Combined cable shielding card

A cable shielding, combined technology, applied in the direction of clamping/spring connection, connection contact material, etc., can solve the problems of difficult control of welding temperature and welding time, reduce cable core insulation, virtual welding or desoldering, etc. Combination detachable maintenance, easy to use, good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

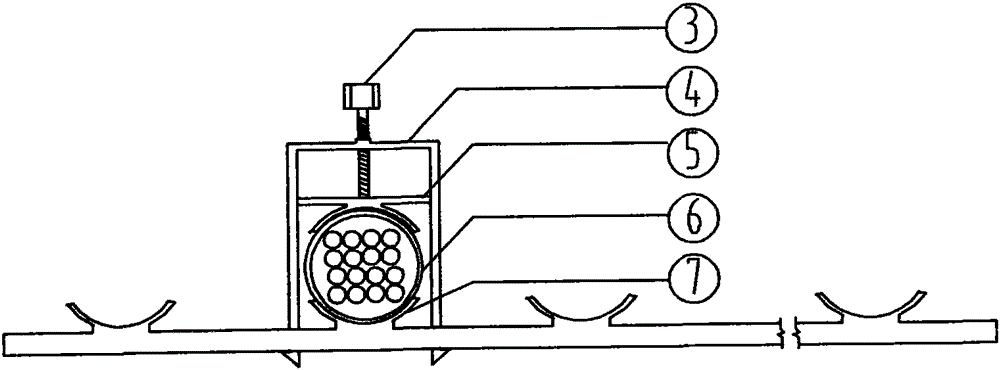

[0016] Combine below figure 1 and figure 2 The preferred embodiments of the present invention are further described:

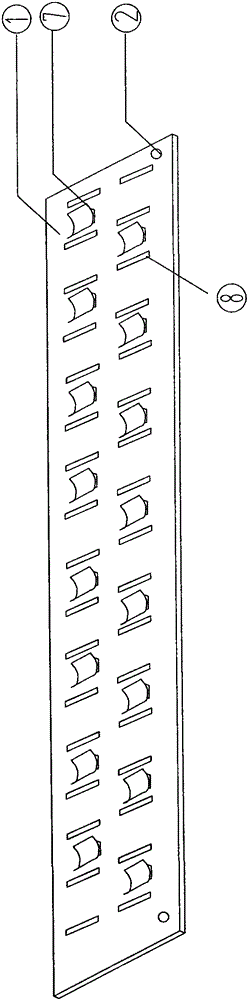

[0017] A combined cable shielding card, including a base plate 1 and a combined connection card, the base plate 1 is provided with a fixed crimping plate 7, and rectangular holes 8 are provided on both sides of the fixed crimping plate 7, the combination The combined connection card is correspondingly connected with the bottom plate 1 through the rectangular hole 8, and the combined connection card includes a groove-shaped card frame 4, and a movable crimping plate 5 is arranged in the card frame 4. The movable crimping plate 5 moves up and down in the card frame 4 . The movable crimping plate 5 is correspondingly connected with the crimping bolts 3 . Bolt holes 2 are provided on both sides of the bottom plate 1 . A combined cable shielding card of the present invention is squeezed by crimping bolts, so that the movable crimping plate and the fixed crimpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com