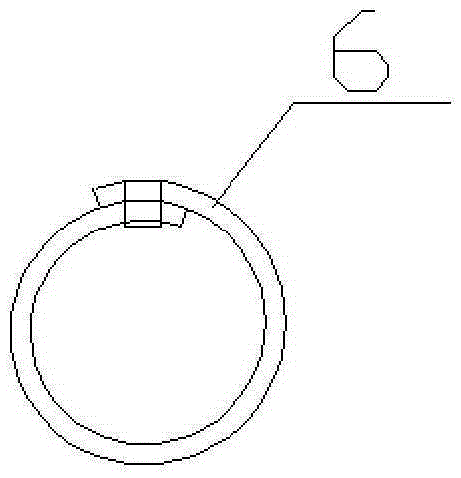

[0028] The structure of the DC cable test terminal provided by the present invention is as follows: Figure 1-2 shown. The DC cable test terminal includes an insulating cylinder 3, a voltage equalizing cover coaxially installed at both ends of the insulating cylinder 3, and a DC cable 13 axially penetrating through the insulating cylinder 3; the DC cable 13 in the insulating cylinder 3 An inflatable semi-conductive pressure equalizing ring 4 and an inflatable stress cone 5 with a variable inner diameter are installed coaxially.

[0029] The insulating barrel 3 includes a hollow cylindrical epoxy sleeve and an insulating sheath covering the epoxy sleeve.

[0030] In order to reduce the weight of the insulating cylinder 3, facilitate the installation of the DC cable test terminal, improve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com