Grinder convenient for use

A technology of a grinder and a grinding mechanism, applied in the field of grinders, which can solve the problems of clutch damage, prolonging the time spent by users, and the inability to grind different materials, etc., so as to prolong the service life and use effect, improve grinding efficiency and grinding convenience Sexuality, the effect of guaranteeing product quality and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

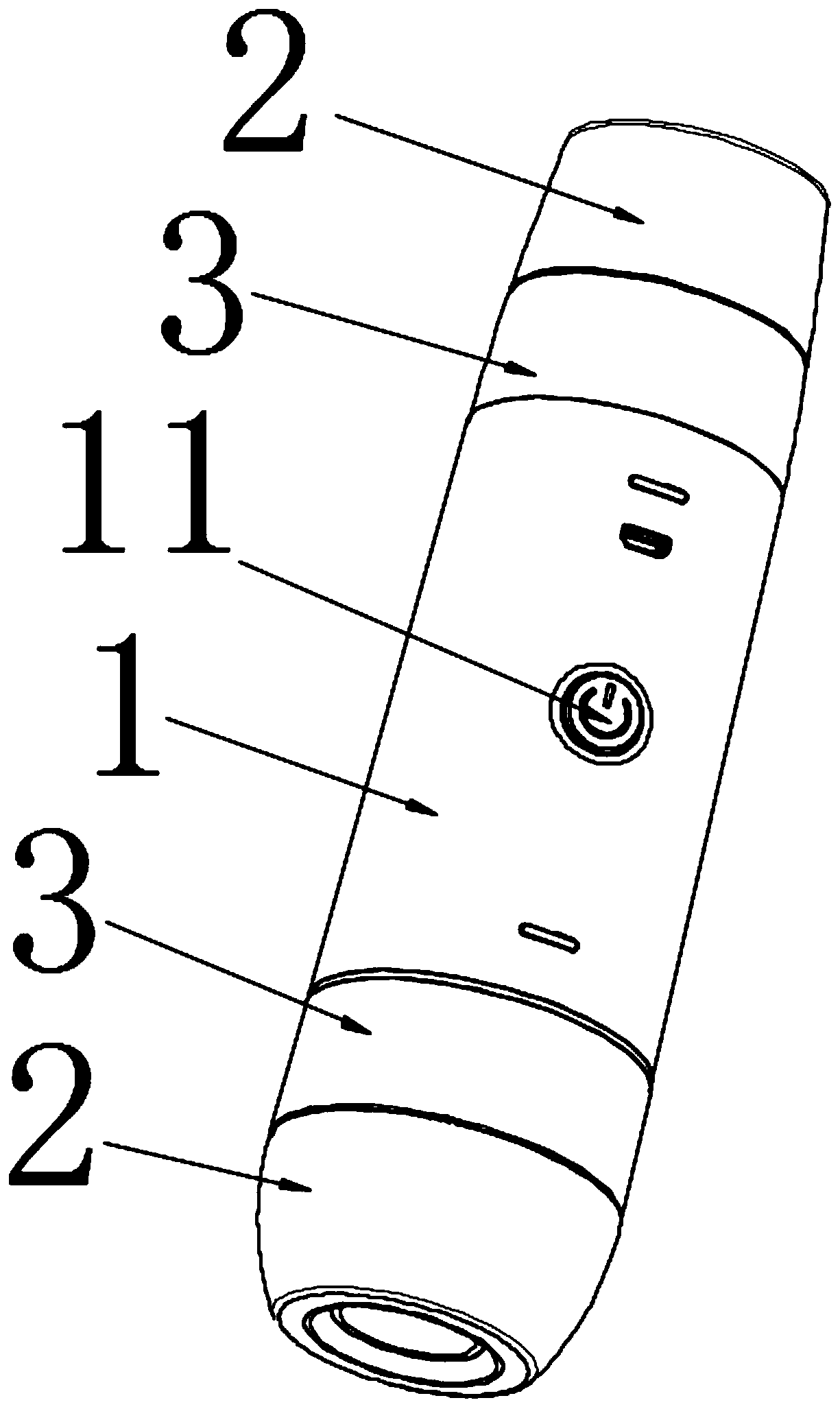

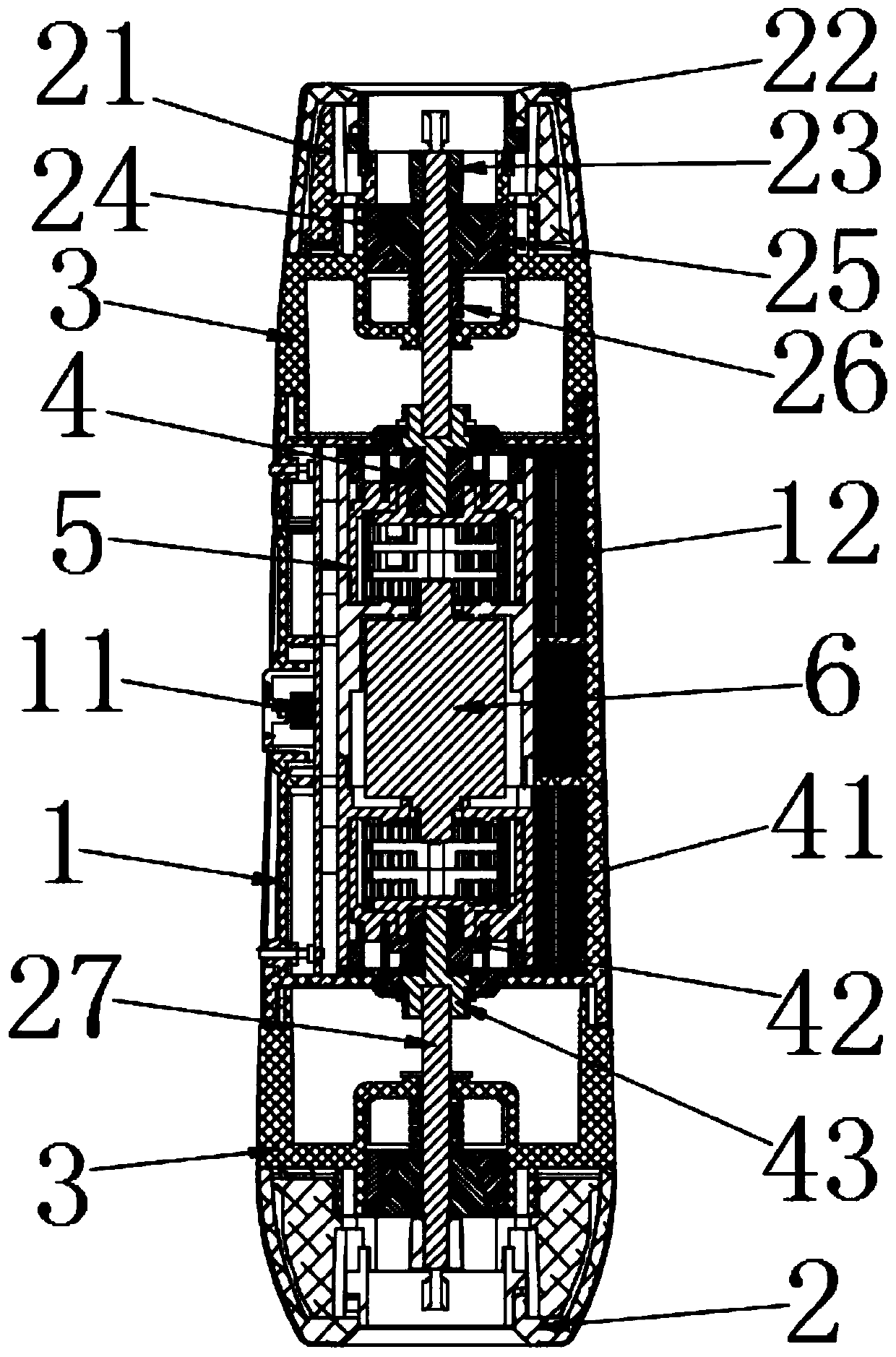

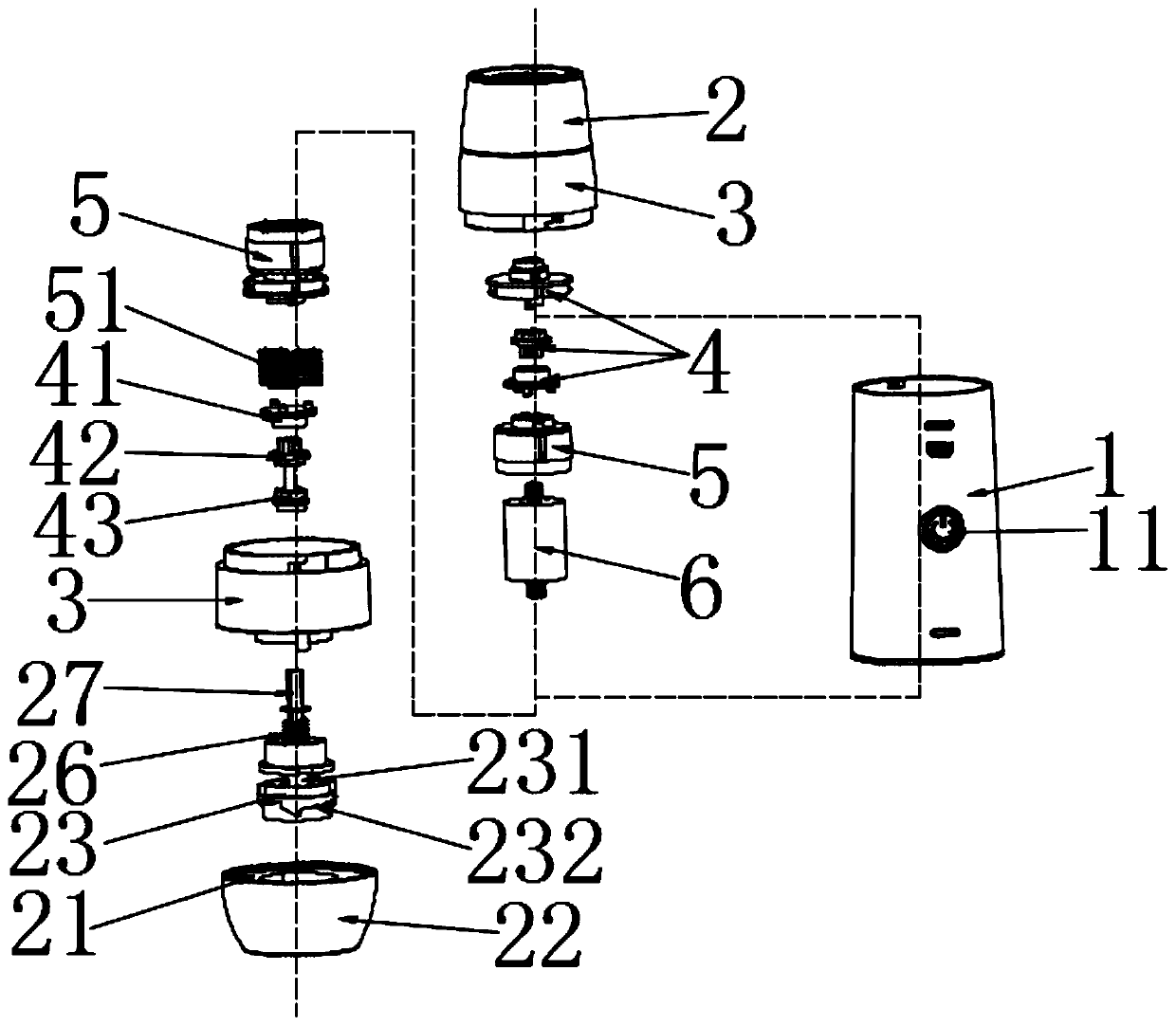

[0021] Such as Figure 1 to Figure 4 A kind of convenient grinder shown, comprises cylinder body 1, and the grinding mechanism 2 that is used for grinding material that detachably cooperates to be connected at two ends of cylinder body 1, and the interior of described cylinder body 1 is provided with motor 6, and described Both ends of the motor 6 are connected with a clutch mechanism 4 for controlling the linkage and disengagement between the motor 6 and the grinding mechanism 2. The driven block 43, one side of the driven block 43 is connected with a slide bar 431, the center of the slide bar 431 is slidably connected with the active block 42, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com