AGM partition plate processing method and device

A processing method and a separator technology, applied in the field of AGM separator processing methods and devices, can solve problems such as unevenness and incomplete drying, and achieve the effects of convenient placement, improved space utilization, and improved drying effect and drying uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

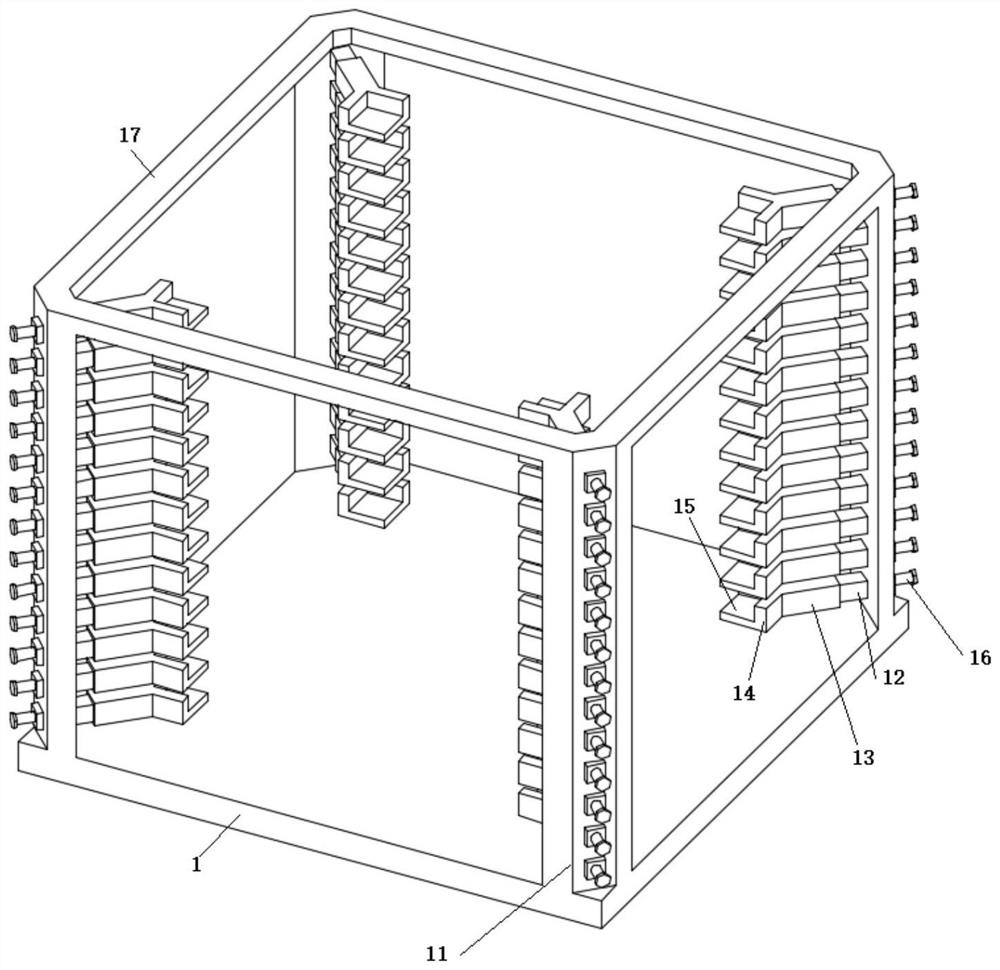

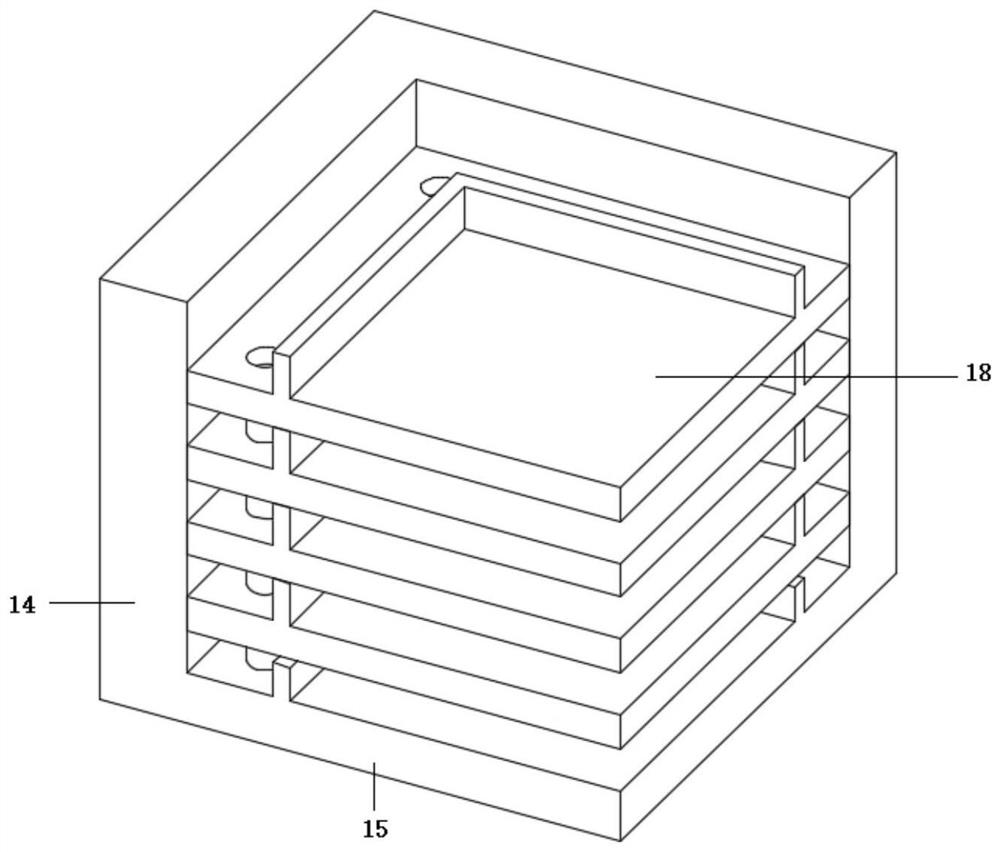

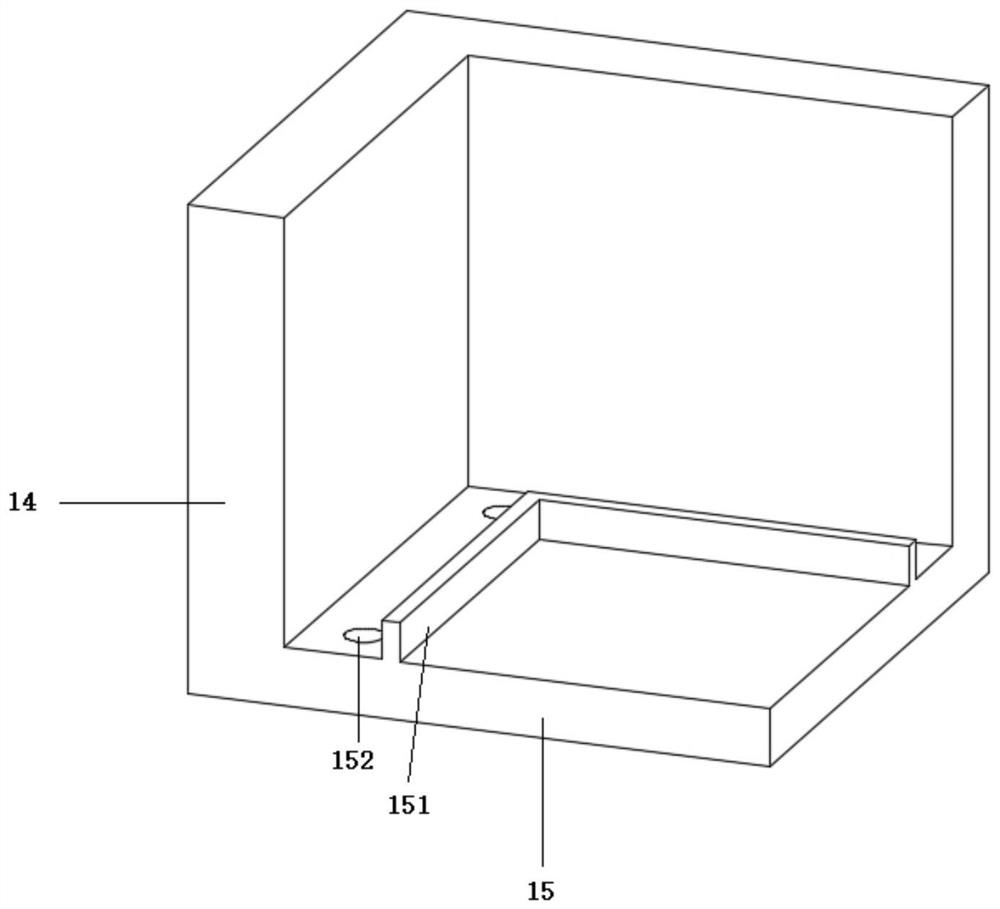

[0031] Embodiment 1, the present invention is a kind of AGM clapboard processing method, comprises the following steps:

[0032] Step1. Weigh various raw materials for making AGM partitions and mix to prepare mixed slurry;

[0033] Step2. Carry out negative pressure suction filtration and dehydration to the above mixed slurry to obtain a formed wet partition;

[0034] Step3. Cut the wet partition obtained above according to a certain length and width to form a semi-finished partition;

[0035] Step4. Put the obtained semi-finished partition into the drying device, and then put the drying device into the drying room for primary drying. After completing the primary drying, take it out of the drying room and let it cool naturally for 10 minutes; then push it into the drying room for secondary drying , After completing the second drying, take it out of the drying room and let it cool naturally for 5 minutes, and finally push it into the drying room for three times of drying.

[...

Embodiment 2

[0041] Embodiment 2, the present invention is a kind of AGM clapboard processing method, comprises the following steps:

[0042] Step1. Weigh various raw materials for making AGM partitions and mix to prepare mixed slurry;

[0043] Step2. Carry out negative pressure suction filtration and dehydration to the above mixed slurry to obtain a formed wet partition;

[0044] Step3. Cut the wet partition obtained above according to a certain length and width to form a semi-finished partition;

[0045]Step4. Put the obtained semi-finished partition into the drying device, and then put the drying device into the drying room for primary drying. After completing the primary drying, take it out of the drying room and let it cool naturally for 15 minutes; then push it into the drying room for secondary drying 1. After the second drying, take it out of the drying room and let it cool naturally for 10 minutes, and finally push it into the drying room for three times of drying.

[0046] In S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Liquid absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com