A kind of catalyst carrier and its supporting method and use

A catalyst and carrier technology, which is applied to the catalyst carrier and its supporting field, can solve the problems of reducing the overall density of the catalyst, high density of the catalyst carrier, and unsatisfactory operation effect, etc. The effect of low hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Catalyst

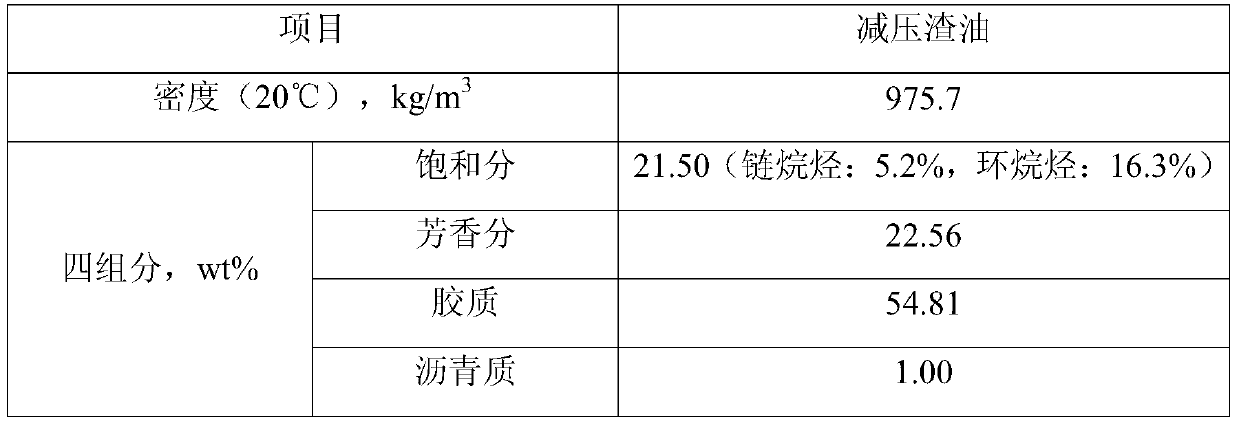

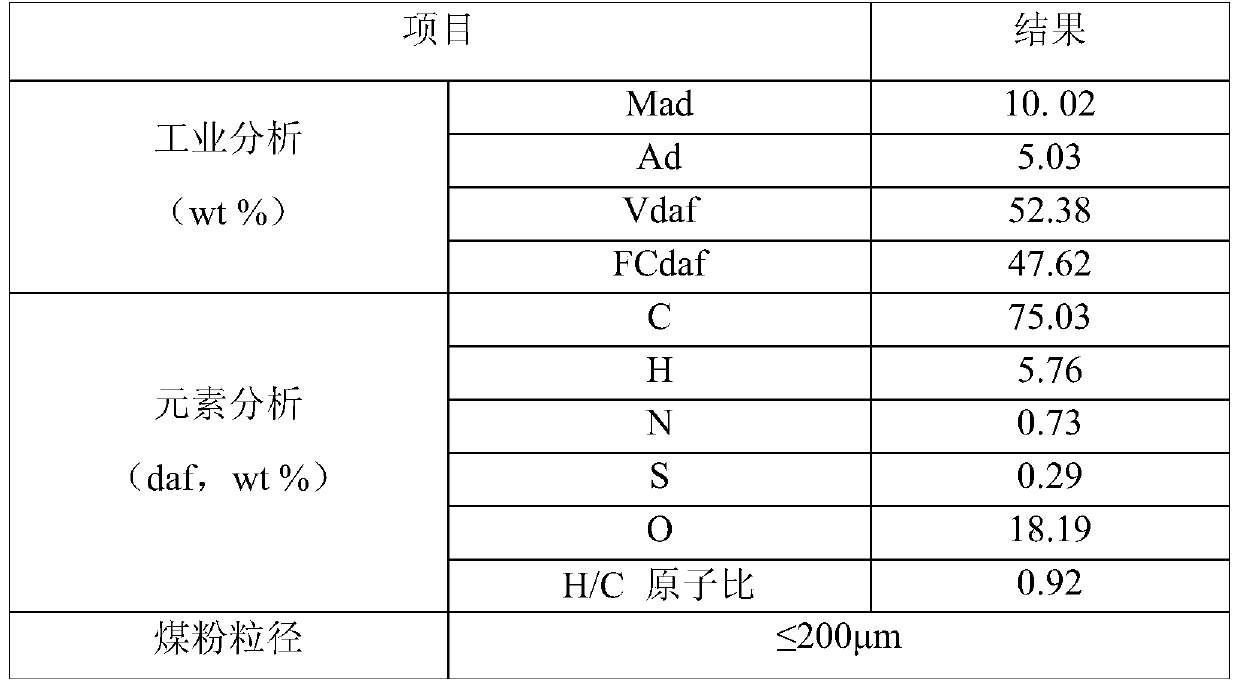

[0022] This example introduces a process in which vacuum residue and bituminous coal are used as raw materials, and the oil-coal mixing process is used for processing, and the oil-coal feed ratio is 1:1. The catalyst is an iron-based catalyst, the catalyst carrier is coal powder made of raw coal, and the bulk density of the carrier is 1.2g / cm 3 , specific surface area 800m 2 / g, the average pore diameter is 150nm, and the pore volume is 1.1cm 3 / g, the carrier accounts for 88wt% of the total mass of the catalyst.

[0023] The main process of loading is:

[0024] (1) Mix the pulverized coal with a particle size of ≤200 μm and the catalyst to prepare a catalyst / carrier slurry, and the operating temperature is 50°C;

[0025] (2) Catalyst / carrier slurry is filtered to obtain filter cake;

[0026] (3) The filter cake is dried under an inert gas environment, the drying temperature is 150° C., and the inert gas is nitrogen;

[0027] (4) Grinding the dried f...

Embodiment 2

[0037] The technique, raw material and feed ratio that present embodiment introduces are the same as embodiment 1. The catalyst is an iron-based catalyst, the catalyst carrier is coal powder made of raw coal, and the bulk density of the carrier is 2.5g / cm 3 , specific surface area 300m 2 / g, the average pore diameter is 50nm, and the pore volume is 0.4cm 3 / g, the carrier accounts for 20wt% of the total mass of the catalyst.

[0038] The load process is:

[0039] During the preparation of the catalyst, the ground carrier with a particle size of ≤200 μm is added to the raw material for catalyst preparation, the catalyst is formed on the surface of the carrier, dried in a nitrogen atmosphere and then ground to a particle size of ≤200 μm at a drying temperature of 150°C.

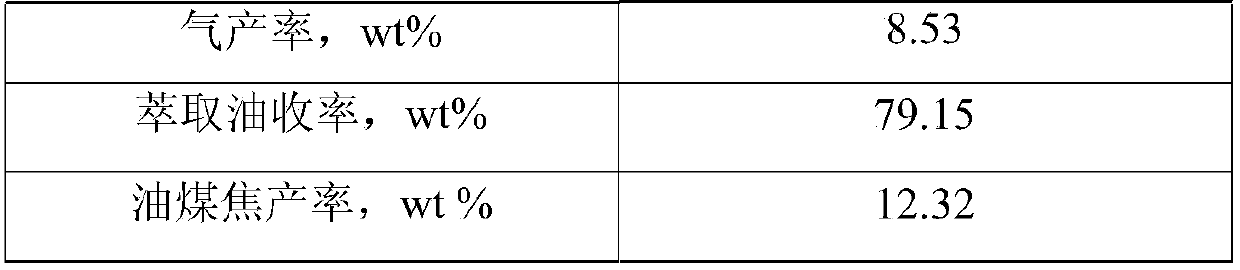

[0040] Reaction result data table:

[0041] Gas yield, wt%

[0042] The device has operated continuously for 8,000 hours, and the blockage and obvious wear of equipment, pumps, valves and pipeline...

Embodiment 3

[0044] The technique, raw material and feed ratio that present embodiment introduces are the same as embodiment 1. The catalyst is an iron-based catalyst, the catalyst carrier is coal powder made of raw coal, and the bulk density of the carrier is 3.3g / cm 3 , specific surface area 80m 2 / g, the average pore diameter is 5.0nm, and the pore volume is 0.16cm 3 / g, the carrier accounts for 8.8wt% of the total mass of the catalyst. This embodiment is a comparative example using the same ingredients but the range of each parameter is not within the scope of the present invention.

[0045] The load process is:

[0046] During the preparation of the catalyst, the ground carrier with a particle size of ≤500 μm is added to the raw material for catalyst preparation, the catalyst is formed on the surface of the carrier, dried in a nitrogen atmosphere and then ground to a particle size of ≤500 μm at a drying temperature of 150°C.

[0047] Reaction result data table:

[0048] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com