Cable protection pipe

A technology of cable protection tubes and protection tubes, applied in the field of power distribution maintenance, can solve problems such as the inability to grasp the real-time status of cable protection tubes in time, the impossibility of overall replacement, and cable damage, so as to improve the service life and use effect, and improve power supply Reliability, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

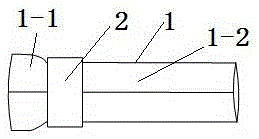

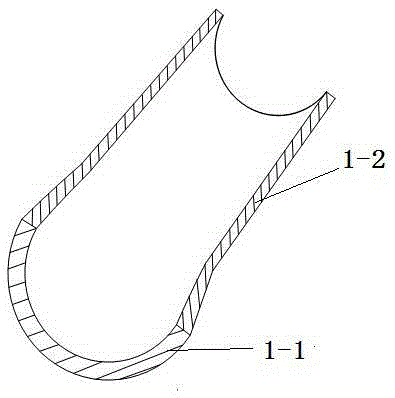

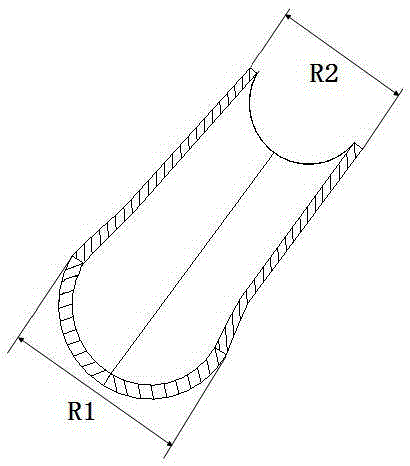

[0029] Embodiment 1: a kind of cable protection tube (see Figure 1-Figure 6 ), which includes two mutually butted protection tubes 1, the protection tube 1 is composed of an end tube head 1-1 and a tail straight tube 1-2, and the diameter of the end tube head 1-1 is larger than that of the tail The pipe diameter of the straight pipe 1-2, the pipe diameter of the end pipe head 1-1 is 21.6cm, and the pipe diameter of the tail straight pipe 1-2 is 18.8cm. The protection tube 1 is provided with two butted pipe pillows 2, and each pipe pillow 2 is provided with a semicircular pipe groove 2-1, and the joint of each pipe pillow 2 is provided with a trapezoidal pipe pillow slot 2- 2. The length L of the pipe pillow 2 is 24cm, the width W is 10cm, the height H is 12cm, the diameter R of the semicircular pipe groove 2-1 is 19cm, and the length of the long side of the trapezoidal pipe pillow slot 2-2 is 1.2cm , the length of the short side is 1.0cm, and the height is 0.8cm. Two butted ...

Embodiment 2

[0031] Embodiment 2: a kind of cable protection tube (see Figure 8 ), its structure and principle are basically the same as in Embodiment 1, the difference is that it is composed of three groups of cable protection tubes in Embodiment 1, wherein the first group of protection tubes 1 is inserted into the second group of protection tubes through its tail straight tube 1-2 The end tube head 1-1 of 1 is connected with the second group of protection tubes 1, and the second group of protection tubes 1 is inserted into the end tube head 1-1 of the third group of protection tubes 1 through its tail straight tube 1-2. The third group of protection tubes 1 are connected.

[0032] This embodiment is mainly used for laying cable protection tubes for directly buried cables.

[0033] During use, in order to ensure waterproof requirements, at this time, waterproof rubber should be clamped on both sides of the cable protection tube of the present invention, and a strong adhesive tape should...

Embodiment 3

[0034] Embodiment 3: a kind of cable protection tube (see Figure 9 ), its structure and principle are basically the same as in Embodiment 2, the difference is that it is composed of four sets of cable protection tubes in Embodiment 2 connected, and the other three faces of the pipe pillow 2 except the docking face are symmetrically arranged on the two sides and the bottom face 2 trapezoidal pipe pillow jacks 2-4, the pipe pillows 2 of the four groups of cable protection pipes are connected through the latches 2-3 in the side pipe pillow jacks 2-4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Wide w | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com