A brushing method and a roller coating device for rolling coating by using a roller

A rolling coating and brushing technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of paint waste, uneven brushing, etc., and achieve the effects of reducing waste, improving the working environment, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

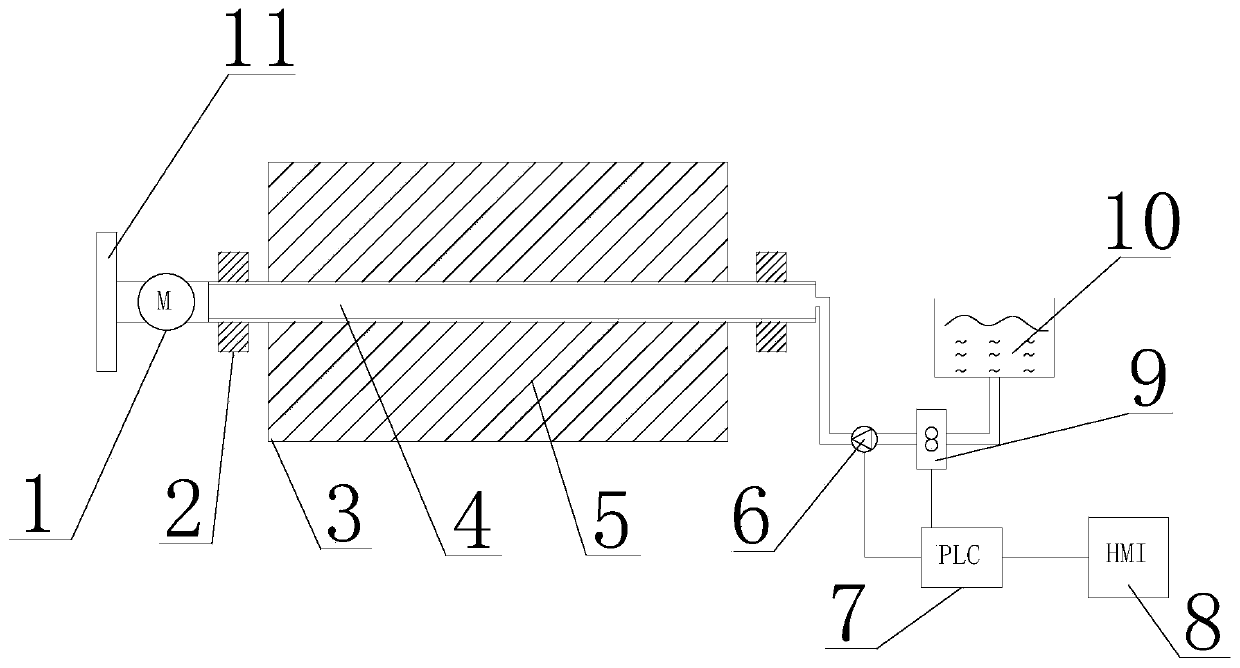

[0024] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

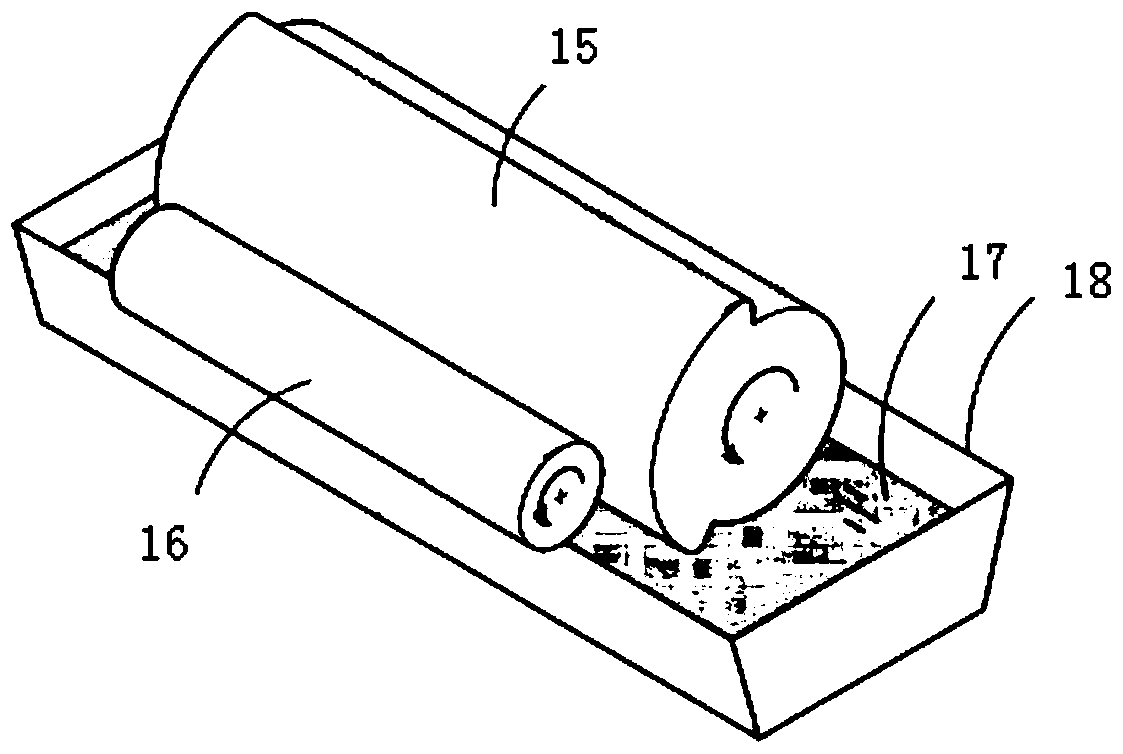

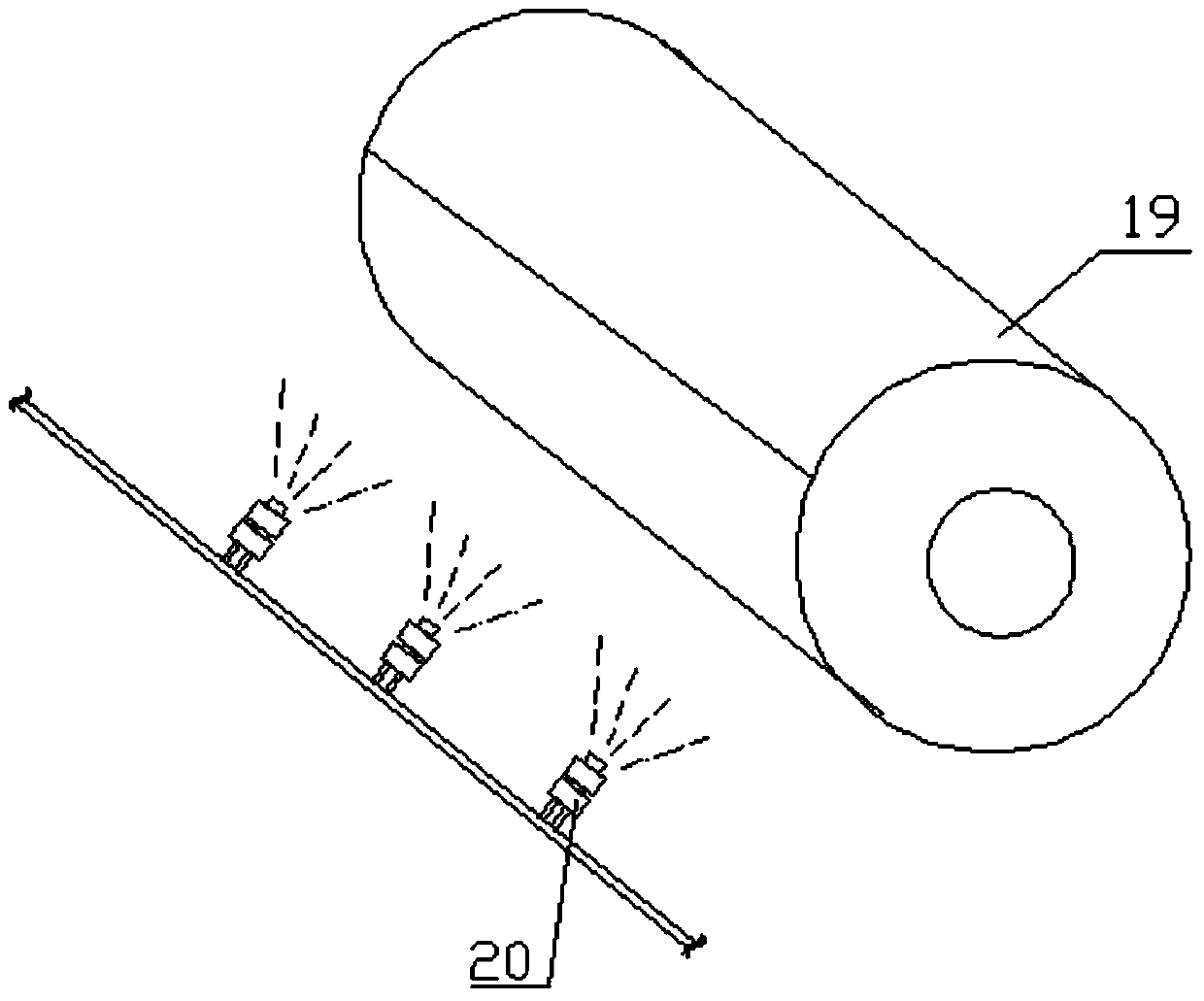

[0025] In the wood-based panel production line, most of the release agents or glues currently used are as attached figure 1 or attached figure 2 The method of roller coating or spraying is shown, but due to the limitations of the current roller coating device and the large demand for paint, it is still used as attached figure 2 Schematic method of spraying. The spraying device is simple and low in cost, but there are many disadvantages in the application process, such as uneven spraying, low utilization rate of paint, and poor working environment.

[0026] The present invention aims to provide a new coating method and a rolling coating device using rollers for rolling coating, which can improve the utilization efficiency of the coating material and make the coating more uniform while saving the coating material. The brushing method disclosed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com